You see flat metal strips or coils go into tube and pipe mills. You watch them change into strong tubes and pipes. The process uses roll forming and welding to shape the metal. You control how fast it goes and how wide it is. This helps get the right size and quality. Modern mills, like high-speed OTO tube mills, can go up to 900 feet per minute. This makes them very good for making lots of tubes and pipes.

Key Takeaways

Tube and pipe mills change flat metal strips into tubes and pipes. They use roll forming and welding to do this.

Picking the right material is very important. Materials like high carbon steel or aluminum help make strong tubes and pipes.

Welding methods such as TIG and ERW make strong seams in pipes. These seams help the pipes last longer and work well.

Sizing makes sure each tube or pipe has the right diameter and wall thickness. This is important for how the tubes and pipes will be used.

Knowing the difference between seamless and welded pipes helps you choose the best one. You can balance how well it works and how much it costs.

Tube And Pipe Mill Process

Material Input

You pick the right material before you start. Some common choices are:

High carbon, high chrome steel is tough and resists wear.

High-speed steel works well in hot places.

H13 steel is good for hot jobs and is strong.

Carbide with 6% cobalt is used for sizing rolls that need to be very hard.

Nylon is used for shGas & Oilng soft metals like aluminum.

You put flat metal strips or coils into the pipe mill. The metal moves at a set speed. This helps you control the size and quality.

Pipe Mill Forming

You guide the metal strip into the forming part. Roller die tools on top and bottom shape the strip. The rolls bend the metal until the edges touch. This makes the metal stronger. You get tubes and pipes that are strong and shaped right. You can make special shapes for different uses.

Tip: ShGas & Oilng the tube helps stop stress and keeps the shape correct.

Tube Mill Welding

When the edges touch, you weld them together. Welding is very important in making tubes and pipes. There are different ways to weld. Each way has its own good points. Here is a table with common welding methods:

Welding Method | Description |

TIG | Used for stainless steel, gives good quality and speed. |

Plasma | Works well for thick tubes, makes deep welds. |

ERW | Electric Resistance Welding, used a lot in tube mills. |

HF | High Frequency welding, fast and works well. |

MIG | Used for many jobs. |

Laser | Very exact welding for high-quality tubes and pipes. |

You might use high-frequency induction welding, laser welding, or TIG welding. It depends on the material and what you need. Welding melts and joins the edges to make a strong seam. You check the welds to keep defects low. If you see more than 6% rejects, you need to check your welding steps.

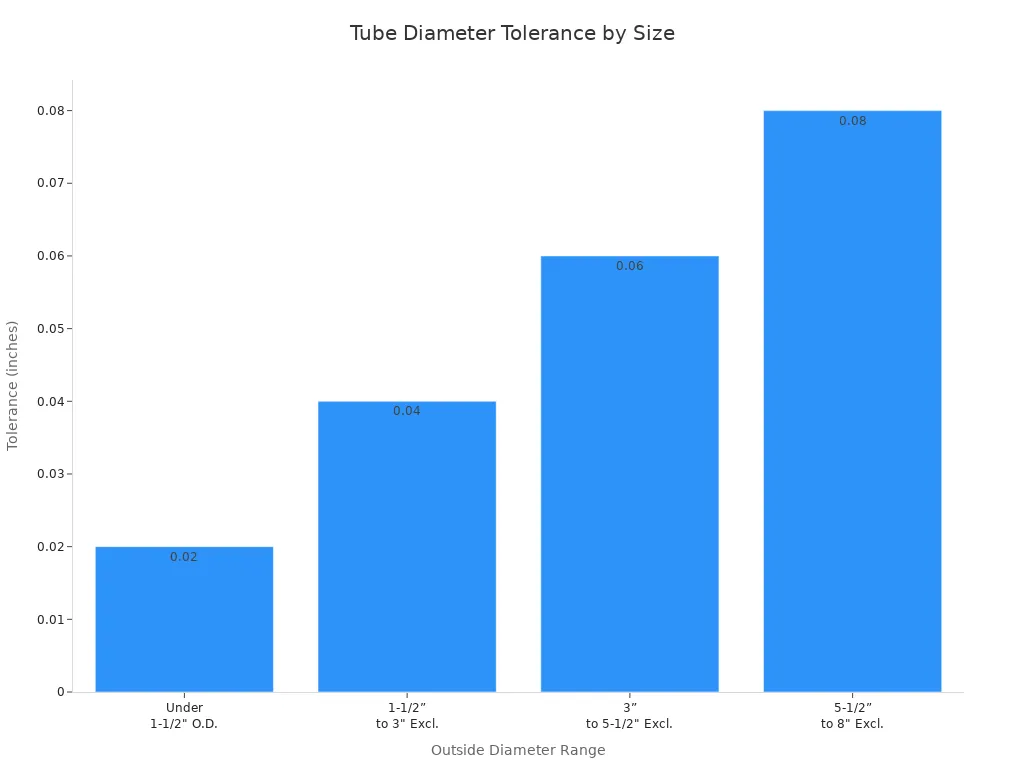

Tube Or Pipe Mill Sizing

After welding, you move the tube to the sizing part. Here, you set the diameter and wall thickness. You use carbide rolls for extra hardness and accuracy. Sizing makes sure each tube or pipe fits its job. Here are the usual tolerances:

You follow these rules to keep your work steady:

Outside Diameter Range | Tolerance |

Under 1-1/2" O.D. | .020" |

1-1/2” to 3" Excl. | .040" |

3” to 5-1/2" Excl. | .060" |

5-1/2” to 8" Excl. | .080" |

You use this formula to find wall thickness:

Calculated Wall Thickness = [(Stock Size O.D. + E - Calculated I.D.)(1.00 + F)]/2

You keep the camber in length tight so tubes do not bend or twist.

Finishing Steps

You finish by getting tubes and pipes ready to ship. You do these steps to make sure each one is good:

Straighten to fix bends.

Check and test for problems, strength, and size.

Treat the surface with pickling, passivation, polishing, or coatings to stop rust and make it look better.

Mark each pipe with grade, size, heat number, and inspection stamp.

Pack in plastic bags, hollow plates, or weaving bags to protect them.

Note: Clean surfaces and good finishing stop rust. Passivation adds a layer that helps tubes and pipes last longer.

You do all these steps so your tubes and pipes are ready for building, factories, and other jobs.

Tube And Pipe Mill Machinery

Uncoilers And Straighteners

Uncoilers hold metal coils and feed them into the mill. You can pick single-ended arms for heavy jobs. Double-ended arms work better for fast production. Most uncoilers can handle 15,000 to 25,000 pounds. Straighteners make the metal strip flat and smooth. You might use multi-roll, turkshead, or cross-roll straighteners.

Type | Description |

Single Ended Arm | Used for tough jobs and many processing lines. |

Double Ended Arm | Good for fast tube and pipe mills with bigger loads. |

Size Range | Sizes go from 3,000 lb to 40,000 lb. Most are 15,000 lb or 25,000 lb. |

Uncoilers and straighteners help keep tension and speed steady. Automatic controls and hydraulic tensioning stop slack and misalignment. You get a flat strip that feeds evenly. This helps lower mistakes later.

Forming Machines

Forming machines bend the flat strip into a round tube. You guide the metal through forming stands. Each stand bends the strip a bit more. The edges meet at the end. Advanced machines use quick-change rollers and flying saws. These cut tubes without stopping. You can stack and strap tubes for shipping automatically.

Tip: Roll forming gives tight tolerances and less waste. You can change profiles for special jobs.

Advantage | Description |

Superior dimensional accuracy | Roll forming makes tubes with tight tolerances. |

Material efficiency | It wastes little material, so it saves money. |

Customization | You can change shapes, thickness, and finishes. |

Welders

Welders join the tube edges together. High-frequency and induction welders are common. High-frequency welders use the proximity effect for fast welds. Induction welders use coils to heat the strip. Both types work with many metals and make strong seams.

Feature | High-Frequency Welding | Induction Welding |

Heating Mechanism | Uses proximity and skin effect | Induction coil heats the tube strip |

Weld Quality | Makes clean, strong welds | Welds are dense and even |

Speed | Works fast (20-50 meters/min) | Speed depends on the design |

Energy Efficiency | Saves energy | Efficient, depends on design |

Material Adaptability | Welds many metals | Works with many materials |

You prepare surfaces, control heat, and check welds. This keeps joints strong and free of defects.

Sizing Mills

Sizing mills set the final tube diameter and wall thickness. Sizing rollers shape the tube. The tube goes from oval to round as it moves through stations. A turkshead unit straightens the tube at the end. Modern rollers help keep tubes uniform, even at high speeds. You can clean and adjust the mill quickly to save time.

Cutters And Finishers

Cutters and finishers set the tube’s length and surface quality. Tube drawing equipment sets length and diameter. Straightening machines fix bends. Cutting and deburring machines smooth the ends. End finishing machines add precision. De-dimpling machines fix shape if cuts are not perfect.

Surface finish matters for looks and how tubes work.

You can use sandblasting or grinding for rough surfaces.

Accurate cutting and finishing help meet strict size and quality rules.

Seamless Vs. Welded Tube And Pipe Mills

Seamless Tube Mill Process

You start with a solid steel billet when you make a seamless steel pipe. The process uses heat and force to turn this billet into a strong, hollow tube. Here are the main steps you follow:

Heating: You heat the steel billet in a rotary furnace until it becomes soft and ready for shGas & Oilng.

Piercing: You use a piercing machine to punch a hole through the center of the hot billet. This creates a hollow shell.

Elongation and Rolling: You roll and stretch the hollow shell with special rollers. This step makes the tube longer and thinner.

Cold Drawing: You pull the rough tube through dies to get the exact size and thickness you need.

Heat Treatment: You heat and cool the tube again. This step removes stress and improves the tube’s strength and toughness.

Surface Finishing: You clean and smooth the surface to remove any rough spots.

Testing and Inspection: You check the tube for size, strength, and quality. Only tubes that pass these tests move on.

Seamless steel pipe stands out because it has no weld seam. This gives it uniform strength all around. You often use seamless pipes in places where high pressure and heat are common, like oil and gas plants. The uniform structure helps the pipe handle stress and last longer. When you use special steel grades, like 40Cr, you get even better toughness and wear resistance.

Welded Pipe Mill Process

You make welded steel pipe from flat steel strips or coils. The process is different from seamless pipes and uses forming and welding steps. Here is how you do it:

Uncoiling and Preparation: You uncoil the steel strip and make sure it is flat and clean.

Forming: You guide the strip through rollers that bend it into a round shape.

Welding: You join the edges together using electric resistance welding or high-frequency induction welding. This creates a strong seam along the length of the pipe.

Sizing and ShGas & Oilng: You use more rollers to set the final diameter and wall thickness.

Cooling and Straightening: You cool the pipe and straighten it to remove any bends.

Cutting and Finishing: You cut the pipe to the right length and smooth the ends.

Quality Inspection: You check the weld seam and the whole pipe for defects using special tests.

Welded pipes can be made quickly and in many sizes. You can use different welding methods to match the job. Good welding keeps the pipe strong and helps it resist corrosion. You use welded pipes in many places, from water lines to building frames.

Key Differences

You see big differences between seamless and welded pipes in how you make them, what machines you use, and where you use them. Here is a table to help you compare:

Factor | Seamless Pipes | Welded Pipes |

Manufacturing Process | More complex, involving heating, perforation, and rolling | Simpler, made from steel plates or strips |

Material Costs | Higher quality raw materials required | Lower material costs |

Production Efficiency | Lower due to complex processes | Higher due to simpler processes |

Quality Requirements | Higher accuracy, no internal defects | More defects possible due to welding |

Service Life | Longer and more stable due to uniform material | Shorter due to potential weaknesses in welds |

You also choose between seamless and welded pipes based on where you plan to use them:

Type of Pipe | Application Suitability |

Seamless Pipes | Preferred for high-pressure applications due to strength and uniformity. |

Welded Pipes | More versatile and cost-effective for low to medium-pressure applications. |

You pick seamless steel pipe when you need high strength, no weak spots, and the ability to handle heat and pressure. These pipes work best in oil, gas, and chemical plants.

You use welded steel pipe for jobs that need many sizes and shapes, or when you want to save money. Welded pipes fit well in construction, water supply, and general industry.

Note: New welding technology has made welded pipes stronger and more reliable. You can now use welded pipes in some high-pressure jobs, but seamless pipes still lead in the toughest places.

You get the best results when you match the right pipe and tube to the job. Seamless pipes give you top performance under stress, while welded pipes offer flexibility and lower costs for everyday use.

You see tube and pipe mills turn flat metal into strong tubes and pipes by using forming, welding, sizing, and finishing machines. Each step helps you get the right shape and quality. You choose between seamless and welded methods based on your needs. Seamless pipes work best for high-pressure jobs. Welded pipes fit many uses and save money. Tube and pipe mills give you options for different projects.

Tip: Picking the right method helps you get the best results for your job.

FAQ

What materials can you use in tube and pipe mills?

You can use steel, stainless steel, aluminum, copper, and alloys. Each material gives different strength and corrosion resistance. You pick the material based on your project needs.

How do you check tube quality in the mill?

You test tubes for size, strength, and surface defects. You use tools like ultrasonic testers, calipers, and visual checks. You mark and sort tubes that pass inspection.

Can you change tube size quickly in a modern mill?

Yes, you can switch sizes fast with quick-change rollers and automated controls. This helps you save time and make different tube sizes for many jobs.

What is the main difference between seamless and welded pipes?

Seamless pipes have no weld seam. You make them from solid billets. Welded pipes have a seam from joining edges. You use welded pipes for most jobs and seamless pipes for high-pressure work.