The tube mill machine transforms steel strip into tubes through a detailed production process. Each year, over 28 million metric tons of steel tubes are produced worldwide. These tubes serve industries such as oil and gas, construction, and power plants. The production process begins with inspecting the raw materials, followed by forming, welding, and sizing to ensure every pipe is manufactured to high standards. The tube mill employs specialized machines to shape, weld, and cut the pipes precisely. These tubes have a wide range of applications. Producing quality tubes requires careful attention and continuous monitoring of the production process, helping to meet the global demand for metal pipes.

Key Takeaways

The tube mill machine changes steel strips into tubes. It does this by using steps like checking, shGas & Oilng, welding, sizing, cooling, and cutting. Careful checking of the steel and lining up the edges helps make strong welds. This also helps make good quality tubes. High-frequency welding joins the tube edges fast. It makes strong seams for hard jobs like oil and gas. Sizing mills and straighteners help keep tube shapes and sizes right. This helps meet tough industry rules. Cameras and sensors check the tubes all the time. They find problems early. This makes tubes safer and cuts down on waste.

Raw Material Preparation

Steel Strip Inspection

The tube production starts with checking the raw materials. Workers look at each steel coil closely. They check how it looks and measure its size. They search for problems that might hurt tube quality. Some common problems are:

Cracks that run along or across the surface

Foreign objects pressed into the strip and M-defects

Big breaks, laps, or folds in the strip

Scratches, grooves, and gouges from machines

Strip edges that are damaged or folded

Edges that are rough or cut wrong

Folds in the strip and breaks in the coil

Split edges and tiny holes

Scale pressed in, pits, and marks from rolls

Workers use their eyes and tools to inspect each coil. They make sure the coil is the right thickness and width. Keeping track of each coil is very important. Every coil gets its own special number. The control system saves this information. Mill Test Reports show the steel’s chemical and mechanical details, when it was made, and where it came from. Labels, barcodes, or stamps help follow the coil through the process. This way, every tube can be traced back to its coil. This helps keep things honest and follow the rules.

Accumulation and Feeding

Once checked, the steel strip goes to the next step. The accumulator holds a long piece of strip. This lets the tube line keep working without stopping. The machine makes sure forming and welding always have enough strip. Even when workers change coils, the line keeps moving. Automation here means less work for people and faster production. The control system watches the accumulator and feeder. It changes speed and tension to work best. Moving smoothly from raw steel to the next step helps make good tubes and keeps things running fast.

Uncoiling and Straightening

Uncoiler Operation

The tube production line starts with uncoiling steel strips. A strong uncoiler holds the steel coil and spins it. This lets the strip move to the next step. Operators set the uncoiler’s speed and tension. This helps everything run smoothly. The uncoiler works with different coil sizes and weights. It makes sure there is always enough material. Newer uncoilers use special drives and digital controls. These help change roll positions and keep payout steady. The table below lists common details for uncoiling and straightening machines:

Parameter | Details |

Material thickness capacity | 0.010” to 0.450” (mild steel) |

Material width capacity | 12” to 72” (heavier on request) |

Standard payout speed | 0 to 80 feet per minute |

Features | Variable speed drives, digital roll position indicators, entry/exit support rollers, optimized for HSLA materials |

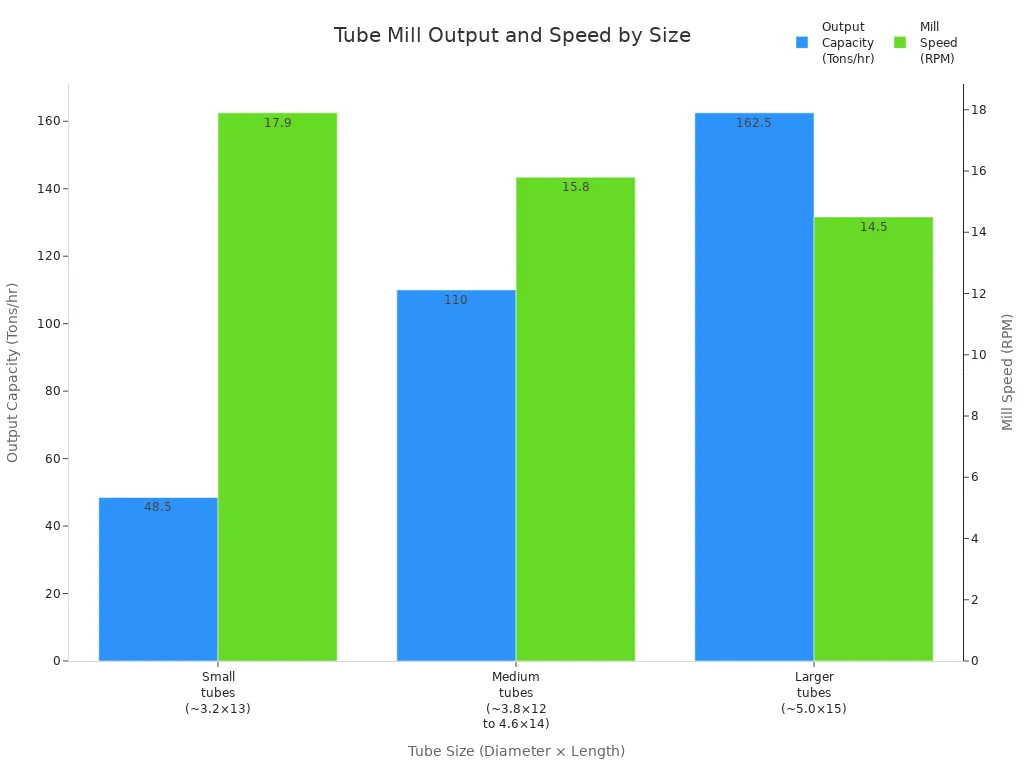

How well the uncoiler works affects the whole line. Fast uncoilers help make more tubes each hour. Output can be from 45 to 170 tons per hour. This depends on the tube size. The chart below shows how output and speed change with tube size:

Strip Straightening

After uncoiling, the strip goes into a straightener. This machine has five to seven rollers. The rollers take out bends and curves from the strip. The straightener sits close to the uncoiler. It pulls the strip right from the coil. Then it feeds the strip into the next step. Some machines combine feeding and straightening. They use strong motors for better speed and accuracy. These machines help keep the strip moving and lined up.

Straightening uses tensile-bending technology. The strip moves through bending, straightening, and tension rolls. The rollers bend the strip in a special way. This fixes shape problems like edge waves and center buckles. The process also removes leftover stress. This makes the strip flat and ready for forming. Good straightening is needed for high-quality tubes. It also helps keep tube sizes correct during production.

Tube Formation Process

Roll Forming

The tube formation process starts when the steel strip goes into the roll forming part of the tube mill machine. The strip changes into a round or shaped pipe by going through several steps. Workers use special machines to make sure each step gives the same results. The roll forming steps in an erw tube mill include:

Uncoiling and Preparation: The steel strip is uncoiled and made flat. This creates a long, flat strip that is ready for forming.

Forming: The flat strip moves through many forming rolls. Each roll bends the strip a little more. This shapes it into a round or custom pipe.

Edge Preparation: Workers clean and get the edges ready. This helps make a smooth weld seam and stops problems in the pipe.

Welding: The erw tube mill uses high-frequency welding to join the edges. This makes a strong seam along the tube.

Sizing and ShGas & Oilng: After welding, the tube goes through sizing rolls. These rolls change the size and shape. They make round, square, or rectangle pipes.

Cooling and Straightening: The new pipe cools down and goes through straightening machines. This takes out any bends or twists.

Cutting and Finishing: The tube is cut into the right lengths. Workers may also do finishing like threading or coating.

Quality Inspection: Each pipe is checked by looking and testing without damage. This makes sure the weld is good and the size is right.

Packaging and Shipping: Finished pipes are bundled, marked, and made ready for delivery.

Tip: Engineers use a "flower pattern" to plan the roll steps. This pattern shows how the strip bends at each stage. It helps make the right tools for the erw tube mill.

The roll forming process needs careful planning. Engineers draw cross-sections, figure out strip width, and design the roll layout. These steps help the pipe meet strict rules.

Edge Alignment

Edge alignment is very important for making good pipes in an erw tube mill. When the strip edges match up, welding makes a strong seam. If the edges do not line up, problems can happen. Bad alignment can cause weak welds or holes. These problems make the pipe weaker.

Modern tube mill machines use special tracking and roll changes to keep edges lined up. Even a small move during welding can change the pipe. Industry rules, like Gas & OilSPEC5L, say the misalignment and burr should not be more than 1.5mm. If it is more, welds can be uneven, cracks can form, and rust can start.

Getting the edges ready, like beveling, also helps the weld. Beveled edges let the weld go deeper and spread stress better. But if bevels are not even or too much is taken off, the pipe can have weak spots. Workers must watch the forming steps, take care of machines, and change settings to keep edges lined up.

Note: Keeping edges lined up in the erw tube mill makes welds better and helps the tube last longer. This is important for tough jobs like oil, gas, and building.

Tube Mill Welding Process

High-Frequency Welding (ERW)

The erw tube mill joins steel strip edges using high-frequency induction welding. This method uses strong electric currents to heat the edges very fast. The edges get hot enough to stick together without adding anything extra. This way is fast and works well, so it is used a lot to make many pipes.

Workers guide the strip through rolls until the edges touch. The high-frequency current heats the edges to the right temperature. Pressure rolls push the hot edges together to make a solid weld. This makes a seam that runs along the whole pipe. The erw tube mill keeps the welds strong and makes many pipes quickly.

There are different ways to weld pipes in factories. The table below shows the main welding methods and how they compare:

Welding Method | Description | Advantages | Limitations | Efficiency Comparison |

TIG Welding (Tungsten Inert Gas) | Uses a tungsten electrode and gas to make neat welds. | Makes clean welds with little mess; works on many materials; good control over heat and weld | Slower speed; needs skilled workers | Slow speed means fewer pipes made; uses more energy because it is slow |

Plasma Welding | Like TIG but uses a hot plasma arc for thick pipes. | Faster speed; deeper welds; good control over heat | Costs more; harder to use | Faster speed makes more pipes; saves energy because it is quick |

High Frequency Welding (HFW) | Uses high-frequency currents to weld pipes fast. | Very fast; makes lots of pipes | Uses more energy because of strong currents | Very fast and good for busy schedules |

Electric Resistance Welding (ERW) | Uses resistance heating to weld pipes. | Accurate and reliable; uses less energy | Uses less energy than HFW | Focuses on saving energy and making good welds |

The erw tube mill works fast and makes many pipes every day. It can make pipes in many sizes and thicknesses. The erw tube mill also keeps the weld seam strong. This is important for pipes used in building, oil, gas, and other tough jobs.

Note: High-frequency induction welding in the erw tube mill makes strong welds quickly. This helps the pipe mill keep running without stopping.

Weld Bead Removal

After welding, the erw tube mill leaves a small bead on the seam. This bead is on both the inside and outside of the pipe. Taking off the weld bead is important for a smooth pipe and good quality. Removing the bead makes the pipe look better and work better.

Workers use scarfing tools with ceramic tips to cut off the outside bead. These tools are on the erw tube mill and cut the bead as the pipe moves. Picking the right tool and keeping it sharp is important. Good tools stop marks and help the pipe match the rest of the material. Bad tools or dull tips can make the pipe rough and wear out fast.

Some factories use robots to grind off the weld bead, especially for big or spiral pipes. These robots move in many ways and use laser sensors to find the bead. The robot grinds the bead down to less than 0.1 mm high and keeps changes under 0.05 mm. This makes the pipe surface very smooth and meets strict rules.

The robots use abrasive belts to grind the bead off fast and keep the pipe nice. This way is common in new tube mills because it is quick and steady. The pipe comes out smooth and ready for the next steps.

Tip: Always removing the weld bead in the erw tube mill helps the pipe look good and work well.

Sizing and ShGas & Oilng

Sizing Mill

The sizing mill is very important in making tubes. Workers use it to set the final pipe size. They adjust the diameter and wall thickness. The mill has many rolls that squeeze the welded pipe. Each roll presses the pipe as it moves forward. This helps the pipe get the right size for its job.

Rules like ASTM A519 tell how close the pipe size must be. Wall thickness can change by about 10% to 12.5%. This depends on the pipe’s size and thickness. For example, a pipe with a 10-inch outer diameter and 2.5-inch wall thickness can have an inner diameter from 4.45 inches to 5.55 inches. Workers must watch these numbers closely. Every pipe must match what the customer wants.

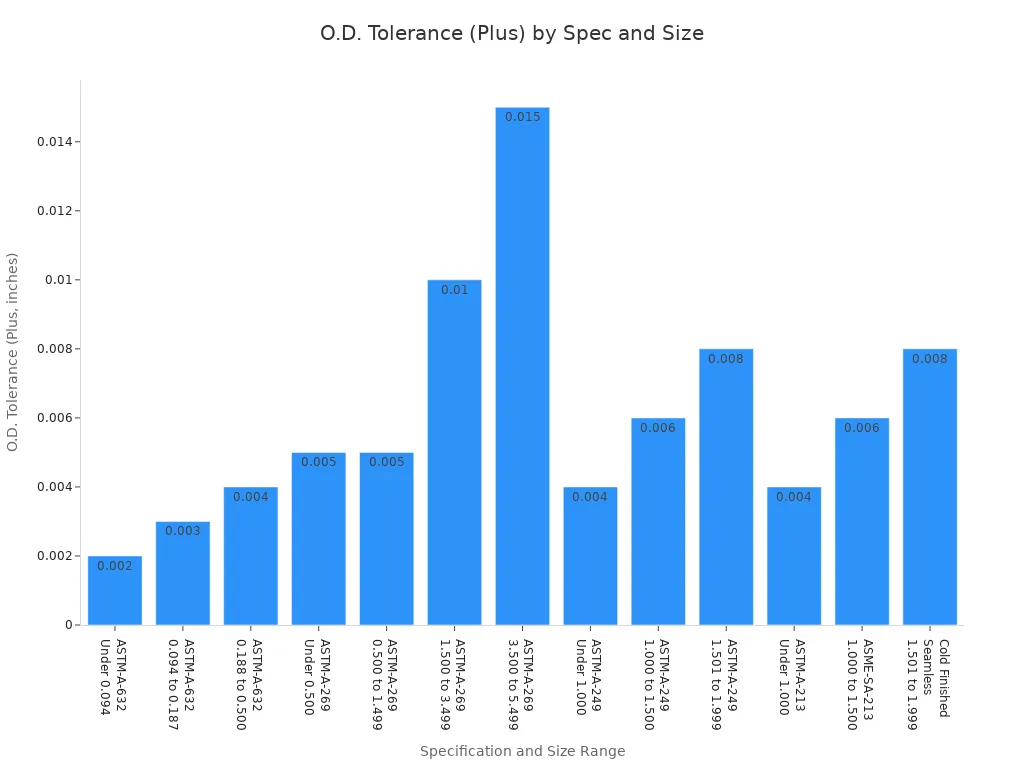

The table below shows common size limits for tube making:

Specification | Size OD Range (inches) | O.D. Tolerance (Plus) | O.D. Tolerance (Minus) | Wall Thickness Tolerance (Plus) | Wall Thickness Tolerance (Minus) |

ASTM-A-632 | Under 0.094 | +0.002" | 0.000" | +10% | -10% |

ASTM-A-269 | Under 0.500 | +0.005" | -0.005" | +15% | -15% |

ASTM-A-249 | Under 1.000 | +0.004" | -0.004" | +10% | -10% |

ASTM-A-213 | Under 1.000 | +0.004" | -0.004" | +20% | 0% |

Cold Finished Seamless | 1.501 to 1.999 | +0.008" | -0.008" | +22% | 0% |

Workers set up the sizing mill very carefully. They use tools like micrometers and gauge blocks. These tools help measure where each roll sits. Changing the roll gap controls the pipe’s size. Even small changes can affect pipe quality.

Shape Consistency

Shape consistency means every pipe is round and even. Workers check many things to keep the tube shape correct. Guide rolls must be tight and not broken. Driven shafts need the right size. Bearings must be loaded the right way. Bent shafts or stands that are not straight can cause problems.

The table below lists key things to check for good shape:

Check Point | Description |

Guide Rolls Integrity | Prevents strip drifting and camber. |

Driven Shafts O.D. | Avoids out-of-roundness and dimensional variations. |

Bearing Play | Keeps shaft movement in control. |

Bent Shafts | Repairs needed for out-of-tolerance shafts. |

Back Shoulder Alignment | Maintains roll alignment. |

Driven Stands Alignment | Ensures horizontal, vertical, and diagonal alignment. |

Shafts Parallelism | Keeps shafts parallel throughout the mill. |

Rolls Parallelism | Checks with straight edges and levels. |

Weld Box Assemblies | Maintains mechanical integrity and alignment. |

Ironing Passes | Similar checks as driven passes. |

Workers use sensors to check diameter and wall thickness as pipes are made. They adjust speed, pressure, and temperature to keep pipes the same. Regular checks and good records help spot tool wear and stop shape problems. If there is a problem, workers check roll alignment, tool condition, and machine settings.

Tip: Setting up the sizing mill carefully and checking often helps make pipes that are always the right shape and size. This is important for industries that need very exact pipes.

Cooling and Straightening

Cooling Section

The cooling section is very important in tube mill work. After welding and sizing, the pipe comes out hot. Cooling systems use water or coolant to cool the pipe fast and evenly. A good coolant system helps cool better. Putting the reservoir near the mill and using big pipes keeps flow and pressure strong. Operators pick flood-type tanks that are at least five times bigger than the pump flow. This size gives enough time for heat to leave and dirt to settle.

Coolant quality is important for making pipes. Filters take out solid bits, and oil skimmers keep the coolant clean. Chemicals help remove things that dissolve in the coolant. Operators pick coolants based on what they need. Soluble oils cool well and make the pipe slippery but leave a film. Semisynthetics cool better and last longer in the tank. Synthetics cool best, keep pipes clean, and leave little behind. Bigger tanks let coolant stay for 10 to 20 minutes, which helps heat leave and keeps coolant clear. These choices help the pipe cool right and keep its shape.

Tip: Keeping the cooling system clean and working well stops pipe problems.

Tube Straightener

After cooling, the pipe might have small bends or twists. The tube straightener fixes these bends and keeps the pipe the right size. The straightener uses V-shaped lower dies and rollers to hold the pipe tight. A hydraulic head pushes with the right force, letting the pipe turn and line up straight. The gantry moves the indenter to the high spot, and the hydraulic cylinder presses down to make it straight.

Operators do this along the whole pipe until it is straight enough. They check the pipe after each try. If the pipe is not straight, they do more passes. Some straighteners have cooling to keep the pipe at the right temperature. This stops bends from heat changes. The careful adjustment and checking fix any problems from welding and cooling, so the tube meets all size rules.

Note: Good straightening makes sure every pipe is ready for cutting, stacking, and final checks.

Cutting and Stacking

Tube Cutting

Cutting the tubes to the right length is very important. Modern tube mill machines use special cutting systems. These systems help every tube meet the exact size needed. Computers control the cutting tools. This makes sure each cut is correct and the same every time. The ERW 50 Tube Mill can cut tubes with a very small error. The diameter is almost always right, with only a tiny mistake of 0.5% of the tube’s outer size. The tube length is also very close, with only a 3 mm difference allowed. This is good for car makers and builders.

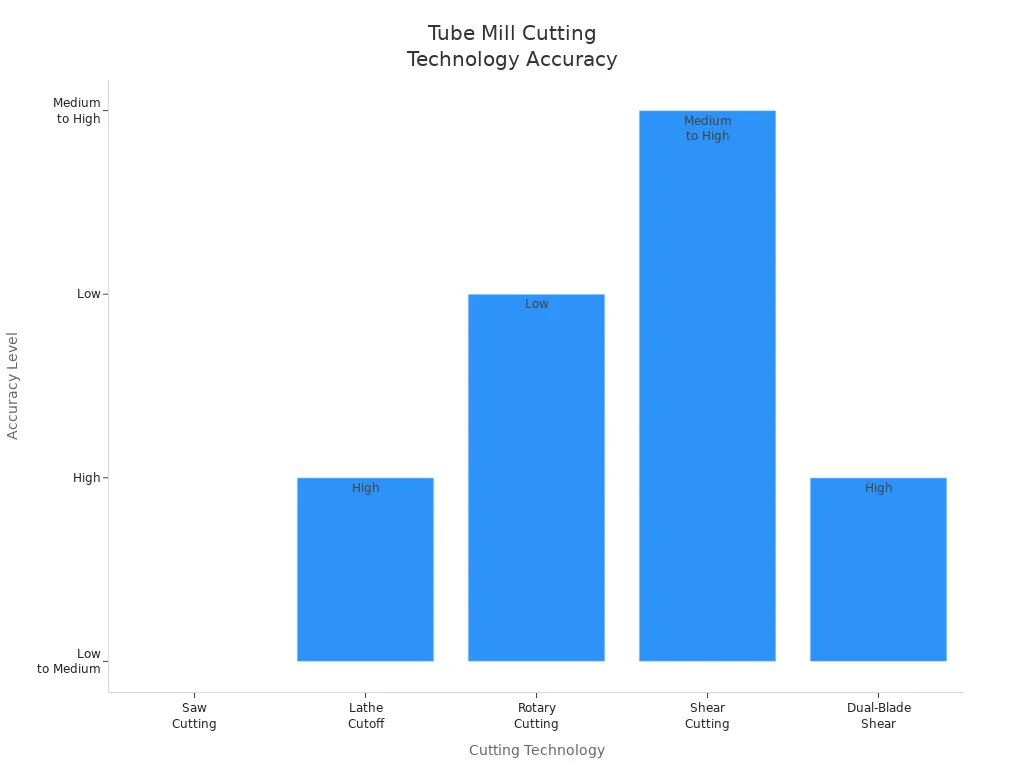

Tube mills use different ways to cut tubes. Saw cutting uses spinning saws or band saws for many tube sizes. Lathe cutoff is best for thick tubes and big sizes. It makes clean and straight cuts. Rotary cutting works well for soft materials. Shear cutting, especially with two blades, is fast and makes smooth ends for mild steel tubes. Dual-blade shear cutting is very quick and exact. It can finish a cut in less than one second. Machines do most of the work, so there are fewer mistakes and less wasted material. This helps the factory make tubes faster.

Stacking and Bundling

After cutting, the tubes go to the stacking area. Machines and sensors count and line up the tubes. This helps make bundles that are the right size. Air or oil-powered machines shape the bundles. Round tubes are put in hexagon shapes. Square tubes are put in square bundles. Workers use strong straps to hold the bundles together. The straps are made tight by machines.

Stacking machines, like fork arm stackers or magnetic lifters, put the bundles in layers. Computers let workers choose how big each bundle is and how many tubes go in each one. They can also pick where the straps go. This matches the fast speed of the tube mill. Using machines makes the work safer and costs less money. Every bundle is checked to make sure it is good. Good stacking and bundling get the tubes ready for shipping. This keeps the tubes safe until they reach the customer.

Quality Control in Tube Mill Process

In-Process Inspection

Quality control starts while making pipes, not just at the end. Operators use smart inspection tools to watch tube quality as they work. These tools help find problems early and keep things steady.

Tiny cameras look inside tubes, even small ones. They take clear pictures to spot small problems.

Other cameras check bigger tubes for surface and shape issues.

Laser systems measure if edges and weld beads are lined up. This keeps the weld seam within tight rules.

Heat cameras watch the weld bead and strip edge temperatures. They help control welding and stop overheating.

Eddy current testing looks for weld problems by checking electrical changes.

Metallurgical checks look at the weld’s tiny structure to make sure it is strong.

Destructive tests, like flattening and bending, check weld strength on sample tubes.

Automated quality control, including AI checks, lowers mistakes and finds defects fast. These systems have cut customer complaints by 90% and scrap costs by 75%. Watching in real time and using data helps keep every tube strong.

Tip: Finding and fixing problems early helps make steel tubes that are always good quality.

Final Product Checks

After making tubes, each one gets checked to meet all rules. Inspectors look at important things:

Size checks: wall thickness, roundness, and length.

Surface checks: looking for holes, cracks, or other marks.

Non-destructive tests: Eddy current and ultrasound find hidden problems without hurting the tube.

Weld checks: Inspectors look at welding pressure, effect, time, and cooling to make sure seams are strong.

Calibration: Tools are checked with samples that have known problems.

Mechanical checks: Good mill setup and care help lower noise in test results.

Many countries need certificates for tubes. The table below shows common ones:

Certificate Type | Description | Typical Use/Application |

EN 10204 Type 3.1 | Inspection certificate with test results by an independent inspector | Oil & gas, chemical, power, construction |

EN 10204 Type 3.2 | Certificate with third-party verification | Safety-critical industries |

These checks make sure every tube is strong and ready before shipping.

The tube mill machine makes tubes by following steps in order. First, workers check the raw materials. Then, they do other steps until the final checks. Each step has its own problems to solve. The table below shows some main problems for each step:

Stage | Main Challenge |

Operation | Stopping work, parts not lined up |

Welding | Weld splits, bead troubles |

Sizing | Tube size not even |

Tooling | Parts wearing out, not lined up |

Checking quality at every step helps keep tubes the same and cuts down on waste. New technology, like machines that inspect by themselves and AI, helps make the process faster and the tubes better.

FAQ

What materials can a tube mill machine process?

A tube mill machine works with carbon steel, stainless steel, galvanized steel, and some alloys. The material picked depends on what the tube will be used for. Operators choose based on how strong it is, if it resists rust, and what the rules are for each job.

How does a tube mill ensure tube quality?

Operators use sensors, cameras, and inspection systems that work all the time. These tools check weld seams, tube size, and how the surface looks. They test samples and adjust tools often to keep the tubes the same.

What is the typical production speed of a tube mill?

How fast a tube mill works depends on tube size and material. Most new tube mills run from 30 to 120 meters each minute. Smaller tubes can be made faster than big ones.

Can a tube mill produce different tube shapes?

Yes. Tube mills can make round, square, and rectangle tubes. Operators change the roll tools and set up the mill for each shape and size.

Why is weld bead removal important?

Taking off the weld bead makes the tube smooth. This step helps the tube look better and work better. It also helps the tube pass tough industry rules.