Izinzuzo ze-Three-Cathode Argon ARC WELDING

Ukubukwa: 643 Umbhali: Isikhathi Sokushicilela I-IRIS: 2024-12-05 ORIGID: Isizango

Buza

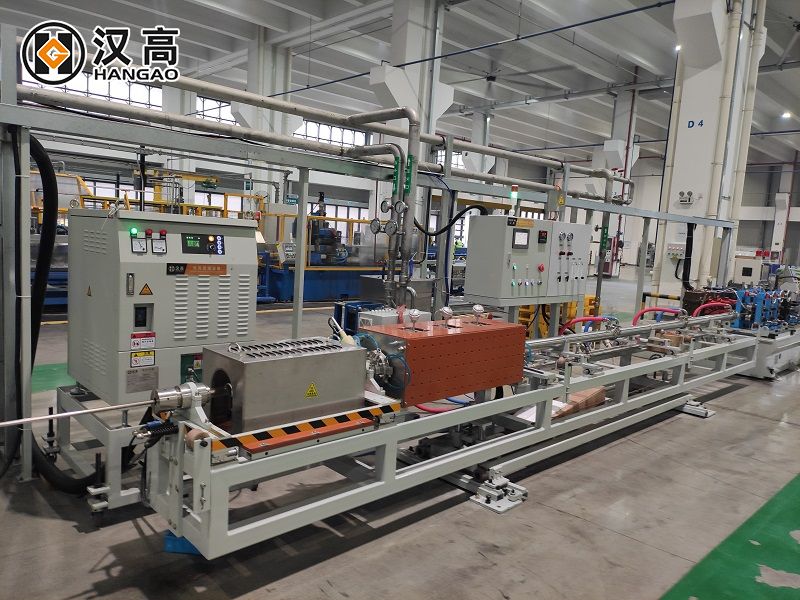

Amapayipi we-welded angenasisekelo asetshenziswa kakhulu futhi asetshenziswa kabanzi ngenxa yezindleko zawo zokukhiqiza eziphakeme zezomnotho kanye nezinzuzo zokusebenza kwamapayipi okuqhathaniswa nalezo zamapayipi ensimbi angenamthungo. Imigqa yokukhiqizwa kwepayipi yensimbi engagqwali nayo iyathandwa ngabakhiqizi bepayipi okwengeziwe ngenxa yokusebenza kwabo okuphezulu, ukusebenza okulula nokuqondayo.

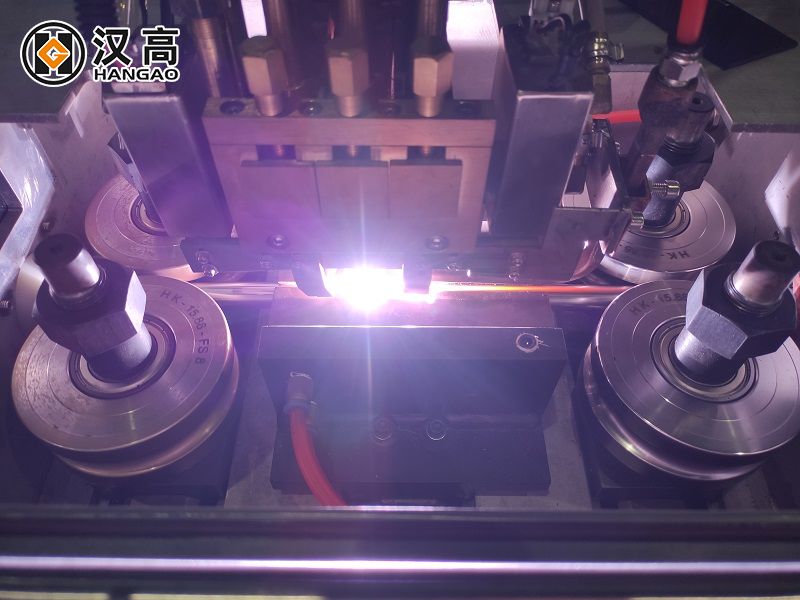

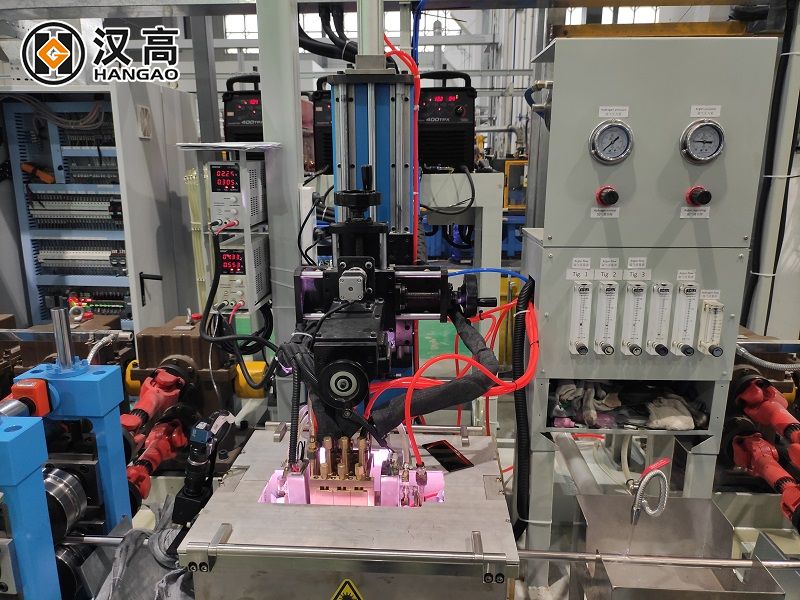

Qhathanisa nemigqa yokukhiqizwa kwamapayipi we-laser welding, yokukhiqizwa kwepayipi ye-Argon arc Imigqa Ukuphela kokulunga ukuthi ijubane lihamba kancane futhi alikwazi ukuhambisana nezidingo zamandla okukhiqiza. Kodwa-ke, ama -argon amathathu we-argon arc arc arc angakuxazulula le nkinga. Lobu buchwepheshe bakhelwe ezinqubweni zokukhiqiza ze-Argon Argc Arc ARC kanye nenani elikhulu ledatha yokukhiqiza, engasiza abakhiqizi ukuthi bakhiqize amapayipi ezimboni ngokunemba ngezidingo eziphakeme kakhulu zekhwalithi ye-weld futhi athole ama-oda aphezulu.

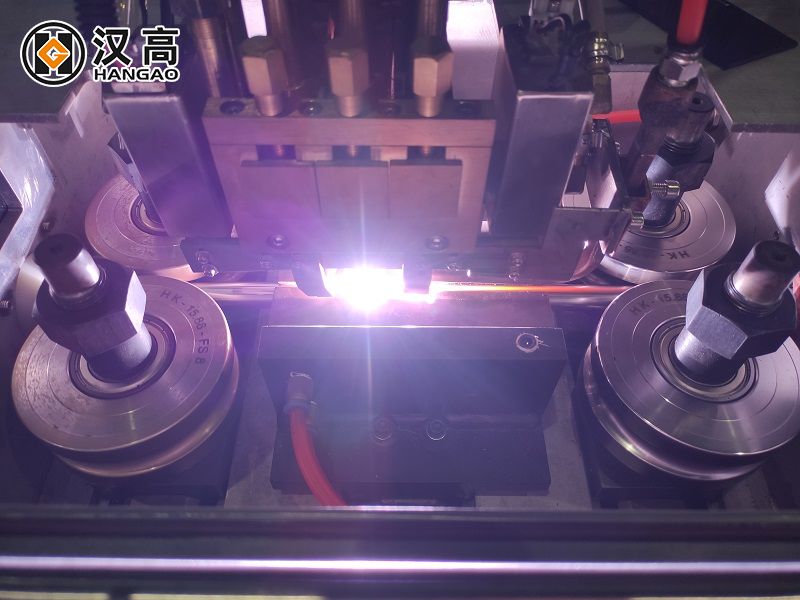

1. Ukuvikelwa kwe-Argon kungahlukanisa imiphumela emibi ye-oksijini, i-nitrogen, i-hydrogen, njll. Emoyeni echibini le-arc ne-molten, yehlisa ukushiswa okuvuthayo kwezinto zololoya, futhi kunciphise amalunga ahlanganayo, angenamsoco aphezulu;

Isifinyezo: Isici esikhulu kunazo zonke se-spatter-mahhala.

2. I-arc ye-argon arc ye-welding ishisa ngokuqinile, ukushisa kugxiliwe, izinga lokushisa lekholomu le-arc liphezulu, indawo ethinta ukushisa iphakeme, futhi izingxenye ezithintekile zinengcindezi encane, izimo zesikhathi, kanye nokuthambekela kokuqhekeka;

Kulula ukusebenza, indawo encane ethinteke ukushisa: Ukusebenza kwe-Argon Arc Welding kuyinto elula, futhi izidingo zamakhono ama-welders ziphansi. Ngasikhathi sinye, ngenxa yendawo yayo encane ethinta ukushisa, indawo yendawo kuphela efudumele ngesikhathi senqubo ye-welding, ehlisa kakhulu umthelela we-thermal ezintweni zokwakha ezizungezile futhi yehlisa amathuba okuguqulwa okushisayo. Ngaphezu kwalokho, igesi ye-argen, njengegesi evikelayo, nayo ingalawula ngempumelelo ukusabela kwe-oxidation ngesikhathi sokufudumala futhi uqhubeke nokwenza ngcono ikhwalithi ye-welding.

Isifinyezo: Isici esikhulu kunazo zonke ukuguqulwa okuncane.

I-3. I-Argon ARC Welding ivuliwe i-arc welding, okulula ukusebenza kuyo nokubona;

I-4. Ukulahleka kwe-electrode kuncane, ubude be-arc kulula ukuligcina, futhi akukho mculi noma ungqimba lwe-flux noma lokuhlanganisa ngesikhathi se-welding, ngakho-ke kulula ukufezekisa ukusebenza kanye ne-automation;

I-5. I-Argon ARC Welding ingavimba cishe zonke izinsimbi, ikakhulukazi ezinye izinsimbi eziwusizo nezinsimbi ezifana kalula, njenge-magnesium, i-aluminium, i-aluminium, i-alloys yazo, ezinokuvumelana okuhle. Lokhu kuguqulwa okubanzi kwenza ukufudumala kwe-argon arcr kusetshenziswe kabanzi emasimini amaningi wezimboni. Noma ngabe kuyinsimbi ephakeme ye-carbon, insimbi engagqwali noma i-aluminium alloy nezinye izinto ezinzima zokulwa ne-welding, i-argon arc welding ingafinyelela i-welding esezingeni eliphakeme.

Isifinyezo: Isici esikhulu kunazo zonke isicelo esibanzi.

I-6. Akukhawulelwe ngesikhundla se-weldentiment futhi kungafakwa kuzo zonke izikhundla.

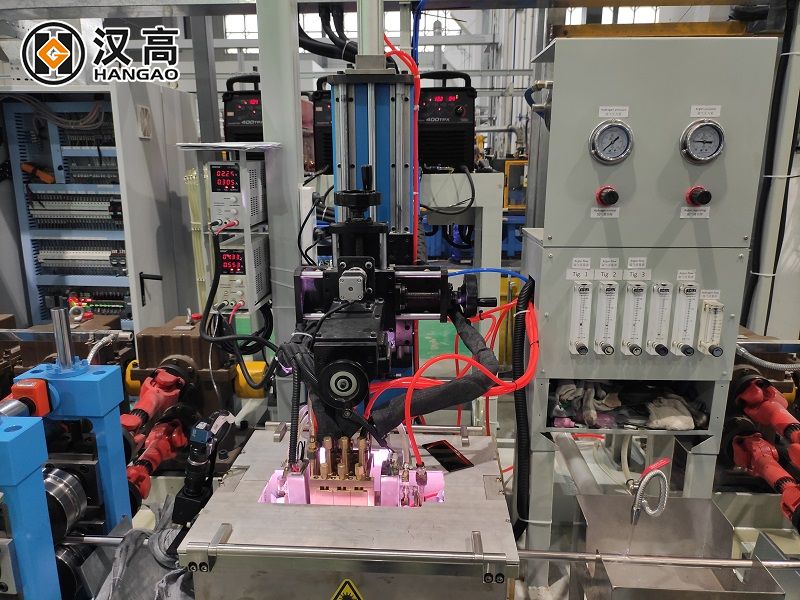

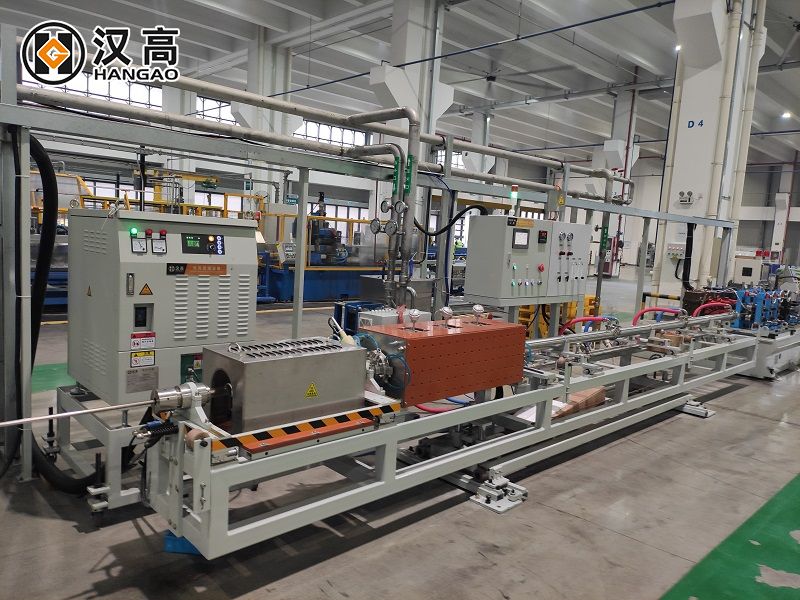

Ngokusho kwempendulo yokukhiqiza esizeni kusuka kumakhasimende, lapho ukucaciswa kwepayipi kungu-15.88 * 0.7mm, umugqa wokukhiqiza usebenzisa isivinini sokukhiqiza i-10m / min, futhi isikhunta ngeke siguqukele. Umugqa wokuphepha we-Henkel uhlome ngohlelo lokuziqhenya lwe-welding lwe-cathode olukhule kanye nokufaka imishini yokushisa okushisa ukushisa ukufezekisa izimpumelelo eziqhubekayo ngejubane lokukhiqiza, elibonwa kakhulu ngamakhasimende.

Uma ukhathazekile nokuthi ijubane lokukhiqiza lamanje alihlangabezani nezidingo ezilindelekile, sicela uxhumane nathi ngemininingwane yezobuchwepheshe eguqukayo yoguquko lwentambo yokukhiqiza!