Recently, a lot of customers come to inspect and ask about the electromagnetic control system is the same thing? Productivity is not efficient enough? Have bite and hump problems improved? Today, I will analyze the function of electromagnetic control system:

At present in the field of industrial stainless steel welding, in order to obtain high quality weld quality. At present, the most mature technology is argon arc welding in automatic welding. When the welding speed increases, the arc is in a free state. The arc will be dragged back along with the forward side of the steel tube (commonly known as the drag arc).

Will cause arc is not firm, penetrability is insufficient. In the weld on both sides of the external and internal sides of the side of the bite problem, the weld inside and outside the "hump" problem. To weld grinding, welding quality has a great impact, especially industrial welding pipe, sanitary pipe. There is a problem of biting edge polishing is not smooth, will cause residual liquid, corrosion of steel pipe. Stress corrosion points can also be caused. Therefore, in the field of industrial welded pipe, in order to obtain high quality welds, the welding speed is reduced to ensure the welding quality.

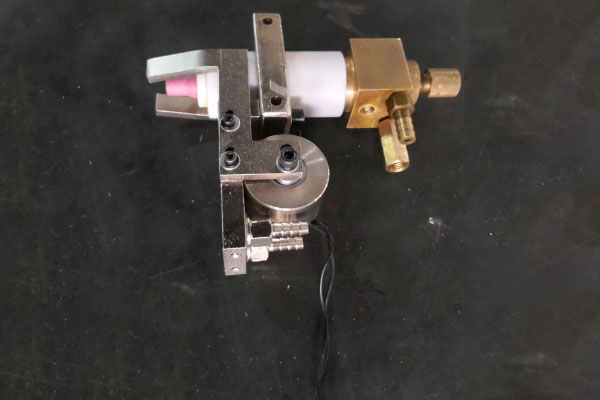

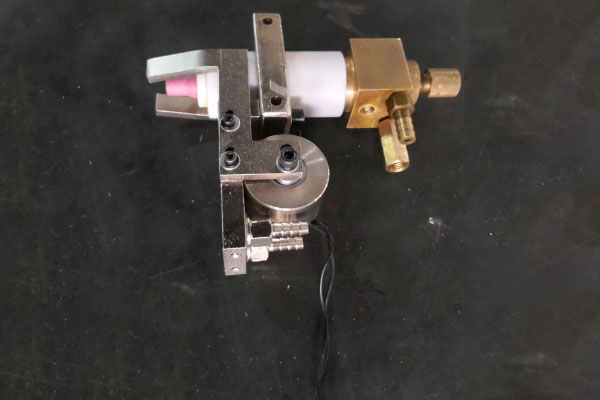

In order to better improve the efficiency of production line, and can get good weld quality, our company research and development of arc welding arc stability, according to the above problem, in the middle of the arc plus can adjust the size of the longitudinal electromagnetic place, through the electromagnetic arc stability in the middle or forward, with electromagnetic stability, arc will not backwards or swinging, bite edge and "hump" problem will not appear. So the production efficiency is improved and the quality is guaranteed. The application of the increased speed in actual production has been verified. In order to adapt to different welding current and production speed, the size of electromagnetic force can be adjusted to adapt to different welding current and speed.

By reflecting the effect of long-term use of the electromagnetic control system by customers, we can improve the production output of customers, bring greater benefits to customers, and solve the problem of biting edge and hump. The customer's reflection diagram is shown in the figure:

The figure above shows that the electromagnetic control system can improve the production efficiency of pipe welding machine and solve the problem of edge chewing and "hump" at the same time after the addition of electromagnetic control welding leveling in oxygen arc welding.

The electromagnetic control system has a great influence. Henkel aims to create value for customers and improve efficiency for customers. Do you want to know more about the equipment of innovative technology? Pick up the phone and call the hotline at 15817831711.