High-speed tube mill machines help factories work faster and more accurately. These machines use smart computers and sensors to keep things running smoothly. They also use new technology to make sure every product is made well and quickly. Companies save money because they waste less material and need fewer workers. They also spend less on energy. Special welding and fast tool changes make the machines work even better.

Aspect | Impact on Cost and Quality |

Reduction in Workplace Accidents | Makes work safer and lowers costs from injuries |

Productivity Increase | More products made means each one costs less |

Product Consistency | Products look and work the same every time |

Adaptive Wall Thickness Control | Less wasted material saves money |

Real-time Monitoring & AI | Fewer repairs needed, machines run longer |

Quick-Change Tooling Systems | Saves time and cuts down on worker costs |

PLC-Controlled Automation | Less waste and fixing, better product quality |

High-Frequency Welding & NDT | Products are made right the first time, less waste |

Key Takeaways

High-speed tube mill machines help make tubes faster and more exact. They use smart sensors and automation to save money. Advanced welding and real-time checks make tubes strong and even. This means there are fewer mistakes and less waste. These machines work with many materials and tube shapes. Factories can meet different needs quickly. Automation and fast tool changes lower labor costs and waste. They also use less energy and make work safer. Product quality gets better too. High-speed tube mill machines are used in many fields. They help in cars, planes, buildings, and medical tools. These machines help companies grow and stay ahead.

High-Speed Tube Mill Overview

What Are Tube Mill Machines

Tube mill machines are very important in making tubes today. They turn flat metal strips into tubes with different shapes. Some tubes are round, square, or even rectangular. High-speed tube mill machines can work much faster than old ones. They can go up to 600 meters each minute. Older machines only reach about 120 to 180 meters per minute. These machines do many jobs like forming, welding, sizing, and cutting. High-frequency welding helps make strong and smooth joints quickly. Real-time control systems watch and change things like speed and temperature. They also check if the tubes are lined up right. Automated loading and unloading means workers do not have to do as much. This makes the work faster and easier. These machines can make many sizes and types of tubes. Many industries use them because they are flexible. High-speed machines help factories make more tubes in less time. They also keep the tubes the right size and shape every time.

Note: High-speed tube mill machines use smart sensors and PLC controls. This helps every step stay exact and dependable.

Integrated Manufacturing Processes

Integrated manufacturing processes make high-speed tube mill machines special. All the steps work together for better accuracy and speed:

Uncoiling gives a steady flow of steel coil, so the machine never stops.

Forming rolls slowly bend the steel strip to the right tube shape.

Welding, often with high-frequency induction, makes the seams strong and safe.

Sizing and shGas & Oilng rolls fix any mistakes, so tubes are straight and the right size.

Cutting units chop the tubes to the right length.

Finishing steps make the tube surface smooth and nice.

Automation and inline inspection systems check and change settings right away, so tubes stay the right size.

These steps mean factories do not need extra work after making the tubes. Inline systems also use less space and cost less than single machines. Rotary and laser cutting give clean cuts with no rough edges. This makes the tubes look and work better. By putting all these steps together, high-speed tube mill machines help factories work faster and make good tubes every time.

Key Features for Consistent Quality

Advanced Welding Technologies

Tube mill machines use special welding methods for strong seams. High-frequency welding is very important in these machines. This method lets the machine weld fast and keeps seams neat. TIG welding helps join coils automatically, so work does not stop. Laser welding makes seams strong and does not bend the tube much. It is good for jobs that need exact sizes.

High-frequency induction welding makes seams quickly and works fast.

TIG welding joins coils well and keeps work going.

Laser welding keeps most of the material’s strength. It makes seams with almost no mistakes and keeps sizes exact.

Modern tube mill machines have tools that watch the welding as it happens. These tools use fast cameras, lasers, and heat sensors. They find problems like seams not joined right or edges not matching. The machines change settings by themselves to keep welding perfect. This means fewer mistakes and better quality. High-frequency welding with real-time checks and seam heating makes seams strong and without mistakes. These tubes are good for high-pressure jobs. The machines stop big welding problems and make tubes that are always the right size.

Note: Laser welding is best for making things very exact. TIG welding works for jobs that do not need as much strength. High-frequency welding is used most in high-speed tube mill machines.

Automation and PLC Control

Automation and PLC control help tube mill machines make good tubes every time. The whole line works with one PLC system. Workers use a screen to watch and control each step. Digital Twin technology makes a computer copy of the line. It uses live data from the machines. This copy helps fix problems and change things without stopping work.

AI systems look for surface problems right after forming and welding. They are right more than 99.5% of the time.

Sensors send data to AI, which changes speed, welding power, and cooling right away.

These changes keep sizes exact and make products up to 30% more alike.

Automated steps mean people make fewer mistakes. Robots do dangerous jobs, so workers stay safe. Watching and welding by machine means fewer problems and tubes are made the same way each time. Laser tools measure very closely, up to 0.01 mm. This helps keep sizes exact. Automation means less work for people and less waste. Factories can save up to 15% on waste and 30% on worker costs.

Material Versatility

Tube mill machines can use many materials for different jobs. They work with steel, stainless steel, aluminum, copper, titanium, and plastics like PVC and nylon. Special controls and CNC automation help make tubes the right way every time. These machines can make tubes for planes, cars, hospitals, and buildings.

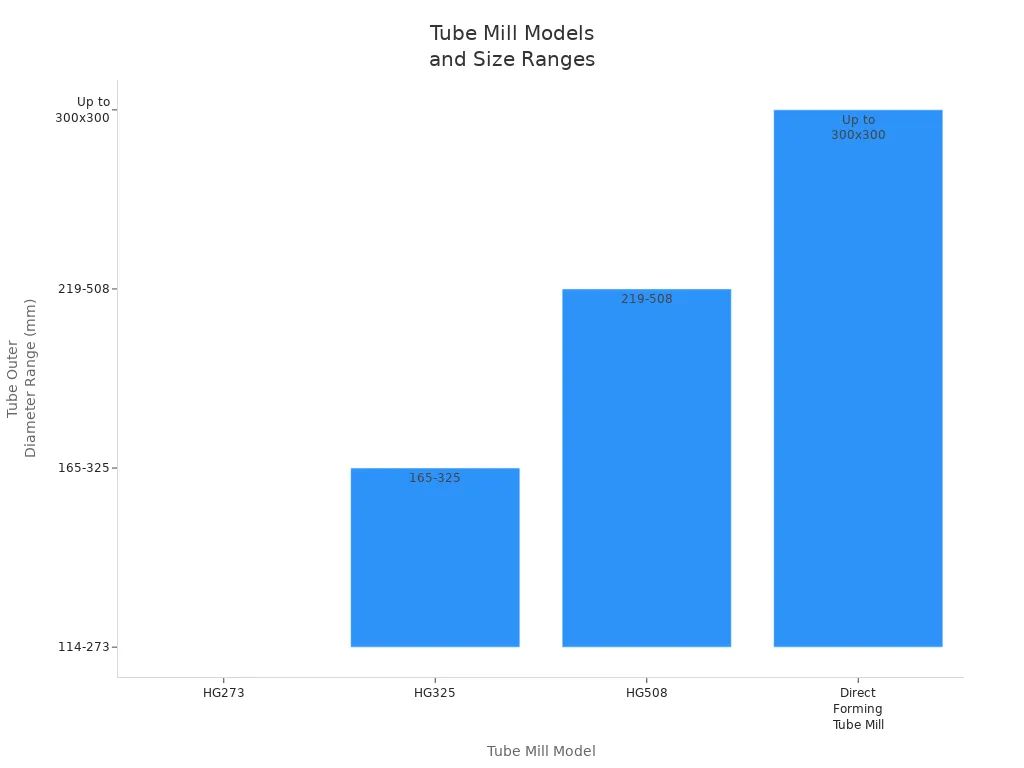

Tube Mill Model | Tube Outer Diameter Range (mm) | Key Features and Applications |

HG273 | 114 - 273 | Makes tubes fast and exact; handles both seamless and welded tubes; automatic loading; used in building, cars, and power plants |

HG325 | 165 - 325 | Makes medium tubes quickly and exactly |

HG508 | 219 - 508 | Makes big tubes with the same controls and automation |

Direct Forming Tube Mill | Up to 300 x 300 (square) | Makes big square tubes directly, so more shapes are possible |

These machines make tubes in many shapes, like round, square, and custom ones. They keep sizes exact and quality high, no matter the material or size. Factories can change tube sizes and materials quickly. This helps them meet new needs fast.

Tube mill machines follow world rules like ASTM, BS, and IS. Their smart controls make sure every tube is the right size and quality. This helps factories sell to many industries and stay ahead of others.

Faster Production Cycles and Efficiency

High Speed Tube Mill Performance

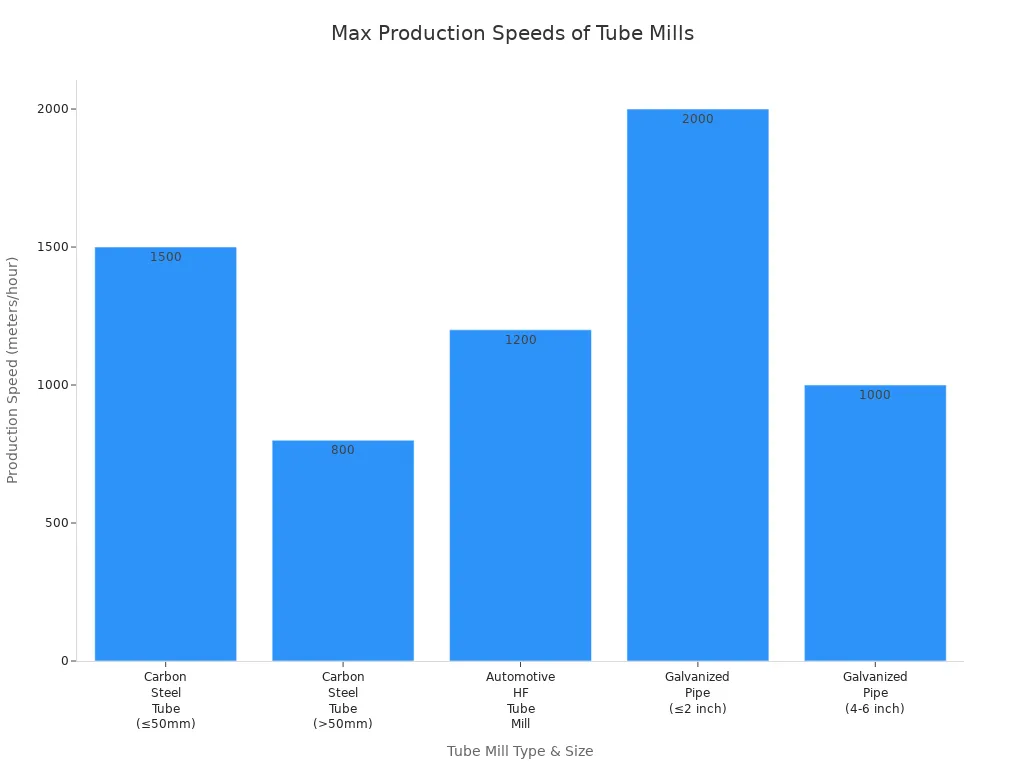

Tube mill machines work very fast and make many tubes. Some new machines can make up to 2000 meters of small pipes in one hour. Even with bigger tubes, they keep going at 500 to 1200 meters per hour. The table below shows how different machines work in different situations:

Tube Mill Type | Tube Diameter Range | Production Speed (meters/hour) | Notes on Throughput and Conditions |

Carbon Steel Round Tube Making Machine | 10mm to 150mm | 800 - 1500 (≤50mm diameter) | Bigger tubes slow down to 500 - 800 m/h |

Automotive High-Frequency Tube Mill | N/A | 600 - 1200 | Makes tubes that are very exact |

Galvanized Steel Pipe Production Line | 1/2 inch to 2 inch | Up to 2000 | Small pipes go fastest; big pipes (4-6 inch) are slower (500-1000 m/h) |

Smart computers and digital twins help these machines work better. Quick-roll change systems let workers switch tools in half the time. Laser-guided alignment and high-frequency welding make the work even faster. These features help factories make more tubes quickly and keep the quality good.

Reduced Scrap and Cost Savings

Tube mill machines use almost all the material and waste very little. Automated welding and cutting systems lower scrap from 8% to less than 2%. Scrap from tube length is now under 0.1%. Quick-change tools and real-time checks cut setup scrap by over 70%. Smart welding systems stop most weld mistakes. These changes help factories use 98% of their material. Companies spend less on raw materials and do not need as many workers to fix mistakes. One company in Southeast Asia made less scrap and changed tools faster after getting new machines. A company in the Middle East saved over $300,000 each year by making less scrap. These examples show how tube mill machines help save money and make more profit.

Energy and Operational Efficiency

High speed tube mill machines use special welders that save energy. These welders work at over 85% efficiency. Closed water-cooling systems use less water and power. Motors and drives use little energy when not working. These things help lower energy bills and repair costs. Automated lines work well and get high scores for being effective. Predictive maintenance uses real-time data to fix machines only when needed. This means less downtime and lower labor costs. Unplanned stops drop by over 90% with real-time checks. Automation and steady work help save energy and protect the environment. These machines make less dust and noise than old ones, so they are better for people and the planet.

Tip: Check and adjust machines often with lasers to keep them working well and making good tubes.

Applications Across Industries

Automotive and Aerospace

High-speed tube mill machines are very important in car and airplane making. These machines help make steel pipes, fuel lines, and other important parts. The parts must be strong and work well under high pressure. This keeps cars and planes safe and working right. Making exhaust systems and fuel lines needs careful work and good checks. The machines can be changed to fit what each industry needs. They can also make tubes in many shapes, like round, oval, or special shapes.

Airplane makers need every part to be just right. Special forming methods and quality rules, like ISO 9001:2015 and AS9100:D, help meet these needs. Fast tool changes and flexible forming let the machines switch jobs quickly.

Performance Requirement Aspect | Solution Provided |

Fast and flexible tooling changes | Quick changeover systems reduce downtime |

High precision and quality forming | Advanced forming technologies ensure accuracy |

Flexibility for diverse needs | Configurable machines for various applications |

Construction and Infrastructure

Building projects use high-speed tube mill machines for strong and low-cost pipes. These machines make welded steel pipes for building frames, scaffolding, plumbing, HVAC, and wires. The pipes are strong, do not rust easily, and can be used in many ways.

Frames and scaffolding for buildings

Pipes for plumbing, HVAC, and wires

Fences, guardrails, and utility pipes

Automation and high-frequency welding make work faster and better. The machines help builders use new designs and build in ways that are better for the planet.

Other Industrial Uses

Many businesses use high-speed tube mill machines for different jobs. Heavy machines, oil and gas, mining, and storage all need strong tubes. The machines also help make things for sports, gyms, and hospitals.

Industrial Sector | Examples of Applications |

Heavy Machinery | Frames for presses, conveyors, crushers |

Oil & Gas | Pipelines for high pressure and corrosive substances |

Mining | Tubes for excavators, drill rigs, haul trucks |

Industrial Storage | Heavy-duty racks and shelving systems |

Hydraulic & Pneumatic Systems | Tubes for high-pressure fluids and gases |

Agricultural Equipment | Tubes for tractors, combines, plows |

Recreation & Fitness | Gym equipment, playgrounds, sports equipment |

Medical Equipment | Precision tubes for catheters, stents, surgical tools |

The machines can make special tube shapes for furniture and medical tools. Automated work and custom options help meet strict rules, so many industries can use these machines.

High-speed tube mill machines help factories work better. Companies pay less for workers and waste less material. The products they make are higher quality. The table below shows these good changes:

Benefit Category | Statistic/Example | Impact/Outcome |

Labor Cost Reduction | 1 operator/shift reassigned | Major savings, higher productivity |

Material Savings | Tolerances ≤ ±0.05 mm | Scrap down 3 points, ~5% margin increase |

Energy Efficiency | Lower kWh per ton | Reduced utility bills |

Production Capacity | 10 to 15 tons/day (50% increase) | 30%+ revenue growth in first year |

Quality Improvement | Defects down by 90% | Consistent, premium products |

Financial Metrics | IRR 22%-25%; break-even in 12 months | Fast, strong ROI |

Automation Benefits | Real-time monitoring | Proactive maintenance, better efficiency |

Market Expansion | New tube types for new clients | Access to higher-margin markets |

Experts say automation, AI, and green ideas will change factories. Companies using these machines get ahead of others. They also help the planet and grow in a smart way.

FAQ

What materials can high-speed tube mill machines process?

High-speed tube mill machines can work with many materials. They handle carbon steel, stainless steel, aluminum, copper, and some plastics. The machines change their settings for each material. This helps keep the quality high.

How do these machines improve product quality?

Automated controls help every tube stay the same size and shape. Real-time monitoring checks for mistakes right away. Special welding and inspection tools find problems early. This means there are fewer defects and better products.

Are high-speed tube mill machines energy efficient?

Yes. These machines use motors that save energy. Smart cooling systems help use less power. Automated lines make less waste and have less downtime. Factories pay lower energy bills and help the environment.

Can one machine make different tube sizes?

Yes. Quick-change tooling lets workers switch tube sizes fast. The machine changes its settings for each new size. This makes it easy for factories to meet new customer needs.

What industries use high-speed tube mill machines?

Many industries use these machines. They are used in automotive, aerospace, construction, oil and gas, and medical equipment. Each industry likes the speed, accuracy, and dependability these machines give.