Ungayigcina kanjani umugqa wepayipi wepayipi wepayipi?

Ukubukwa: 759 Umlobi: Isikhathi Sokushicilela i-IRIS: 2024-08-19 Ovela ku-20: Isizango

Buza

Ukuthi iyunithi yomugqa wepayipi we-weldio we-welded engenasici isebenza ngokujwayelekile ihlobene kakhulu nekhwalithi yepayipi eliceliwe elingenamikhawulo. Ukulangazelela kwezingxenye kungenzeka kudale ukubekezelela kwepayipi elingenamikhawulo lensimbi elingenamikhawulo ukuba likhulu kakhulu noma lincane kakhulu, futhi ukubekezelela kokukhiqizwa kwepayipi kwensimbi engenasici nakho kuzokunakwa.

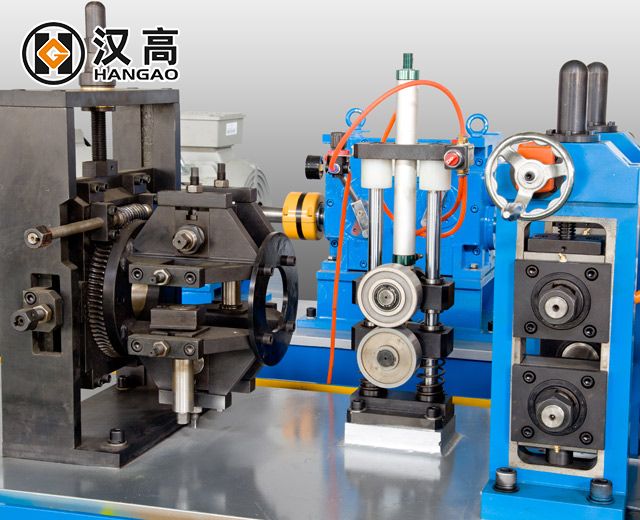

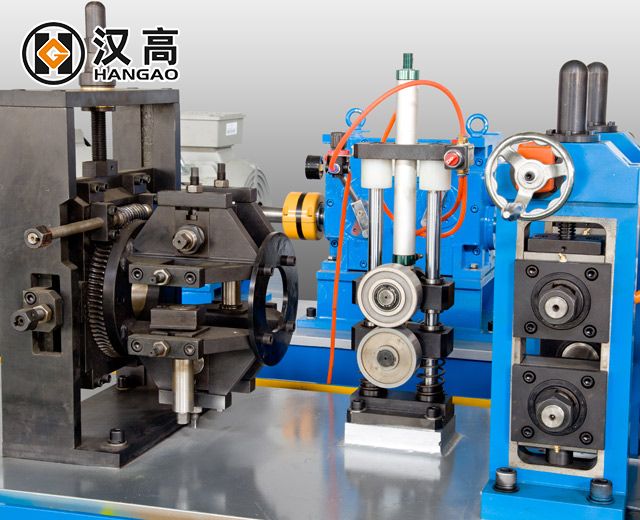

Okulandelayo, I-hangao tech kuzokufundisa ukuthi ungakuqedela kanjani ukulungiswa kwansuku zonke kwe-Unit Work Pidless yensimbi engenasici

Ukugcinwa kwe Umugqa wepayipi wensimbi engagqwali ufaka phakathi izici ezilandelayo:

1. Lubrication of gear izingxenye: gcoba izingxenye zegiya njalo. Okokuqala, ukusebenza okujwayelekile komugqa wokukhiqiza kuhlukaniswe kusuka ekuhanjisweni kwamagiya. Ngakho-ke, kungenzeka ukuthi ukulimala kwegiya kukhulu. Ikakhulu lapho ukwehla noma umsindo kwenzeka, amagiya kufanele agcotshwe ngesikhathi, futhi kufanele kuthathwe izinguquko ezifanele ngokuya ngezimo zokudlidliza zangempela ukuze kuqinisekiswe ukusebenza kwazo okuhle.

2. Ukuhlolwa kwama-slider kanye nojantshi wemihlahlandlela Kuyadingeka ukubheka ukuthambisa kwamalunga namapayipi abo ukuqinisekisa ukusebenza kwawo okuhle.

3. Ukuhlolwa kohlelo lokuthambisa kawoyela we-enjini: Hlola ukunyakaza kwesilinda esizinzile kanye nokujikeleza kwamafutha kanye namalunga ohlelweni lwamafutha enjini ukuqinisekisa ukusebenza kwepayipi kwensimbi engagqwali kanye nekhwalithi yepayipi elinensimbi engenasici.

I-4. Ukuhlanza njalo kwePipe Pipe Pidlo Yezinsimbi Ezingenasici: Kufanele kuhlanzwe ngaphambi kokusetshenziswa. Amanye amapayipi e-weldere angenazinsimbi kufanele futhi ahlanzwe njalo ngaphakathi, futhi izihlungi noma izimbobo zokuhlanza kufanele zibekwe ukuhlanza okulula.

5 Faka esikhundleni noma hlanza isihlungi samafutha ukuze ugcine uhlelo lwe-hydraulic luhlanzekile. Uma isihlungi se-oyili esihle sitholakala sivinjelwe ukungcola, kudinga ukushintshwa ngokuhamba kwesikhathi. Uma isihlungi samafutha ama-coarse sivinjiwe, kufanele ihlanzwe ngesikhathi. Umjikelezo wokuhlola uke waba njalo ezinyangeni ezintathu.

Lapho ekhulisa ithangi, kufanele ihlungwe, bese uwoyela awunakuhlanganiswa namanzi, ukugqwala, ama-chips wensimbi nokungcola kwefayibha.

Ngaphezu kwalokho, lapho uqala ipompo kawoyela ebusika noma ezindaweni ezibandayo, kufanele kuqalwe futhi kuphele amahlandla amaningi ukukhulisa amazinga okushisa kawoyela, bese uqala ukusebenza ngemuva kwesiteshi samaphampu e-hydraulic sisebenza kalula.

Ekugcineni, zonke izinkinobho esiteshini samaphampu e-hydraulic akufanele zithintwe ngabasebenzi abangasebenzi.

I-6

7. Izinyathelo zokuphepha: Ngesikhathi sokukhiqizwa kwamapayipi wensimbi engenasici, kufanele kubhekwe ekuphepheni, ukutholwa kanye namathuluzi okulawula kufanele kusekwe, futhi izinyathelo zokuphepha kufanele zithathwe ngamanye amapayipi abalulekile.

Ngokusebenzisa izinyathelo zokondlo ezingenhla, impilo yenkonzo ye-weldip yepayipi yensimbi engenasici ingathuthukiswa ngempumelelo, ukusebenza kahle kokukhiqizwa kanye nekhwalithi yomkhiqizo kungaqinisekiswa, futhi ukuphepha kwabasebenza kungaqinisekiswa.

Ngamafuphi, ukugcinwa kanye nokugcinwa komugqa wensimbi engenasici kubaluleke kakhulu ukuqinisekisa ukusebenza okujwayelekile kwemishini, kwandise impilo yenkonzo yemishini, ngcono ukukhiqiza, futhi kuqinisekiswe ukusebenza komkhiqizo. Abasebenzi abafanelekayo kufanele banamathisele ukubaluleka emsebenzini wokulungisa, basebenze ngokuya ngezinqubo namazinga, baqinisekise ukusebenza okuhle kwemishini, futhi banikeze ukwesekwa okuqinile kwemisebenzi yentuthuko kanye nemisebenzi yokukhiqiza yebhizinisi.