A tube mill shapes metal strips into strong tubes for many industries. The tube mill machine uses advanced controls and automation to boost production speed and quality.

Today, the global tube mill market is growing quickly, reaching $4.2 billion in 2024 and projected to hit $6.5 billion by 2033.

| Year | Market Size (USD Billion) |

| 2022 | 2.5 |

| 2024 | 4.2 |

| 2033 | 6.5 |

Key Takeaways

A tube mill turns flat metal strips into strong tubes. Automated machines help make tubes faster and better.

The tube mill process has steps like uncoiling, forming, welding, sizing, cutting, and checking quality. These steps help make exact pipes for many industries.

Tube mills make pipes for construction, cars, oil and gas, and HVAC. They help these industries grow with fast, cheap, and earth-friendly ways to make things.

Tube Mill Overview

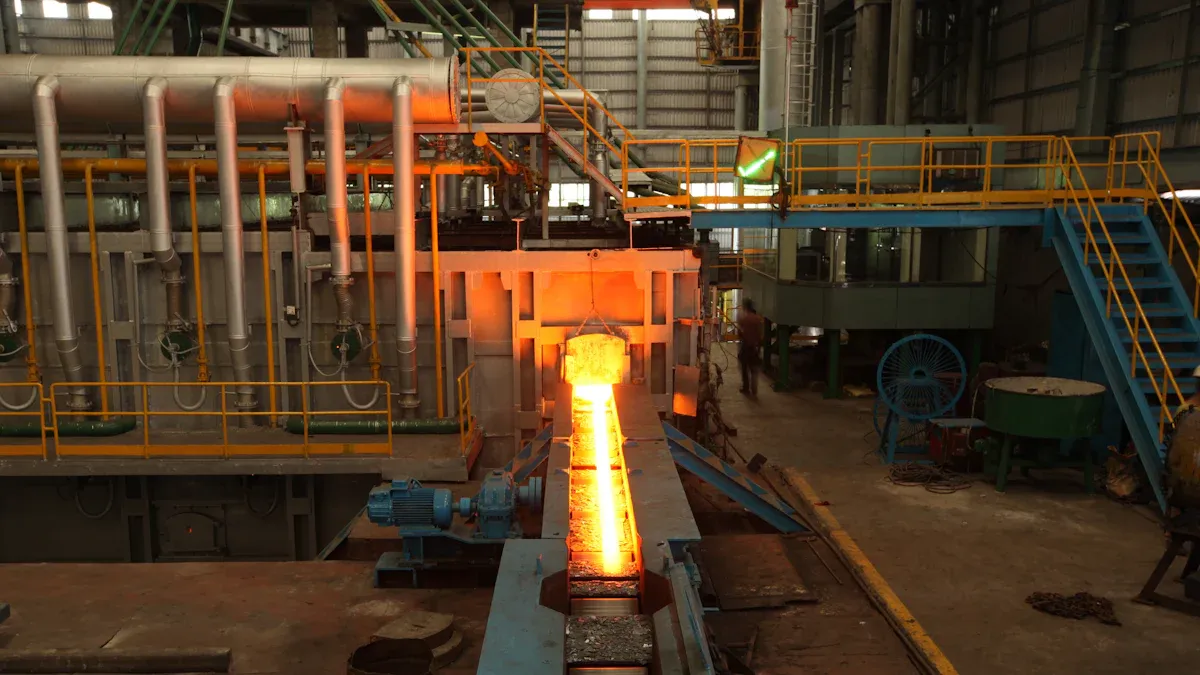

Tube Mill Machine

A tube mill is a special machine used in factories. It changes flat metal strips into pipes that can be round, square, or rectangular. The tube mill machine uses many steps to shape, weld, and size the metal. This makes strong tubes that all look the same. Companies use tube mill machines to make pipes for buildings, cars, and other things.

The tube mill machine starts with a coil of steel or another metal. The decoiler holds the coil and feeds the strip into the machine. The straightener makes the strip flat and smooth. Forming rolls bend the strip into a tube shape. Welding equipment joins the edges to make a solid seam. Sizing rolls make sure the tube is the right size. Cutting machines cut the long tube into shorter pieces. Some tube mill machines have extra stations for finishing and testing to check quality.

Today’s tube mill machines use smart controls and automation. These features help workers watch the process in real time. They can make quick changes and work faster. Automation also means less hard work for people and safer jobs.

Here is a table that lists the main parts of a tube mill machine and what they do:

| Component | Function within the Tube Mill System |

| Decoiler | Holds and feeds the coil of metal strip into the machine, starting the process by giving raw material. |

| Straightener/Flattener | Makes the strip flat and smooth so it is ready for forming. |

| Forming Rolls | Slowly bend the strip into a tube, going from a “U” shape to a closed circle. |

| Welding Equipment | Joins the tube edges using welding methods to make a seam. |

| Sizing Rolls | Make the tube the right size and shape. |

| Cutting Machines | Cut the long tube into set lengths using different saws or cutters. |

| Finishing & Testing | Extra steps like smoothing, threading, or checking the tube for problems. |

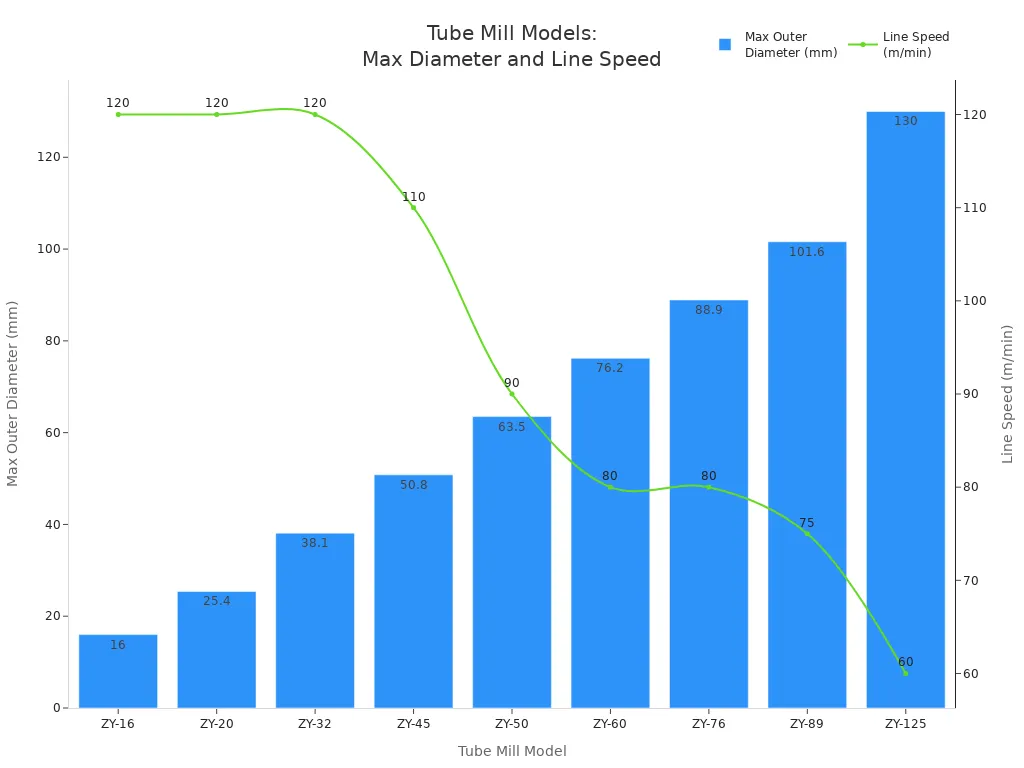

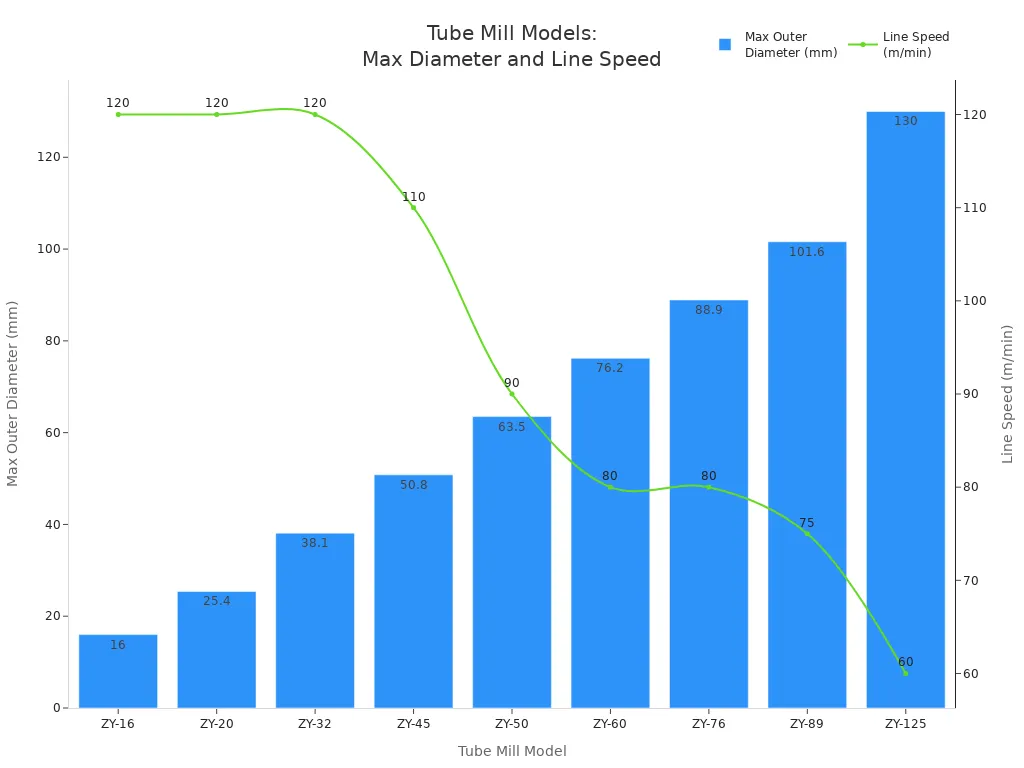

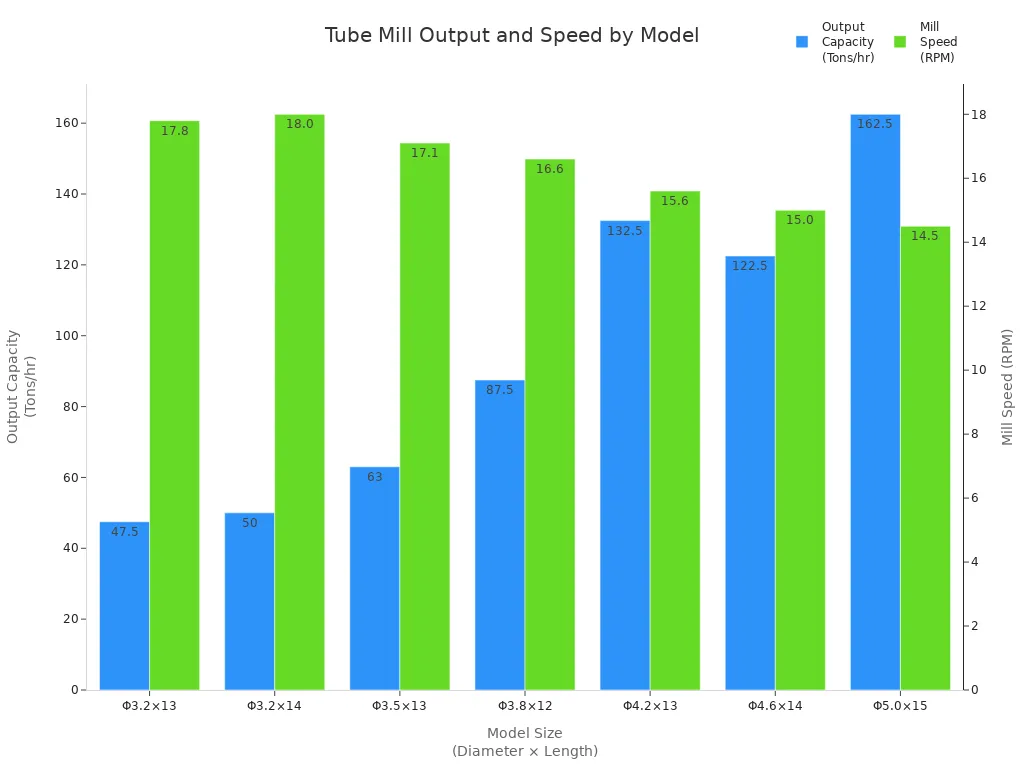

Tube mill machines can work with many metals, like low-carbon steel, stainless steel, and aluminum. They can make tubes in many sizes and thicknesses. This makes them useful for lots of jobs. The chart below shows how tube mill models compare by the biggest tube size and how fast they work:

Main Function

The main job of a tube mill is to make welded pipes from flat metal strips. The tube mill machine shapes, welds, and sizes pipes without stopping. This way, it can make lots of pipes that are all the same size and quality. Tube mills use roll forming, where rolls shape the strip and welding rolls join the edges. This process is fast and accurate, so it is great for making many pipes at once.

Tube mills are different from other machines like press-based systems or ball mills. Tube mills are made for making pipes quickly and all the time. Other machines might work in batches or grind materials, but tube mills are best for making pipes that are all the same. These pipes can be used for building, carrying fluids, or for decoration.

| Aspect | Tube Mill | Other Metal Forming Machines (e.g., Ball Mill) |

| Primary Function | Makes welded pipes from steel strips | Grinds materials into small pieces |

| Operating Principle | Shapes, welds, and sizes pipes nonstop | Crushes or shapes materials in other ways |

| Production Focus | Makes lots of pipes quickly | Often works in batches or uses other methods |

| Precision | Makes sure pipes are the same size and quality | Focus on particle size or shGas & Oilng can be different |

| Application Areas | Used in building, cars, and infrastructure | Used in mining, ceramics, chemicals, or shGas & Oilng |

Tube mill machines have many good points:

They keep the tube wall thick and the shape even.

They make less waste and help the environment.

Automation and controls help work go faster and cost less.

New features like CNC and real-time checks make sure pipes are high quality.

Factories use tube mill machines to make pipes for buildings, cars, heat exchangers, and more. The steel pipe making machine, also called a tube milling machine, is very important in today’s industry. It helps make strong, safe metal pipes very quickly.

Tube Mill Machine Process

The tube mill machine process turns flat steel strips into strong pipes. This process uses special tube rolling machines and automation. These help make many pipes that are all the same quality. The steps below show how a high frequency welded tube mill line works from start to finish.

Uncoiling and Forming

Workers put big steel coils onto the decoiler.

The uncoiler unwinds the coil and feeds a strip into the line.

The steel strip goes through a straightener or leveling machine. This step takes out bends and makes the strip flat.

The flat strip moves through forming rolls. These rolls slowly bend the strip into a round, square, or rectangle shape.

The forming section lines up the edges for welding.

Note: Setting up uncoiling and forming the right way is very important. If the strip edges do not line up, the weld can be weak or the tube can be the wrong size. Coil set and leftover stress can also change the forming step. So, workers must watch the process closely.

Welding

The high-frequency welded pipe machine uses special energy to heat the tube’s edges. This energy makes the edges melt from the inside out. The process uses a high-frequency generator, electrodes, and a pneumatic press. These help make a strong, smooth weld.

| ISO Standard(s) | Focus Area / Quality Requirement Description | Relevance to Welding Stage in Tube Production |

| ISO 3834 series | Quality rules for fusion welding of metals, with different levels | Sets the main quality rules for welding steps |

| ISO 15614-8 | Rules and tests for welding tubes to tube-plate joints | Makes sure welding steps are tested for tube welding |

| ISO 5817 | Quality levels for weld problems in steel and other metals | Sets what weld problems are okay |

| ISO 17662 | Checks and tests for welding equipment | Makes sure welding tools work right |

| ISO 17663 | Quality rules for heat treatment in welding | Covers heat treatment rules for welding |

Sizing and Cutting

After welding, the tube goes to the sizing section. Here, sizing rolls and Turks head units shape the tube and set its size. Workers check the tube at each step to make sure it is right. The welded tube mill line can make round, square, and rectangle pipes with high accuracy.

The cutting machine, often called a flying saw, cuts the tube into set lengths without stopping the line.

Deburring tools take off sharp edges from the cut ends.

Some lines use extra machines for end-facing, chamfering, or surface work.

Sizing and cutting are very important for the tube’s size and surface. Workers must change machine settings and watch the process to stop mistakes and problems.

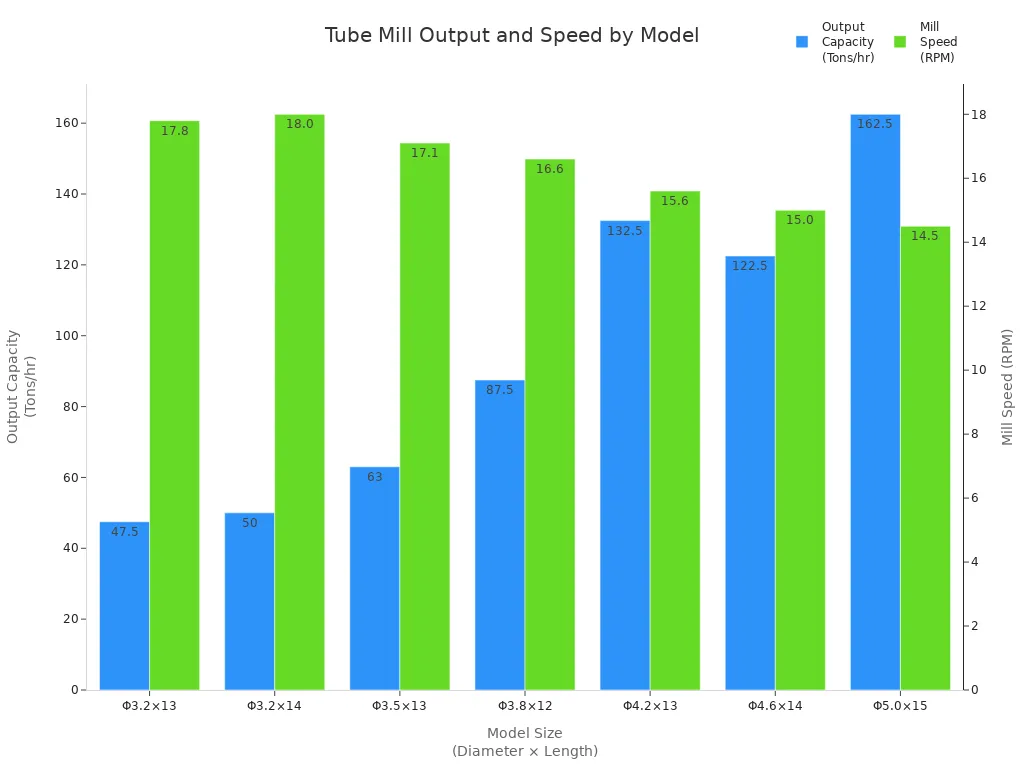

| Model Size (Diameter × Length) | Output Capacity (Tons per Hour) | Mill Speed (Revolutions per Minute) |

| Φ3.2×13 | 45-50 | ~17.8 |

| Φ3.2×14 | 48-52 | ~18.0 |

| Φ3.5×13 | 58-68 | ~17.1 |

| Φ3.8×12 | 80-95 | ~16.6 |

| Φ4.2×13 | 120-145 | ~15.6 |

| Φ4.6×14 | 105-140 | ~15.0 |

| Φ5.0×15 | 155-170 | ~14.5 |

Quality Control

Quality control is very important in the tube mill machine process. Workers use sensors and software to watch production as it happens. Nondestructive tests, like eddy current and ultrasonic checks, find problems without hurting the pipes. Optical sensors check if the tube is straight and round.

Common problems include weld chatter, wrong sizes, splitting, buckling, and marks.

Workers fix these problems by:

Checking and fixing mill parts often.

Fixing or changing worn tools.

Changing roll settings and speeds.

Keeping good records of tools and production.

Training staff to solve problems and do regular care.

Tip: Doing regular care and letting workers help design tools helps stop breakdowns and makes better pipes. Watching the process in real time and using automatic controls in the high-frequency welded pipe machine and pipe welding mill line helps make sure the pipes are always good.

The tube mill machine process, especially in a high-frequency welded tube mill line, helps make pipes for many jobs. The steel pipe making machine and welded tube mill line can make lots of pipes with the right size and a smooth finish. Automation and good quality checks make the process steady and save money.

Types and Applications

Types of Tube Mills

Tube mills come in a few main types. Each type makes pipes in a different way.

Electric Resistance Welding (ERW) tube mills use steel coils. They shape the coils into tubes. Then, they use electric current to weld the seam. These mills work quickly. They make pipes with even walls.

Seamless tube mills use hot steel billets. The billet is pushed or pulled over a mandrel. This makes thick pipes that are short. Seamless pipes cost more. They also take longer to make.

Submerged Arc Welding (SAW) and Double Submerged Arc Welding (DSAW) mills use a welding arc under flux. DSAW mills weld both inside and outside seams. This makes pipes strong for hard jobs.

Specialty mills make pipes in special shapes. For example, rectangular tube mill lines and square tube mill lines make unique pipes.

A stainless steel pipe making machine can use many metals. It can make stainless steel and high strength carbon steel pipes. Each steel pipe making machine is good for certain jobs. It depends on how fast it works, the pipe size, and the material.

Industrial Uses

Steel pipe making machines help many industries. They make pipes for many uses.

Construction companies use pipes for building frames. They also use them for scaffolding and safety rails.

The oil & gas industry needs strong pipes. They use them for drilling, moving oil, and building pipelines.

Car makers use pipes for exhaust systems. They also use them for fuel lines and chassis parts.

Factories use pipes in HVAC systems. They also use them for electrical conduits and water lines.

Service centers and storage places use pipes for racks and shelves.

A pipe mill can also make pipes for homes, fences, and guardrails. These machines help big projects in energy, infrastructure, and factories. The steel pipe making machine works fast and saves money. It makes good pipes and helps industries grow when they need more.

Tube mill machines help make strong tubes for many things we use.

| Industry/Application | Impact on Products and Infrastructure |

| Automotive | Cars have safer, stronger frames and exhaust pipes |

| Furniture | Tables and chairs are tough and look nice |

| HVAC Systems | Pipes work well for heating and cooling |

Tube mill technology keeps changing how we build, travel, and live.

FAQ

What materials can a tube mill process?

A tube mill can process steel, stainless steel, and aluminum. Some models also handle copper or special alloys for different industries.

How does a tube mill ensure pipe quality?

Sensors and cameras check tube size and welds. Workers use tests like ultrasonic or eddy current to find defects before shipping.

Can a tube mill make different tube shapes?

Yes!

Tube mills can make round, square, and rectangular tubes.

Changing the forming rolls allows for different shapes and sizes.