I. Industry Background and Development Trends

In recent years, the global air conditioning and refrigeration industry has been undergoing a profound material transformation. For decades, copper tubes have been widely used in HVAC systems due to their good thermal conductivity and ease of processing. However, the continuous rise in copper prices and uncertainties in the global supply chain have exposed the risks of heavy reliance on copper. Statistics show that China’s external dependency on copper resources has remained above 70% for many years, while the HVAC industry alone accounts for nearly 15% of total industrial copper consumption annually. This situation not only creates significant cost pressure but also poses challenges for enterprises competing in a highly competitive market.

Against this backdrop, stainless steel tubes are emerging as a strong alternative to copper. Compared with copper, stainless steel offers superior corrosion resistance and a longer service life, significantly enhancing the reliability of air conditioning equipment. In addition, the smoother inner surface of stainless steel tubes reduces refrigerant flow resistance, thereby improving system efficiency. Most importantly, stainless steel costs only a fraction of copper, creating substantial cost-saving potential for manufacturers.

The transition from copper to stainless steel in HVAC applications has already moved from concept validation to pilot adoption, and is now advancing toward large-scale industrial application. This trend represents not only a shift in raw material selection but also an inevitable step toward industrial upgrading and supply chain security.

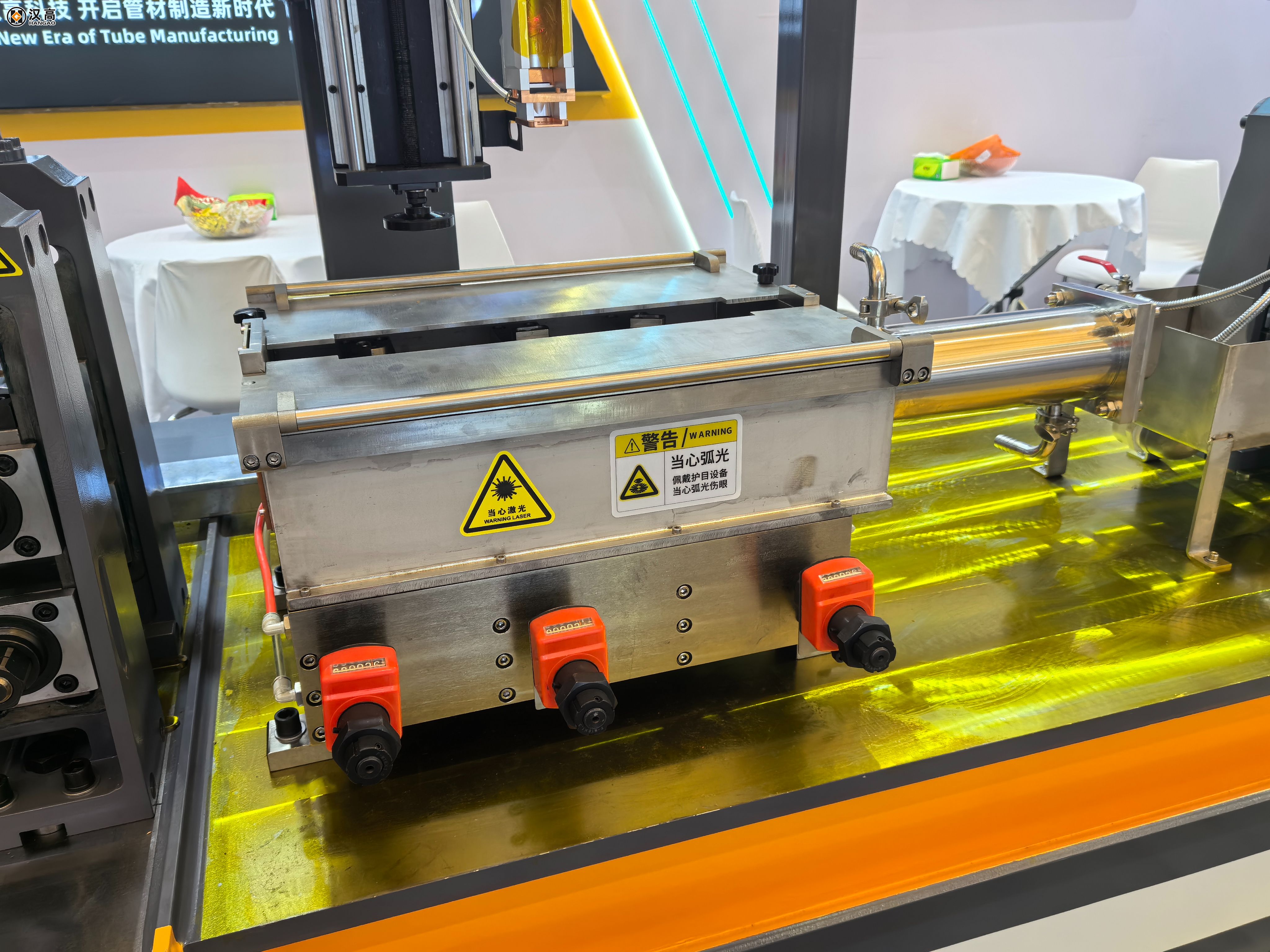

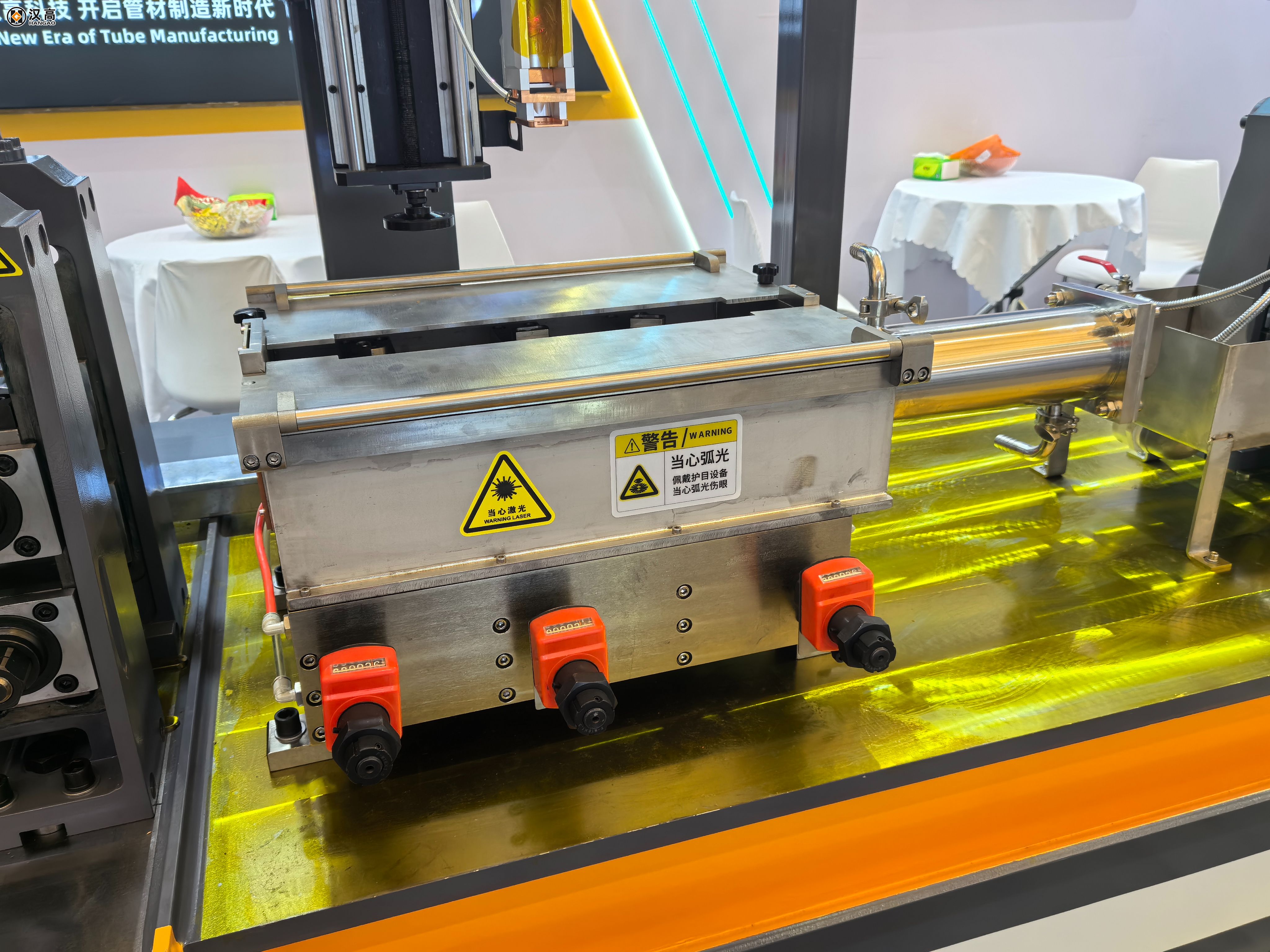

6 Roller Water Cooling Welding Protection Box

II. Advantages of Stainless Steel Tubes in HVAC Applications

Stainless steel demonstrates multi-dimensional advantages in air conditioning systems:

Superior corrosion resistance and longer lifespan

Unlike copper, which corrodes easily in humid or acidic environments, stainless steel resists oxidation and corrosion, reducing maintenance costs and extending service life.

Higher efficiency and system stability

The smooth inner walls of stainless steel tubes minimize refrigerant resistance, lowering energy consumption while improving overall system efficiency.

Significant cost reduction

Stainless steel raw material costs are only a fraction of copper, delivering a clear cost advantage in the highly competitive HVAC industry.

Excellent mechanical properties

Stainless steel offers higher strength and toughness, withstanding greater pressure and impact in diverse application environments.

Green and sustainable

Stainless steel is fully recyclable, aligning with global trends in green manufacturing, carbon reduction, and sustainable development.

These benefits enable stainless steel tubes not only to replace copper but also to bring about a substantial upgrade in performance and cost-effectiveness across the HVAC industry.

HVAC Pipe Rolling & Forming Section

III. Technical Highlights of the Production Line

To fully leverage the benefits of stainless steel in HVAC systems, advanced manufacturing technology and production equipment are essential. Guangdong Hango Technology Co., Ltd. has developed a dedicated stainless steel tube production line for HVAC applications, tailored to replace copper tubes with high efficiency and precision.

1. Wide Material Compatibility

The line is designed for 300-series stainless steel, 400-series stainless steel, 2205 duplex steel, and titanium alloys, meeting diverse requirements in refrigeration, HVAC, and heat exchange applications.

2. Tube Size Range

It supports tube diameters from Φ5–54 mm and wall thicknesses from 0.3–2.0 mm, covering specifications for both residential and commercial HVAC products.

3. Advanced Welding Technology

The system adopts a three-cathode + dual electromagnetic control welding process, ensuring stable weld seams and consistent quality, minimizing defects common in single-cathode welding.

4. High Speed and Intelligent Automation

The production speed reaches 2–15 m/min, significantly faster than traditional equipment. An intelligent control system enables real-time monitoring and automatic adjustment, enhancing efficiency and product consistency.

5. Compliance with International Standards

Products meet standards such as ASTM A312/A312M, A249/A249M, and GB/T 12771-2019, ensuring suitability for global markets and international projects.

IV. Application Scenarios

The use of stainless steel tubes is rapidly expanding across multiple HVAC segments:

Heat exchange tubes: for condensers and evaporators, improving heat transfer efficiency.

Refrigeration tubes: ensuring reliable refrigerant transport with minimal energy loss.

Residential air conditioners: widely used in split AC units, standing units, and small central systems.

Commercial air conditioning systems: applied in office buildings, shopping malls, and hotels.

Central HVAC and industrial refrigeration: providing durability and stability in high-demand environments.

These scenarios highlight the versatility of stainless steel tubes and their growing role as the preferred replacement for copper in modern HVAC systems.

As a leading manufacturer of stainless steel welding and automation equipment, Guangdong Hangao Technology Co., Ltd. focuses on high-end tube production lines. For the HVAC sector, the company has developed a stainless steel air conditioning tube production line with the following advantages:

Customized design: tailored solutions for each client’s specific production needs.

High precision and consistency: ensured by advanced three-cathode welding and electromagnetic control.

Smart automation: real-time defect detection and production monitoring.

Cost efficiency: significantly reducing raw material and production costs while maintaining performance.

Global compliance: products manufactured on the line meet international standards, facilitating global expansion.

Through these capabilities, Guangdong Hangao Technology has become a trusted partner for many HVAC manufacturers seeking material substitution and industrial upgrading.

Welding Protection Box w Water Cooling Design

VI. Future Outlook

The shift from copper to stainless steel is not just a material change but a pathway toward green transformation, intelligent manufacturing, and global competitiveness in the HVAC industry. With fluctuating copper prices and carbon neutrality goals shaping the future, this trend will continue to accelerate.

Key future directions include:

More advanced welding and forming technologies

Adoption of laser welding, automated testing, and precision forming.

Smart manufacturing upgrades

Integration of IoT, big data, and AI for fully digitalized production lines.

Green, low-carbon manufacturing

Lower energy consumption and waste reduction across the production process.

Global market expansion

Stainless steel tubes will continue to expand into international markets, creating new opportunities for collaboration.

Guangdong Hangao Technology will remain committed to innovation-driven development, delivering efficient, intelligent, and sustainable stainless steel tube solutions for global HVAC customers.

Conclusion

In the fiercely competitive HVAC industry, replacing copper with stainless steel tubes has become an inevitable trend. With their superior durability, efficiency, and cost-effectiveness, stainless steel tubes are accelerating the industry’s shift toward a greener, smarter, and more sustainable future. As a pioneer in this field, Guangdong Hangao Technology Co., Ltd. is dedicated to empowering global HVAC manufacturers through advanced stainless steel tube production lines, helping them reduce costs, improve efficiency, and strengthen competitiveness in the new era of air conditioning and refrigeration.