FABEX Saudi Arabia alongside with Metal & Steel Saudi Arabia, since its inception in 2012, has cemented its position as a true address for steel, steel fabrication, foundry, metal processing, forming, cutting, welding, Automation, finishing machinery, equipment, and tools. It provides a genuine business class event for the decision makers, technology giants, industry experts, manufacturers, suppliers, machinery companies, consultants, engineers, agents, traders, distributors, and experts in the steel and metallurgy industry to come together & improve dialogue, trade and domestic & international outreach of the industry in Gulf region.

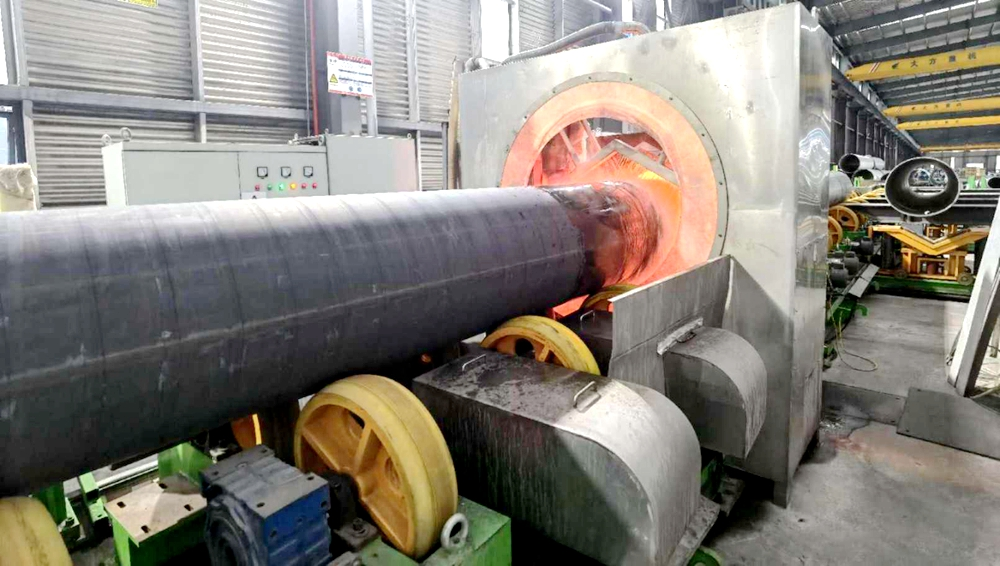

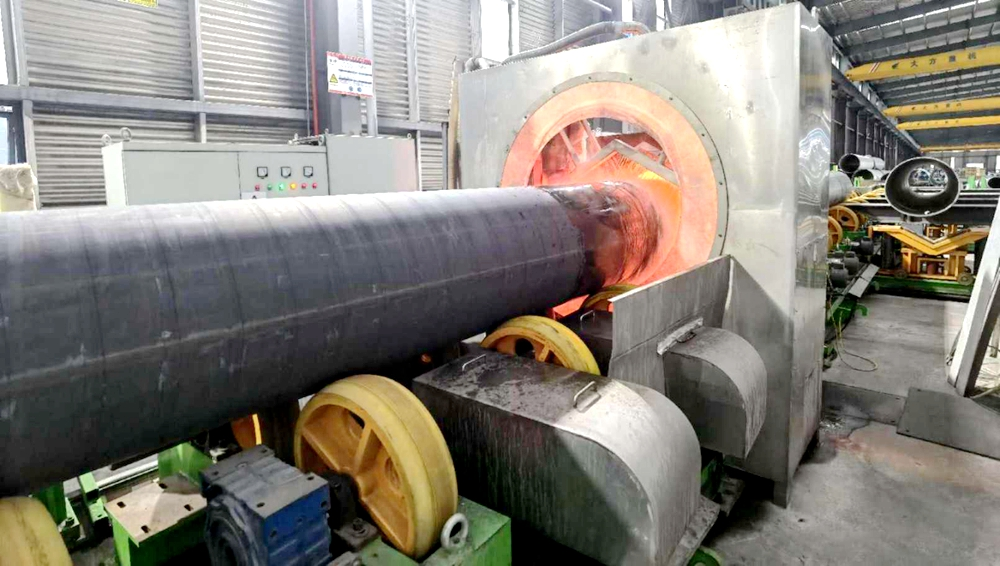

Saudi Arabia has become one of the favorite destinations for the giants. This growing market Arabia is undergoing its most significant period of new steel capacity investment for a decade to capitalize on booming demand driven by Saudi Vision 2030. According to the Saudi Arabia’s Ministry of Industry and Mineral Resources recently, it has secured $6 billion for a steel plate mill complex projects for the shipbuilding, oil and gas, construction and defense sectors and a “green” flat steel complex that will supply the automotive, food packaging, machinery and equipment, and other industrial sectors. Leaning on such a good future development, Hangao Tech (SEKO Machinery) decides to expand our overseas market on this land in next decade. Our offline rotary wheel type induction heating system for gas & oil API steel pipes could totally meet the demand of market's future demands and chance.

Our off-line API steel pipe heat treatment production line has advantages that other similar equipment cannot match.

(1) Air-cooled power supply design: avoids the inconvenience caused by the low ambient temperature of the workshop and the inability to achieve water cooling.

(2) Improve the working environment: reduce the occurrence of safety accidents of steel heating equipment. Workers in the workshop do not need to be exposed to the open flame environment generated by resistance heating, no high temperature will be generated, no other gases or other substances will be generated, and the working environment will be improved.

(3) Multi-channel monitoring: It can control the maximum temperature during heating, ensure product quality, and realize perfect system monitoring and real-time protection.

(4) Using special high-temperature-resistant materials, the maximum temperature can reach 1200 degrees Celsius. The infrared temperature measuring device displays the current temperature of the steel pipe in real time, and the heating uniformity is high.

(5) Human-machine interface PLC automatic intelligent control system coordinates the speed synchronization of the whole line. The intelligent control system is connected with a temperature recorder to record the temperature record of the steel pipe during the entire heating process and automatically generate a heating curve.

The presence of potential buyers from steel, construction, infrastructure, pipelines industries at FABEX Saudi Arabia, led to become FABEX is the solid and reliable platform to establish new links and increase their market share in the GCC.

If you also want to seize the oppoutunity in the future, welcome to visit our Booth M24, Hall 3. on the fair FABEX Saudi Arabia 2023 in Riyadh, from Oct.15-18th, 2023. Looking forward to our meeting!