Tube-nutunu mɔ̃a trɔa gakpo ƒe ʋuƒo wòzua tube to nuwɔwɔ tsitotsito ƒe ɖoɖo aɖe me. Ƒe sia ƒe la, wowɔa gakpo siwo wu metrik tɔn miliɔn 28 le xexeame katã. Mɔ̃ siawo subɔa dɔwɔƒewo abe ami kple gas, xɔtutu, kple elektrikŋusẽdɔwɔƒewo ene. Nuwɔwɔ ƒe ɖoɖoa dzea egɔme kple nusiwo wotsɔ wɔa nuawo me dzodzro, eye emegbe wowɔa wo, wotsɔa wo ƒoa woe, kple woƒe lolome be woakpɔ egbɔ be wowɔ pɔmpi ɖesiaɖe ɖe dzidzenu kɔkɔwo nu. Tube-nutunuwɔƒea zãa mɔ̃ tɔxɛwo tsɔ wɔa pɔmpiawo ƒe nɔnɔme, ƒoa wo, eye wotsoa wo pɛpɛpɛ. Dɔ vovovowo le mɔ̃ siawo me. Mɔ̃ nyuiwo wɔwɔ bia be woalé ŋku ɖe wo ŋu nyuie eye woalé ŋku ɖe wo wɔwɔ ƒe ɖoɖoa ŋu ɣesiaɣi, si kpena ɖe ame ŋu be woakpɔ ga pɔmpiwo ƒe didi le xexeame katã gbɔ.

Key Takeaways .

The Tube mill mɔ̃ trɔa gakpo strips wozua tubes. Ewɔa esia to afɔɖeɖewo abe ŋkuléle ɖe nu ŋu, nɔnɔmewɔwɔ, welding, lolome, fafa, kple lãɖeɖe ene zazã me. Ga la me léle kpɔ nyuie kple eƒe goawo ƒoƒo ɖe wo nɔewo ŋu kpena ɖe ame ŋu wòwɔa weld sesẽwo. Esia hã kpena ɖe ame ŋu be woawɔ tube nyuiwo. High-frequency welding ƒoa ƒu ɖe tube ƒe goawo ŋu kabakaba. Ewɔa nu sesẽwo na dɔ sesẽwo abe ami kple gas ene. Sizing mills kple straighteners kpena ɖe tube ƒe nɔnɔmewo kple lolomewo ŋu nyuie. Esia kpena ɖe ame ŋu be woawɔ ɖe dɔwɔƒea ƒe se sesẽwo dzi. Fotoɖemɔ̃wo kple nusiwo dea dzesi nu la léa ŋku ɖe mɔ̃awo ŋu ɣesiaɣi. Wokpɔa kuxiwo kaba. Esia wɔnɛ be mɔ̃wo nɔa dedie wu eye woɖea gbeɖuɖɔ dzi kpɔtɔna.

Nu xoxowo dzadzraɖo .

Ga gbadzɛwo me dzodzro .

Tube ƒe wɔwɔ dzea egɔme kple nusiwo wotsɔ wɔa nuawo me dzodzro. Dɔwɔlawo léa ŋku ɖe gakpo ɖesiaɖe ŋu nyuie. Woléa ŋku ɖe alesi wòdzenae ŋu eye wodzidzea eƒe lolome. Wodia kuxi siwo ate ŋu agblẽ nu le tube ƒe nyonyome ŋu. Kuxi siwo bɔ dometɔ aɖewoe nye:

gbagbã siwo zɔna to alo le goawo katã dzi .

Dutanuwo siwo wozi ɖe strip la me eye M-gblẽnuwo .

Gbɔɖeme gãwo, akɔtaɖonu, alo agbalẽxatsaxatsawo le strip la me .

Nuƒoƒo, ʋuʋudediwo, kple gouges tso mɔ̃wo me .

Strip goawo siwo gblẽ alo woxatsa .

Edges siwo nye ƒuƒuiƒe alo esiwo wotso la mesɔ o .

Woxatsa ɖe strip la me eye wògbãna le coil la me .

Ma nugbɔwo kple do suesuesuewo .

Wozi dzidzenu dzi le, dowo, kple dzesiwo tso agbalẽ xatsaxatsawo me .

Dɔwɔlawo zãa woƒe ŋkuwo kple dɔwɔnuwo tsɔ léa ŋku ɖe coil ɖesiaɖe ŋu. Wokpɔa egbɔ be coil la ƒe titrime kple kekeme sɔ. Coil ɖesiaɖe me léle ɖe asi le vevie ŋutɔ. Coil ɖesiaɖe xɔa eya ŋutɔ ƒe xexlẽdzesi tɔxɛ. Control system la dzraa nyatakaka siawo ɖo. Mill Test ƒe nyatakakawo ɖe gakpoa ƒe atike kple mɔ̃ɖaŋununya ŋuti nyatakakawo fia, esime wowɔe, kple afisi wòtso. Label, barcode, alo stamps kpena ɖe ame ŋu wòkplɔa coil la ɖo to ɖoɖoa me. To mɔ sia dzi la, woate ŋu akpɔ mɔ̃ ɖesiaɖe tso eƒe coil me. Esia kpena ɖe nuwo ŋu be woanɔ anukwareɖiɖi me eye woawɔ ɖe seawo dzi.

Nuƒoƒoƒu kple nuɖuɖu .

Ne wonya lé ŋku ɖe gakpoa ŋu ko la, eyia afɔɖeɖe si kplɔe ɖo dzi. Nusiwo wotsɔ ƒo ƒui la léa fli didi aɖe ɖe asi. Esia wɔnɛ be mɔ̃a ƒe fli la nɔa dɔ wɔm evɔ medzudzɔna o. Mɔ̃a kpɔa egbɔ be strip sɔ gbɔ ɖe eƒe wɔwɔ kple welding me ɣesiaɣi. Ne dɔwɔlawo trɔ coils gɔ̃ hã la, fli la yia edzi nɔa zɔzɔm. Automation le afisia fia be dɔ ʋɛ aɖewo koe woawɔ na amewo eye woawɔe kabakaba wu. Dzɔdzɔmeŋusẽ ƒe ɖoɖoa léa ŋku ɖe accumulator kple feeder la ŋu. Etrɔa duƒuƒu kple masɔmasɔ be wòawɔ dɔ nyuie wu. Ʋuʋu nyuie tso gakpo ƒuƒu dzi yi afɔɖeɖe si kplɔe ɖo dzi kpena ɖe ame ŋu be woawɔ tube nyuiwo eye wònana nuwo nɔa zɔzɔm kabakaba.

Uncoiling kple dzɔdzɔenyenye .

Uncoiler ƒe dɔwɔwɔ .

Tube wɔwɔ ƒe fli la dzea egɔme kple . Gaku siwo me womekɔa nu le o . Uncoiler sesẽ aɖe léa gakpoa ƒe coil la ɖe asi eye wòtrɔnɛ. Esia na be strip la ʋu yi afɔɖeɖe si kplɔe ɖo gbɔ. Dɔwɔlawo ɖoa uncoiler la ƒe duƒuƒu kple teteɖeanyi. Esia kpena ɖe nusianu ŋu wòƒua du nyuie. Uncoiler la wɔa dɔ kple coil ƒe lolome kple kpekpeme vovovowo. Ekpɔa egbɔ be nusiwo sɔ gbɔ nɔa anyi ɣesiaɣi. Uncoilers yeyewo zãa ʋu tɔxɛwo kple dijitaal dzikpɔmɔ̃wo. Esiawo kpena ɖe ame ŋu wòtrɔa roll ƒe ɖoƒewo eye wònana be woaxe fe ɖe eta. Tabla si le ete la yɔ nyatakaka siwo bɔ ɖe mɔ̃ siwo me womekɔa nu le o kple esiwo me woɖɔa wo ɖo me:

Parameter . |

Emenuwo |

Nuwo ƒe titrime ƒe ŋutete . |

0.010' va ɖo 0.450' (ga si wotsɔ ƒo ƒui) |

Nuwo ƒe kekeme ƒe ŋutete . |

12' va ɖo 72' (le kpekpem ɖe eŋu le biabia nu) |

Standard payout speed . |

Afɔ 0 va ɖo 80 le miniti ɖeka me . |

Ŋutinuwo |

Ʋu siwo trɔna kabakaba, dijitaal agbalẽ xatsaxatsa ƒe nɔƒe ƒe dzesiwo, gege ɖe eme/dona ɖe ame ŋu ƒe kpekpeɖeŋunamɔ̃wo, wowɔe wònyo wu na HSLA ƒe nuzazãwo . |

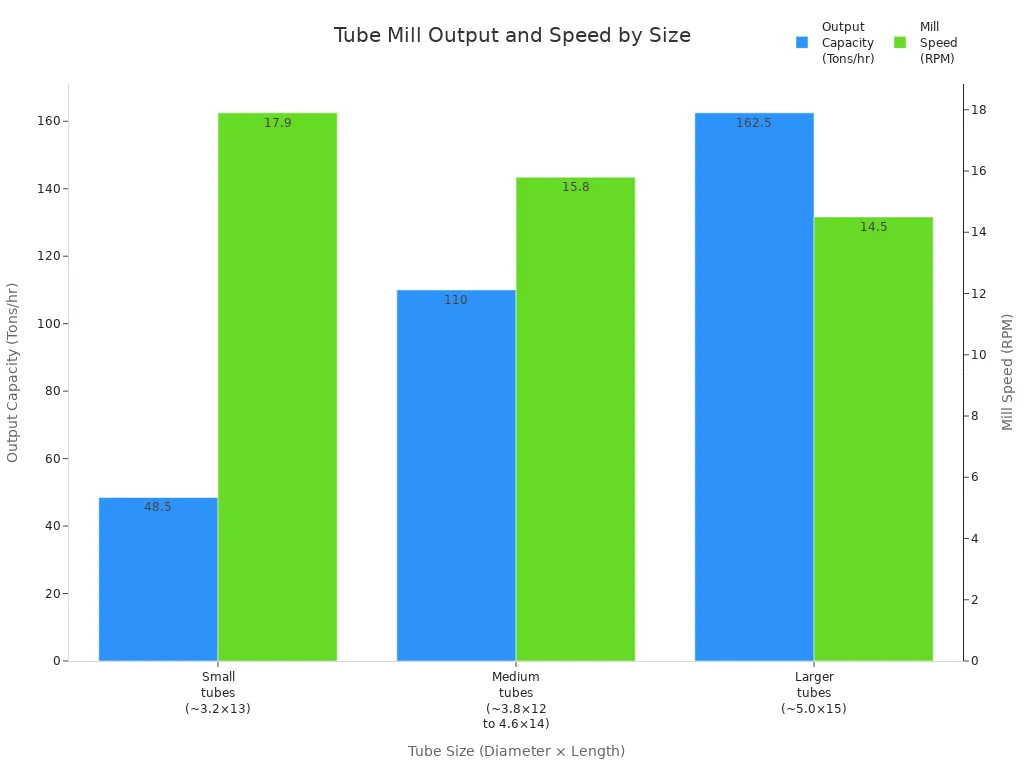

Alesi uncoiler la wɔa dɔ nyuie kpɔa ŋusẽ ɖe fli bliboa dzi. Uncoilers siwo zɔna kabakaba kpena ɖe wo ŋu wowɔa tube geɖe le gaƒoƒo ɖesiaɖe me. Nusiwo woaɖe tso eme ate ŋu anye tɔn 45 va ɖo 170 le gaƒoƒo ɖeka me. Esia nɔ te ɖe tube ƒe lolome dzi. Taɖodzinu si le ete la ɖe alesi dodo kple duƒuƒu trɔna kple tube ƒe lolome fia:

Strip dzɔdzɔe .

Le uncoiling megbe la, . Strip yi ɖe nu dzɔdzɔe aɖe me . Afɔti atɔ̃ va ɖo adre le mɔ̃ sia ŋu. Rollers la ɖea bends kple curves tso strip la me. Dzɔla la nɔa anyi ɖe uncoiler la gbɔ tututu. Ehea fli la tso coil la dzi tututu. Emegbe enaa nuɖuɖua ƒe akpa si woɖe la nɔa afɔɖeɖe si kplɔe ɖo me. Mɔ̃ aɖewo ƒoa nuɖuɖu kple wo dzadzraɖo nu ƒu ɖekae. Wozãa mɔ̃ sesẽwo hena duƒuƒu nyuie wu eye wowɔa nu wòdea pɛpɛpɛ wu. Mɔ̃ siawo kpena ɖe ame ŋu be strip la nɔa zɔzɔm eye wònɔa fli me.

Dzadzraɖo zãa tensile-bending mɔ̃ɖaŋununya. Strip la ʋãna toa bending, drawing, kple tension rolls me. Rollers-awo bɔbɔa strip la le mɔ tɔxɛ aɖe nu. Esia ɖɔa nɔnɔme ƒe kuxiwo abe edge waves kple centre buckles ene ɖo. Dɔwɔwɔa ɖea nuteɖeamedzi si susɔ hã ɖa. Esia wɔnɛ be strip la nɔa gbadzaa eye wònɔa klalo na wɔwɔ. Dzadzraɖo nyui hiã na tube siwo le nyonyome nyuie. Ekpena ɖe ame ŋu hã be mɔ̃a ƒe lolomewo nanɔ eteƒe le ewɔwɔ me.

Tube wɔwɔ ƒe ɖoɖo .

Roll wɔwɔ .

Tube ƒe wɔwɔme ƒe ɖoɖoa dzea egɔme ne gakpoa ƒe ʋuƒoa yi ɖe . Roll wɔwɔ ƒe akpa aɖe le tube mill mɔ̃. Strip la trɔna zua pɔmpi si le goglo alo eƒe nɔnɔme to afɔɖeɖe geɖe me. Dɔwɔlawo zãa mɔ̃ tɔxɛwo tsɔ kpɔa egbɔ be afɔɖeɖe ɖesiaɖe naa nu ɖeka ma ke. Afɔɖeɖe siwo wowɔna le ERW tube-nutunu me la dometɔ aɖewoe nye:

Uncoiling and preparation: Gaku la me mekɔ o eye wowɔe wòle gbadzaa. Esia wɔa fli didi aɖe si le gbadzaa si sɔ na wɔwɔ.

wɔwɔ: Flat strip la ʋãna toa forming roll geɖe me. Agbalẽ xatsaxatsa ɖesiaɖe bɔbɔa strip la vie wu. Esia trɔa asi le eŋu wòzua pɔmpi goglo alo esi wowɔ ɖe ɖoɖo nu.

Edge preparation: Dɔwɔlawo dzraa nu ɖo eye wodzraa nugbɔwo ɖo. Esia kpena ɖe eŋu be weld seam si le gbadzaa eye wòdzudzɔa kuxiwo le pɔmpia me.

Welding: ERW Tube Mill zãa welding si ƒe ɣeyiɣi de ŋgɔ tsɔ ƒoa ƒu ɖe goawo ŋu. Esia wɔnɛ be seam sesẽ aɖe nɔa mɔ̃a ŋu.

Sizing and shGas & Oilng: le welding megbe la, tube la toa sizing rolls me. Agbalẽ xatsaxatsa siawo trɔa woƒe lolome kple nɔnɔme. Wowɔa pɔmpi siwo le goglo, dzogoe ene me, alo dzogoe ene me tɔ.

Fafa kple eɖɔɖɔɖo: pɔmpi yeyea fa miamiamia eye wòtoa mɔ̃ siwo wotsɔna dzraa nu ɖo me. Esia ɖea bend alo twist ɖesiaɖe ɖa.

Lãɖeɖe kple ewuwu: Tube la nye . Lãe ɖe didime siwo sɔ me . Dɔwɔlawo ate ŋu awɔ nuwuwu hã abe kaƒoƒo alo nutrenu ene.

Quality inspection: Woléa ŋku ɖe pɔmpi ɖesiaɖe ŋu to ŋkuléle ɖe nu ŋu kple dodokpɔ me gbegblẽ manɔmee me. Esia nana be weld la nyo eye eƒe lolome sɔ.

Nubablɛwo kple wo ɖoɖoɖa: Wotsɔa pɔmpi siwo wowɔ vɔ la ƒoa ƒu, wodea dzesii, eye wowɔa wo dzra ɖo be woatsɔ wo aɖo ɖe wo.

Kpekpeɖeŋu: Mɔ̃ɖaŋudɔwɔlawo zãa 'seƒoƒo ƒe nɔnɔmetata' tsɔ wɔa ɖoɖo ɖe agbalẽ xatsaxatsa ƒe afɔɖeɖewo ŋu. Kpɔɖeŋu sia ɖe alesi strip la bɔbɔna le akpa ɖesiaɖe me fia. Ekpena ɖe ame ŋu wòwɔa dɔwɔnu siwo sɔ na ERW tube mill.

Ele be woawɔ ɖoɖo ɖe agbalẽ xatsaxatsa wɔwɔ ƒe ɖoɖoa ŋu nyuie. Mɔ̃ɖaŋudɔwɔlawo taa cross-sections, wobua strip width, eye wowɔa roll la ƒe ɖoɖo. Afɔɖeɖe siawo kpena ɖe pɔmpia ŋu be woawɔ ɖe se sesẽwo dzi.

Edge ƒe ɖoɖowɔwɔ .

Edge alignment le vevie ŋutɔ na pɔmpi nyuiwo wɔwɔ le ERW tube mill me. Ne strip edges sɔ la, welding wɔa seam sesẽ aɖe. Ne goawo meɖo fli o la, kuxiwo ate ŋu adzɔ. Ðoɖo gbegblẽ ate ŋu ahe weld alo do siwo gbɔdzɔ vɛ. Kuxi siawo nana pɔmpia gbɔdzɔna.

Egbegbe tube mill mɔ̃wo zãa tracking tɔxɛ kple roll tɔtrɔwo tsɔ naa goawo nɔa fli me. Ʋuʋu sue aɖe gɔ̃ hã le welding me ate ŋu atrɔ pɔmpia. Dɔwɔƒewo ƒe sewo, abe Apispec5L ene, gblɔ be mele be masɔmasɔ kple burr nawu 1.5mm o. Ne egasɔ gbɔ wu la, weldwo ate ŋu anye esiwo mesɔ o, gbagbãƒewo ate ŋu adzɔ, eye gbeɖuɖɔ ate ŋu adze egɔme.

Nugbɔwo dzadzraɖo, abe beveling ene, hã kpena ɖe weld la ŋu. Beveled edges na weld la yi goglo wu eye wòakaka nuteɖeamedzi nyuie wu. Gake ne woɖe bevels is not to alo too much off la, ke teƒe siwo gbɔdzɔ ate ŋu anɔ pɔmpia ŋu. Ele be dɔwɔlawo nalé ŋku ɖe afɔɖeɖe siwo woawɔ ŋu, akpɔ mɔ̃wo dzi, eye woatrɔ ɖoɖo siwo ana goawo nanɔ fli me.

MIDE DZESII: Erw tube mill la ƒe goawo nana be weldwo nyona ɖe edzi eye wòkpena ɖe tube la ŋu wòdidina wu. Esia le vevie na dɔ sesẽwo abe ami, gas, kple xɔtutu ene.

Tube Mill Welding ƒe Dɔwɔna .

HIGH-Frequency Welding (ERW) .

The ERW tube mill ƒoa steel strip edges nu ƒu to high-frequency induction welding zazã me. Mɔnu sia zãa elektrikŋusẽ sesẽwo tsɔ doa dzo na goawo kabakaba ŋutɔ. Nugbɔwo xɔa dzo ale gbegbe be woate ŋu alé ɖe wo nɔewo ŋu evɔ womatsɔ naneke akpe ɖe eŋu o. Mɔ sia zɔna kabakaba eye wòwɔa dɔ nyuie, eyata wozãnɛ geɖe tsɔ wɔa pɔmpi geɖe.

Dɔwɔlawo fiaa mɔ strip la toa agbalẽ xatsaxatsawo me vaseɖe esime goawo ka. Fifia ƒe elektrikŋusẽ si sɔ gbɔ la doa dzo ɖe goawo dzi va ɖoa dzoxɔxɔ si sɔ gbɔ. Nyaƒoɖeamenu ƒe agbalẽ xatsaxatsawo tutua nugbɔ dzodzoeawo ɖe wo nɔewo ŋu be woawɔ weld sesẽ aɖe. Esia wɔa nusi wotsɔna ƒoa nui si zɔna to pɔmpi bliboa dzi. ERW tube mill la nana welds la sẽna eye wòwɔa pɔmpi geɖe kabakaba.

Mɔ vovovowo li siwo dzi woato aƒo pɔmpiwo nu ƒu ɖe dɔwɔƒewo. Tabla si le ete la fia welding mɔnu veviwo kple alesi wotsɔa wo sɔnae:

Welding mɔnu . |

Nuɖᴐɖᴐ |

Viɖewo . |

Seɖoƒewo . |

Dɔwɔwɔ nyuie ƒe tsɔtsɔ sɔ kple wo nɔewo . |

Tig Welding (Tungsten Gas si mewɔa dɔ o) . |

Ezãa tungsten electrode kple gas tsɔ wɔa weld siwo le dzadzɛ. |

Ewɔa weld dzadzɛwo kple tɔtɔ sue aɖe ko; Ewɔa dɔ le nu geɖe ŋu; Dzoxɔxɔ kple weld dzi kpɔkpɔ nyuie . |

duƒuƒu blewu; Hiahiãwo ƒe dɔwɔla bibiwo . |

Duƒuƒu blewu fia be woawɔ pɔmpi ʋɛ aɖewo; Ezãa ŋusẽ geɖe wu elabena ele blewu . |

Plasma ƒe ƒoƒo . |

Abe TIG ene gake ezãa plasma hot plasma arc na pɔmpi siwo le ʋeʋẽm. |

duƒuƒu kabakaba wu; weld siwo goglo wu; Dzoxɔxɔ dzi ɖuɖu nyuie . |

ga si wozãna ɖe eŋu wu; Ezazã sesẽ wu . |

Duƒuƒu kabakaba naa pɔmpi geɖe wu; Edzraa ŋusẽ ɖo elabena ewɔa dɔ kabakaba . |

Welding si wozãna zi geɖe (HFW) . |

Ezãa elektrikŋusẽ si sɔ gbɔ ŋutɔ tsɔ ƒoa pɔmpiwo nu ƒu kabakaba. |

kabakaba ŋutɔ; Ewɔa pɔmpi geɖe . |

Ezãa ŋusẽ geɖe wu le elektrikŋusẽ sesẽwo ta . |

kabakaba ŋutɔ eye wònyo na ɖoɖowɔɖi siwo me vovo mele o . |

Elektrikŋusẽ ƒe Tsitretsitsi ƒe Welding (ERW) . |

Ezãa dzoxɔxɔ si tsi tre ɖe eŋu tsɔ ƒoa pɔmpiwo nu ƒu. |

pɛpɛpɛ eye kakaɖedzi le eŋu; Ezãa ŋusẽ si mebɔ o . |

Ezãa ŋusẽ si mesɔ gbɔ wu HFW o . |

Eléa fɔ ɖe ŋusẽzazã nyuie kple weld nyuiwo wɔwɔ ŋu . |

ERW Tube Mill la wɔa dɔ kabakaba eye wòwɔa pɔmpi geɖe gbesiagbe. Ate ŋu ana pɔmpi siwo ƒe lolome kple titrime le vovovo. ERW Tube Mill hã nana be weld seam la nɔa sesẽm. Esia le vevie na pɔmpi siwo wozãna le xɔtutu, ami, gas, kple dɔ sesẽ bubuwo wɔwɔ me.

De dzesii: High-frequency induction welding le ERW tube mill me wɔa weld sesẽwo kabakaba. Esia kpena ɖe pɔmpia ƒe nutunua ŋu be wòayi edzi anɔ du dzi madzudzɔ o.

Weld bead ɖeɖeɖa .

Ne wowɔe vɔ la, ERW tube-nutunu la gblẽa dzonu sue aɖe ɖe seam la dzi. Kuku sia le pɔmpia ƒe eme kple egodo siaa. Weld bead la ɖeɖe ɖa le vevie na pɔmpi si le gbadzaa eye eƒe nyonyome nyo. Bead la ɖeɖeɖa nana pɔmpia dzena nyuie wu eye wòwɔa dɔ nyuie wu.

Dɔwɔlawo zãa dɔwɔnu siwo wotsɔ ɖaa nu siwo ƒe aɖaŋuɖoɖowo le abe anyinuwo ene tsɔ tsoa gota bead la. Dɔwɔnu siawo le ERW tube-nutunu la dzi eye wotsoa bead la ne pɔmpia le ʋuʋum. Dɔwɔnu si sɔ la tiatia kple ewɔwɔ ɖaɖɛ le vevie. Dɔwɔnu nyuiwo tɔ te dzesiwo eye wokpena ɖe pɔmpia ŋu wòsɔna kple nu susɔeawo. Dɔwɔnu gbegblẽwo alo aɖaŋuɖoɖo siwo me mekɔ o ate ŋu ana pɔmpia nazu ƒuƒlu eye wòavuvu kabakaba.

Dɔwɔƒe aɖewo zãa robotwo tsɔ ƒoa weld-ku la, vevietɔ na pɔmpi gãwo alo esiwo le ʋuʋu ɖi. Robot siawo ʋãna le mɔ geɖe nu eye wozãa laser sensorwo tsɔ dia bead la. Robot la ƒoa bead la ɖe anyi va ɖoa esi mede 0.1 mm o eye wònana tɔtrɔwo nɔa 0.05 mm te. Esia wɔnɛ be pɔmpia ƒe anyime nɔa blɔ ŋutɔ eye wòwɔa se sesẽwo dzi.

Robotwo zãa abrasive alidziblanu tsɔ ƒoa dzonuawo kabakaba eye wonaa pɔmpia nɔa nyuie. Mɔ sia bɔ ɖe tube-nutunu yeyewo me elabena ewɔa dɔ kabakaba eye wònɔa te sesĩe. Pɔmpia dona nyuie eye wòle klalo na afɔɖeɖe siwo kplɔe ɖo.

Kpekpeɖeŋu: Weld bead si le ERW tube mill la ɖeɖe ɖa ɣesiaɣi kpena ɖe pɔmpia ŋu wòdzena nyuie eye wòwɔa dɔ nyuie.

lolome kple nɔnɔmewɔwɔ .

Sizing Mill .

Sizing mill la le vevie ŋutɔ le mɔ̃wo wɔwɔ me. dɔwɔlawo zãnɛ tsɔ ɖoa mamlɛtɔ . Pɔmpi ƒe lolome . Wotrɔa asi le eƒe didime kple gli ƒe titrime ŋu. Agbalẽ xatsaxatsa geɖe le nutunuwɔƒea si ƒoa pɔmpi si wotsɔ ga wɔe la. Agbalẽ xatsaxatsa ɖesiaɖe tea pɔmpia ne ele ŋgɔ yim. Esia kpena ɖe pɔmpia ŋu wòkpɔa eƒe dɔa ƒe lolome nyuitɔ.

Sewo abe ASTM A519 ene gblɔ alesi wòle be pɔmpia ƒe lolome nagogoe. Gli ƒe titrime ateŋu atrɔ abe 10% va ɖo 12.5%. Esia nɔ te ɖe pɔmpia ƒe lolome kple eƒe titrime dzi. Le kpɔɖeŋu me, pɔmpi si ƒe didime nye inch 10 eye glia ƒe titrime nye inch 2.5 ate ŋu anɔ ememe tso inch 4.45 va ɖo sentimeta 5.55. Ele be dɔwɔlawo nalé ŋku ɖe xexlẽdzesi siawo ŋu nyuie. Ele be pɔmpi ɖesiaɖe nasɔ kple nusi asisi la di.

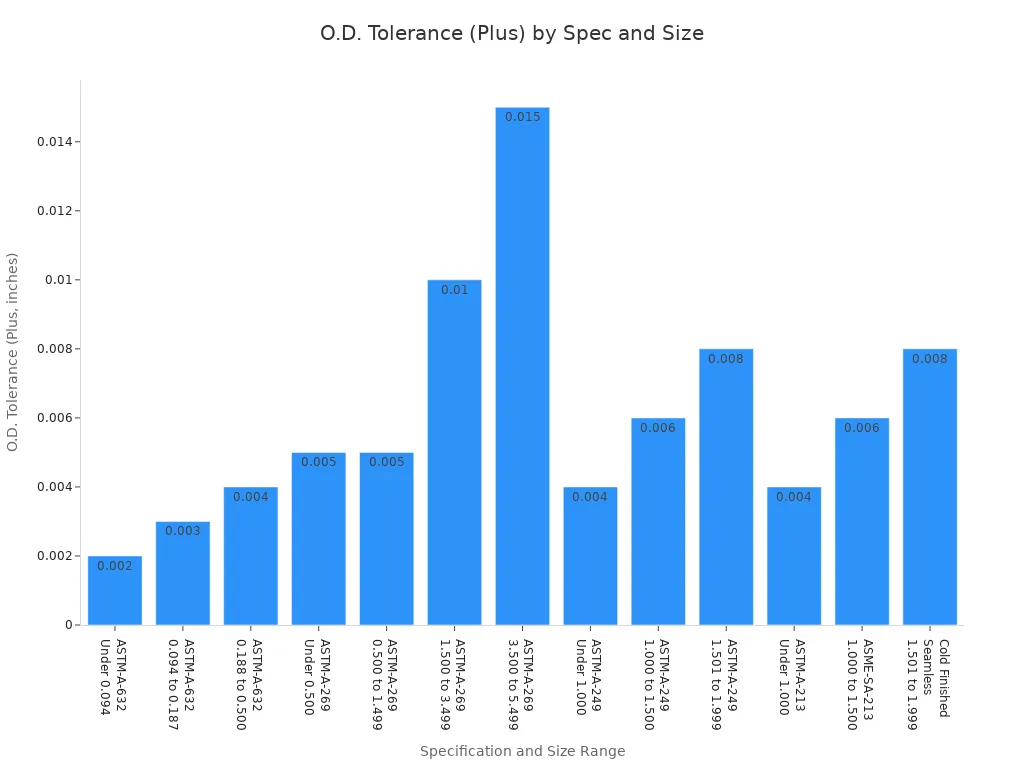

Tabla si le ete la ɖe seɖoƒe siwo bɔ ɖe tube wɔwɔ me fia:

Specification . |

Agbɔsɔsɔme OD ƒe didime (inches) . |

OD ƒe mɔɖeɖe ɖe nu ŋu (plus) . |

OD ƒe mɔɖeɖe ɖe nu ŋu (woɖee le eme) . |

Gli ƒe titrime ƒe mɔɖeɖe ɖe nu ŋu (plus) . |

Gli ƒe titrime ƒe mɔɖeɖe ɖe nu ŋu (woɖee le eme) . |

ASTM-A-632 . |

Le 0.094 ƒe teƒewo la, . |

+0.002' |

0.000' |

+10% . |

-10% . |

ASTM-A-269 . |

le 0.500 ƒe asi me. |

+0.005' |

-0.005' |

+15% . |

-15% . |

ASTM-A-249 . |

le 1.000 ƒe asi me. |

+0.004' |

-0.004' |

+10% . |

-10% . |

ASTM-A-213 . |

le 1.000 ƒe asi me. |

+0.004' |

-0.004' |

+20% . |

0% . |

Vuvɔ si wowu enu seamless . |

1.501 va ɖo 1.999 . |

+0.008' |

-0.008' |

+22% . |

0% . |

Dɔwɔlawo ɖoa sizing mill la nyuie ŋutɔ. Wozãa dɔwɔnuwo abe micrometer kple gauge blocks ene. Dɔwɔnu siawo kpena ɖe ame ŋu wodzidzea afisi agbalẽxatsaxatsa ɖesiaɖe nɔa. Trɔtrɔ ɖe roll gap ŋu kpɔa pɔmpia ƒe lolome dzi. Tɔtrɔ suesuesuewo gɔ̃ hã ate ŋu akpɔ ŋusẽ ɖe pɔmpi ƒe nyonyome dzi.

Nɔnɔme ƒe ɖekawɔwɔ .

Nɔnɔme ƒe ɖekawɔwɔ fia be pɔmpi ɖesiaɖe le goglo eye gɔ̃ hã. Dɔwɔlawo léa ŋku ɖe nu geɖe ŋu be mɔ̃a ƒe nɔnɔme nasɔ. Ele be mɔfialawo ƒe agbalẽ xatsaxatsawo nanɔ sesẽm eye womagbã o. Ʋu siwo wotsɔna ʋuae la hiã lolome si sɔ. Ele be woatsɔ bearingwo ade agba me le mɔ nyuitɔ nu. shafts alo stands siwo wobɔbɔ si menye straight o ate ŋu ahe kuxiwo vɛ.

Tabla si le ete la yɔ nu vevi siwo wòle be nàkpɔ be nɔnɔme nyui le:

Kpɔ nya la ɖa . |

Nuɖᴐɖᴐ |

Mɔfiame Rolls Integrity . |

xea mɔ na strip drifting kple camber. |

Ʋu ƒe ʋuƒo siwo wotsɔna ƒoa ʋu od . |

Eƒoa asa na out-of-roundness kple dimensional ƒe tɔtrɔwo. |

Bearing fefe . |

Enaa shaft ƒe ʋuʋu nɔa edzi yim. |

Shafts siwo wobɔbɔ . |

Dzadzraɖo siwo hiã na mɔ̃ siwo me womeɖea mɔ ɖe nu ŋu le o. |

Megbe abɔta ƒe ɖoɖo . |

Eléa roll alignment me ɖe asi. |

Drive tsi tre ɖe ɖoɖo nu . |

Ekpɔa egbɔ be wole tsia dzi le tsia dzi, le tsia dzi, eye wòle dzogoe ene me. |

Shafts parallelism . |

Enaa shafts nɔa sɔsɔm le nutunuwɔƒea katã. |

Rolls parallelism . |

Kpɔa nu kple go dzɔdzɔewo kple dzidzenuwo dzi. |

Weld Box Assemblies . |

Eléa mɔ̃ɖaŋununya ƒe blibonyenye kple ɖoɖowɔwɔ ɖe ɖoɖo nu me ɖe asi. |

Ironing ƒe mɔzɔzɔwo . |

Checks mawo tɔgbe abe alesi Drive toa ene. |

Dɔwɔlawo zãa sensorwo tsɔ léa ŋku ɖe didime kple gli ƒe titrime ŋu ne wole pɔmpiwo wɔm. Wotrɔa asi le duƒuƒu, nyaƒoɖeamenu, kple dzoxɔxɔ ŋu be pɔmpiwo nanɔ ɖeka. Edziedzi ƒe dodokpɔ kple nuŋlɔɖi nyuiwo kpena ɖe ame ŋu wòkpɔa dɔwɔnu ƒe vuvu eye wòdzudzɔa nɔnɔme ƒe kuxiwo. Ne kuxi aɖe li la, dɔwɔlawo léa ŋku ɖe roll ƒe ɖoɖowɔwɔ, dɔwɔnu ƒe nɔnɔme, kple mɔ̃ ƒe ɖoɖowo ŋu.

Kpekpeɖeŋu: Sizing-nutunua ɖoɖo nyuie eye ŋkuléle ɖe eŋu zi geɖe kpena ɖe ame ŋu be pɔmpi siwo ƒe nɔnɔme kple lolome sɔ ɣesiaɣi la nanɔ anyi. Esia le vevie na dɔwɔƒe siwo hiã pɔmpi siwo sɔ pɛpɛpɛ ŋutɔ.

Fafa kple eɖɔɖɔɖo .

Fafa ƒe akpa .

Fafa ƒe akpaa le vevie ŋutɔ le tube mill dɔwɔwɔ me. Ne wotsɔ ga ƒoe helolo la, pɔmpia dona le dzo me. Fafamɔ̃wo zãa tsi alo fafanu tsɔ fana ɖe pɔmpia me kabakaba eye wowɔa nu ɖe ɖoɖo nu. Fafamɔ̃ nyui aɖe kpena ɖe ame ŋu be wòafa nyuie wu. Tsidzraɖoƒea dada ɖe nutunuwɔƒea gbɔ eye pɔmpi gãwo zazã nana tsi si sina kple nyaƒoɖeamenu sesẽna. Dɔwɔlawo fɔa tsiɖɔɖɔ ƒe tsigoe siwo lolo wu pɔmpia ƒe sisi zi gbɔ zi atɔ̃ ya teti. Agbɔsɔsɔ sia naa ɣeyiɣi si sɔ be dzoxɔxɔ nadzo eye ɖinuwo nate ŋu anɔ anyi.

Coolant ƒe nyonyome le vevie na pɔmpiwo wɔwɔ. Filterwo ɖea nu sesẽwo ɖa, eye ami skimmers nana fafanu la nɔa dzadzɛ. Atikewo kpena ɖe ame ŋu wòɖea nusiwo ƒoa ƒu ɖe fafanu me la ɖa. Dɔwɔlawo nɔa te ɖe nusiwo wohiã dzi tiaa fafanuwo. Ami siwo me wodea tsii la fa miamiamia eye woana pɔmpia nagli gake agblẽ sinima aɖe ɖi. Semisynthetics fa miamiamia nyuie wu eye wònɔa anyi didi wu le tank la me. Nuwo wɔwɔ fa miamiamia nyuie wu, na pɔmpiwo nanɔ dzadzɛ, eye womagblẽ nu boo aɖeke ɖe megbe o. Tank gãwo nana fafanu nɔa anyi aɖabaƒoƒo 10 va ɖo 20, si kpena ɖe dzoxɔxɔ ŋu wòdzona eye wònana fafanu me kɔna. Tiatia siawo kpena ɖe pɔmpia ŋu wòfana nyuie eye eƒe nɔnɔme nɔa anyi.

Kpekpeɖeŋu: Fafa ƒe ɖoɖoa me léle ɖe te kple dɔwɔwɔ nyuie xea mɔ na pɔmpi ƒe kuxiwo.

Tube Dzɔla .

Ne fafa vɔ la, ɖewohĩ bend alo twists suewo anɔ pɔmpia ŋu. Tube dzraɖoƒea ɖɔa akɔta siawo ɖo eye wònana pɔmpia ƒe lolome sɔ. Dzɔla la zãa dies kple roller siwo ƒe nɔnɔme le abe V ene tsɔ léa pɔmpia ɖe te sesĩe. Ta si me tsi le la ƒoa nu kple ŋusẽ si sɔ, si wɔnɛ be pɔmpia trɔna eye wònɔa fli me tẽ. Gantry la ʋãa indenter la yia teƒe kɔkɔa, eye hadrolik-tsilindoa tena ɖe anyi be wòanɔ dzɔdzɔe.

Dɔwɔlawo wɔa esia to pɔmpi bliboa dzi vaseɖe esime wòle dzɔdzɔe ale gbegbe. Woléa ŋku ɖe pɔmpia ŋu le agbagbadzedze ɖesiaɖe megbe. Ne pɔmpia mele dzɔdzɔe o la, wowɔa pass geɖe wu. Fafa le dzraɖoƒe aɖewo si be woana pɔmpia nanɔ dzoxɔxɔ si sɔ me. Esia tɔa te be dzoxɔxɔa natrɔ. Asitɔtrɔ le eŋu nyuie kple ŋkuléle ɖe eŋu ɖɔa kuxi ɖesiaɖe si dona tso welding kple fafa me ɖo, eyata tube la ɖoa se ɖesiaɖe ƒe lolome ƒe sewo gbɔ.

De dzesii: Nyuie . Dzɔdzɔenyenye nana be pɔmpi ɖesiaɖe sɔ na lãɖeɖe, ƒoƒo ɖe wo nɔewo dzi, kple dodokpɔ mamlɛawo.

Lãɖeɖe kple ƒoƒo ɖe wo nɔewo dzi .

Tube lãɖeɖe .

Tutuawo ɖeɖe ɖe didime nyuitɔ nu le vevie ŋutɔ. Egbegbe tube-mɔ̃wo zãa lãɖeɖe ƒe ɖoɖo tɔxɛwo. Nuɖoanyi siawo kpena ɖe tube ɖesiaɖe ŋu be wòawɔ ɖe lolome si tututu hiã dzi. Kɔmpiutawoe kpɔa dɔwɔnu siwo wotsɔ lãa nu la dzi. Esia nana be lãɖeɖe ɖesiaɖe sɔ eye wònɔa nenema ɣesiaɣi. ERW 50 tube mill ate ŋu atso tubes kple vodada sue aɖe ŋutɔ. Eƒe didime nɔa eteƒe ɣesiaɣi kloe, eye vodada sue aɖe koe nye 0.5% le tube ƒe gotagome lolome me. Tube ƒe didime hã te ɖe wo nɔewo ŋu ŋutɔ, eye vovototo si nye milimeta 3 koe woɖe mɔ na. Esia nyo na ʋuwɔlawo kple xɔtulawo.

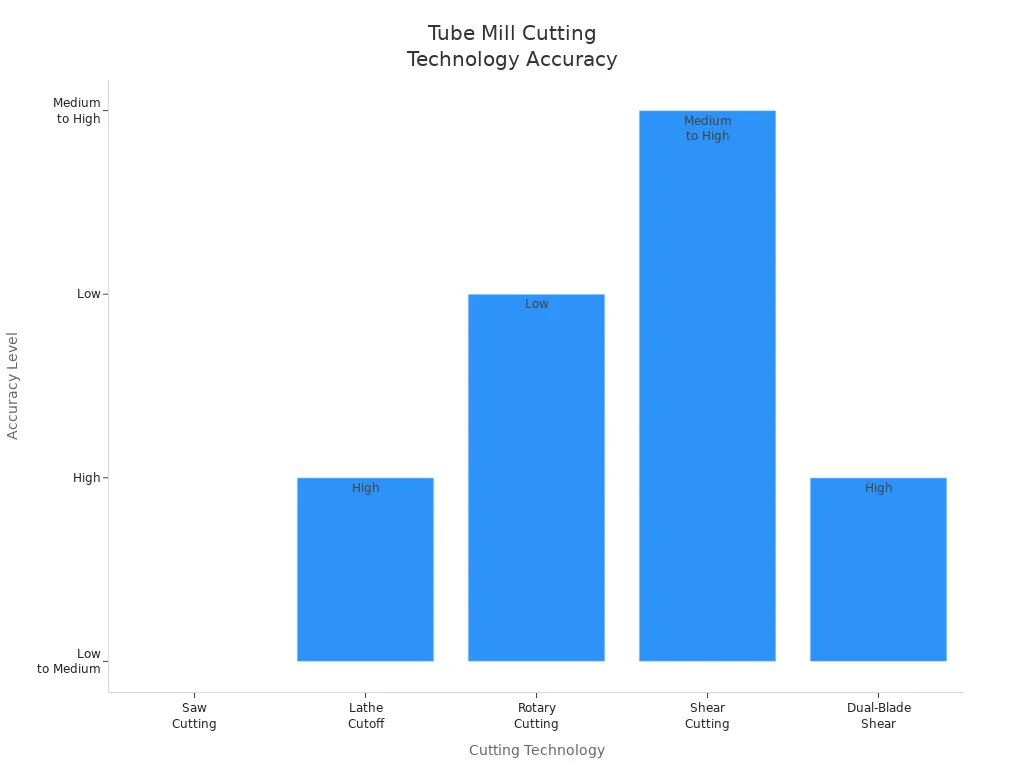

Tube-nutunuwo zãa mɔ vovovo siwo dzi woato atso tube. Saw lãɖeɖe zãa spinning saws alo band saws na tube ƒe lolome geɖe. Lathe cutoff nyo wu na tube siwo le ʋeʋẽm kple lolome gãwo. Enaa lãɖeɖe siwo le dzadzɛ eye wole dzɔdzɔe. Rotary lãɖeɖe wɔa dɔ nyuie na nu fafɛwo. Lãɖeɖe, vevietɔ kple akplɔ eve, zɔna kabakaba eye wòwɔa nuwuƒe siwo le gbadzaa na gakpo siwo mesẽ o ƒe mɔ̃wo. Dual-blade shear lãɖeɖe wɔa dɔ kabakaba ŋutɔ eye wòde pɛpɛpɛ. Ate ŋu awu lãɖeɖe nu le sɛkɛnd ɖeka si mede ɖeka o me. Mɔ̃woe wɔa dɔa ƒe akpa gãtɔ, eyata vodada ʋɛ aɖewo koe li eye nusiwo megblẽna boo o. Esia kpena ɖe dɔwɔƒea ŋu be mɔ̃wo nawɔ dɔ kabakaba wu.

Stacking kple Bundling .

Ne wotsoe vɔ la, mɔ̃awo yia teƒe si woɖoa wo ɖo. Mɔ̃wo kple sensorwo xlẽa nu eye woɖoa wo ɖe fli me. Esia kpena ɖe ame ŋu be woawɔ babla siwo ƒe lolome sɔ. Mɔ̃ siwo me ya alo ami le lae wɔa nusiwo wotsɔ blaa nuawoe. Wotsɔa mɔ̃ goglowo dea dzogoe ade me. Wotsɔa ʋuƒo siwo le dzogoe ene me dea babla siwo le dzogoe ene me. Dɔwɔlawo zãa ka sesẽwo tsɔ léa bablaawo ɖe te. Mɔ̃woe wɔa kaawo sesĩe.

Mɔ̃ siwo wotsɔ ƒoa nuwo nu ƒu ɖe wo nɔewo dzi, abe Fork Arm stackers alo magnetic lifters ene, dea bablaawo ƒe ƒuƒoƒo me. Kɔmpiutawo nana dɔwɔlawo tiaa alesi gbegbe babla ɖesiaɖe loloe eye mɔ̃ agbɔsɔsɔme si yia wo dometɔ ɖesiaɖe me. Woate ŋu atia afisi kaawo yia hã. Esia sɔ kple tube-nutunua ƒe duƒuƒu kabakaba. Mɔ̃wo zazã nana dɔa nɔa dedie wu eye ga menɔa eme o. Woléa ŋku ɖe babla ɖesiaɖe ŋu be woakpɔ egbɔ be enyo. Nu nyui ƒoƒo ƒu kple bablawo dzraa tubeawo ɖo be woaɖo wo ɖe wo. Esia nana mɔ̃awo nɔa dedie vaseɖe esime woɖo asisi la gbɔ.

Quality dziɖuɖu le tube mill dɔwɔwɔ .

In-Process Inspection .

Quality control dzea egɔme esime wole pɔmpiwo wɔm, ke menye le nuwuwu ɖeɖeko o. Dɔwɔlawo zãa dɔwɔnu siwo me wozãa nunya le tsɔ léa ŋku ɖe tube ƒe nyonyome ŋu ne wole dɔ wɔm. Dɔwɔnu siawo kpena ɖe ame ŋu be woake ɖe kuxiwo ŋu kaba eye woana nuwo nanɔ te.

Fotoɖemɔ̃ suesuesuewo léa ŋku ɖe mɔ̃ siwo wotsɔna ƒoa ka na ame ŋu, eye wokpɔa wo le mɔ̃ suewo gɔ̃ hã me. Woɖea foto siwo me kɔ nyuie be yewoakpɔ kuxi suesuesuewo.

Fotoɖemɔ̃ bubuwo léa ŋku ɖe tube gãwo ŋu be wole anyigba kple nɔnɔme ŋuti nyawo me hã.

Laser systems dzidzea ne woɖo goawo kple weld beads ɖe fli me. Esia nana be weld seam la nɔa se sesẽwo me.

Dzoxɔxɔ fotoɖemɔ̃wo kpɔa weld bead kple strip nugbɔ ƒe dzoxɔxɔ. Wokpena ɖe ame ŋu be woaɖu welding dzi eye wodzudzɔa dzoxɔxɔ si gbɔ eme.

Eddy fifia dodokpɔ dia weld kuxiwo to ŋkuléle ɖe elektrikŋusẽ ƒe tɔtrɔwo me.

Metallurgical checks Kpɔ weld la ƒe wɔwɔme sue la ɖa be nàkpɔ egbɔ be esẽ hã.

Dodokpɔ siwo gblẽa nu, abe flattening kple bending ene, check . weld ŋusẽ le kpɔɖeŋu tubes.

Dɔwɔwɔ le wo ɖokui si ƒe nyonyome dzi kpɔkpɔ, si me AI ƒe dodokpɔwo hã le, ɖea vodadawo dzi kpɔtɔna eye wòkpɔa nusiwo gblẽ kabakaba. Nuɖoanyi siawo ɖe asisiwo ƒe nyatoƒoetoto dzi kpɔtɔ 90% eye wogblẽ ga ƒe gazazãwo dzi ɖe edzi 75%. Kpɔkpɔ le ɣeyiɣi ŋutɔŋutɔ me kple nyatakakawo zazã kpena ɖe eŋu be mɔ̃ ɖesiaɖe nasẽ.

Aɖaŋuɖoɖo: Kuxiwo didi kple wo gbɔ kpɔkpɔ kaba kpena ɖe ame ŋu be gakpo siwo ƒe nyonyome nyo ɣesiaɣi la wɔwɔ.

Adzɔnu Mamlɛawo me dzodzro .

Ne wowɔ tubewo vɔ la, wokpɔa wo dometɔ ɖesiaɖe be woawɔ ɖe seawo katã dzi. Dzɔlawo léa ŋku ɖe nu veviwo ŋu:

Agbɔsɔsɔme ƒe dodokpɔwo: gli ƒe titrime, eƒe goglome, kple didime.

Surface checks: Dowo, gbagbãƒewo, alo dzesi bubuwo didi.

Dodokpɔ siwo megblẽa nu o: Eddy current kple ultrasound kpɔa kuxi ɣaɣlawo evɔ womegblẽa nu le tube la ŋu o.

Weld Checks: Dzɔlawo léa ŋku ɖe welding ƒe nyaƒoɖeamenu, ŋusẽkpɔɖeamedzi, ɣeyiɣi, kple fafa ŋu be woakpɔ egbɔ be seams sesẽ.

Dzidzedze: Wotsɔa kpɔɖeŋu siwo wonya be kuxiwo le wo ŋu la léa ŋku ɖe dɔwɔnuwo ŋu.

Mɔ̃ɖaŋununya ƒe dodokpɔwo: Nutunu nyui ɖoɖo kple beléle kpena ɖe toɣliɖeɖe si ɖiɖi le dodokpɔ me tsonu ŋu.

Dukɔ geɖe hiã ɖaseɖigbalẽwo na mɔ̃wo. Tabla si le ete la fia esiwo bɔ:

Ðaseɖigbalẽ Ƒomevi . |

Nuɖᴐɖᴐ |

Zãzã/dɔwɔwɔ si bɔ . |

EN 10204 Ƒomevi 3.1. |

Dzodzro ƒe Ðaseɖigbalẽ si me dodokpɔa me tsonu le si inspector si le eɖokui si si . |

Ami & Gas, Atike, Ŋusẽ, Xɔtuɖaŋu |

EN 10204 Ƒomevi 3.2. |

Ðaseɖigbalẽ si me ame etɔ̃lia ƒe kpeɖodzi le . |

Dɔwɔƒe Siwo Kpɔa Dedienɔnɔ Gbɔ . |

Check siawo kpɔa egbɔ be tube ɖesiaɖe sesẽ eye wòle klalo hafi woaɖoe ɖe wò.

The Tube mill mɔ̃ wɔa tube to afɔɖeɖewo dzi wɔwɔ ɖe ɖoɖo nu. Gbã la, dɔwɔlawo léa ŋku ɖe nu xoxoawo ŋu. Emegbe, wowɔa afɔɖeɖe bubuwo vaseɖe esime woawɔ dodokpɔ mamlɛawo. Afɔɖeɖe ɖesiaɖe kple eƒe kuxi siwo gbɔ wòle be woakpɔ. Kplɔ̃ si le ete la ɖe kuxi vevi aɖewo fia le afɔɖeɖe ɖesiaɖe ŋu:

Fefewɔƒe |

Kuxi vevitɔ . |

Nuwɔna |

Dɔa nutsitsi, akpa siwo womeɖo ɖe fli me o . |

Welding . |

Weld Splits, Bead Kuxiwo . |

Sizing . |

Tube ƒe lolome menye gɔ̃ hã o . |

Dɔwɔnuwo . |

Akpawo ƒe akpa aɖewo le dodom, womeɖo fli ɖe wo nɔewo ŋu o . |

Ne èlé ŋku ɖe nyonyome ŋu le afɔɖeɖe ɖesiaɖe me la, ekpena ɖe tubes ŋu be woanɔ nenema ke eye woɖea gbeɖuɖɔ dzi kpɔtɔna. Mɔ̃ɖaŋununya yeyewo, abe mɔ̃ siwo me wodzroa wo ɖokui kple AI me ene, kpena ɖe eŋu be dɔa wɔwɔ kabakaba eye mɔ̃awo nyona ɖe edzi.

Nyabiasewo ƒe 1999 me.

Nu kawoe ate ŋu awɔ tube mill mɔ̃ ƒe dɔwɔwɔ?

A . Tube Mill Machine wɔa dɔ kple carbon gakpo, gakpo si mexɔ dzo o, galvanized steel, kple alloy aɖewo. Nusi woafɔ la nɔ te ɖe nusi woazã tube la dzi. Dɔwɔlawo tiaa alesi gbegbe wòsẽe, ne etsi tre ɖe gbeɖuɖɔ ŋu, kple nusi seawo nye na dɔ ɖesiaɖe.

Aleke tube-nutunu aɖe kpɔa egbɔ be tube ƒe nyonyome le?

Dɔdzikpɔlawo zãa sensorwo, fotoɖemɔ̃wo, kple ŋkuléleɖenuŋu ƒe ɖoɖo siwo wɔa dɔ ɣesiaɣi. Dɔwɔnu siawo léa ŋku ɖe weld seams, tube ƒe lolome, kple alesi anyigba ƒe nɔnɔme le ŋu. Wodoa kpɔɖeŋuwo kpɔna eye wotrɔa asi le dɔwɔnuwo ŋu zi geɖe be mɔ̃awo nanɔ ɖeka.

Nukae nye alesi wowɔa tube-nutunu ƒe duƒuƒu si bɔ?

Alesi tube-nutunuwɔƒe wɔa dɔe la nɔ te ɖe tube ƒe lolome kple nusi wotsɔ wɔe dzi. Tube-nutunuwɔƒe yeye akpa gãtɔ tsoa meta 30 va ɖo 120 le miniti ɖesiaɖe me. Woate ŋu awɔ mɔ̃ suewo kabakaba wu gãwo.

Ðe mɔ̃memimɔ̃ ate ŋu awɔ tube ƒe nɔnɔme vovovowoa?

Ɛ̃. Tube-nutunuwo ate ŋu awɔ tube siwo le goglo, dzogoe ene me, kple dzogoe ene me tɔ. Dɔwɔlawo trɔa agbalẽ xatsaxatsa ƒe dɔwɔnuwo eye woɖoa nutunua ɖe nɔnɔme kple lolome ɖesiaɖe nu.

Nukatae weld bead ɖeɖeɖa le vevie?

Ne woɖe weld-ku la ɖa la, enana be tube la nɔa blɔ. Afɔɖeɖe sia kpena ɖe tube la ŋu wòdzena nyuie wu eye wòwɔa dɔ nyuie wu. Ekpena ɖe tube la ŋu hã be wòato dɔwɔƒe ƒe se sesẽwo me.