A tube mill bends flat metal strips into strong tubes. These tubes are very exact and used in many industries. The process begins with raw material. It ends with finished steel tubes that are ready to use. Tube mills are very important for making pipes and tubes. These are used in building, cars, and many daily products. New tube mill technology helps make steel tubes faster and better.

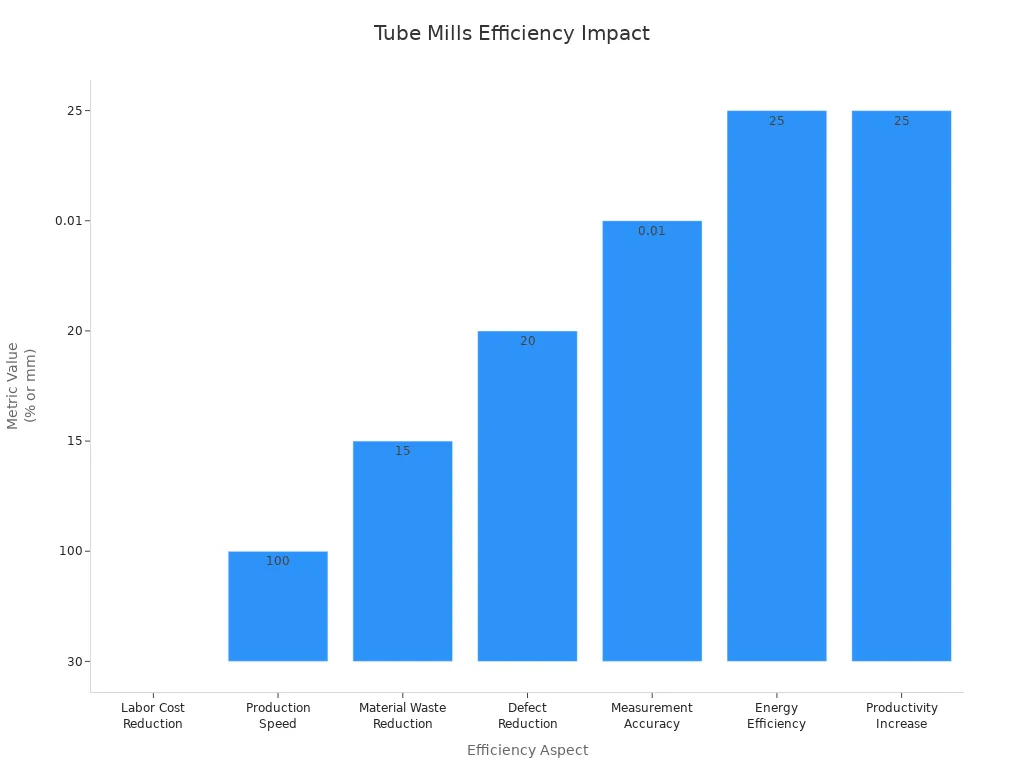

Aspect | Impact/Metric | Explanation |

Labor Cost Reduction | Up to 30% reduction | Automation makes labor cost less. |

Production Speed | Over 100 meters per minute | Fast output helps meet market needs quickly. |

Material Waste Reduction | Up to 15% reduction | Better systems help cut down on waste. |

Key Takeaways

Tube mills change flat metal strips into strong tubes. These tubes are used in many places like building and cars.

The tube mill process has many steps. It starts with uncoiling, then forming, welding, sizing, cutting, and finishing. Quality checks make sure the tubes are good.

Important tube mill parts include uncoilers, forming rollers, welding units, and sizing tools. These parts work together to make tubes quickly and correctly.

Tube mills help save money. They lower labor costs, waste less material, and make more tubes faster with smart machines.

Tube mills need regular care and skilled workers. This helps them work well, make better tubes, and stop expensive problems.

Tube Mill Overview

What Is a Tube Mill?

A tube mill is a machine that bends flat metal strips into tubes. It is important for making pipes used in many places. The steel tube mill uses new technology to make strong and exact tubes. These tubes can be made from carbon steel, stainless steel, aluminum, or titanium.

Note: Tube mills can work with many materials. These include carbon steel, high-strength low-alloy steel, advanced high-strength steels, stainless steel, aluminum, and titanium. This helps companies make many kinds of products.

Tube mills are different from other ways to make pipes. Here are some main differences:

Tube mills use fast machines that work by themselves.

Old ways, like forging and welding by hand, need more people and time.

Tube mills save money by making less waste and needing fewer workers.

They can make pipes in many sizes and from many materials.

Tube mills help companies make better products faster.

Aspect | Pipe Mill Machines (Tube Mills) | Traditional Welding (SAW, GTAW) | Extrusion |

Technology | Electric Resistance Welding (ERW) | Submerged Arc Welding (SAW), Gas Tungsten Arc Welding (GTAW) | Forcing heated billet through a die |

Productivity | High-speed, continuous production, hundreds of meters/hour | SAW: high productivity but slower setup; GTAW: slower, precise but low deposition rate | Limited by equipment size and die setup |

Flexibility | Can produce various diameters and wall thicknesses easily | Less flexible, longer setup times, more manual labor | Limited pipe sizes/shapes, less flexible |

Cost-effectiveness | Lower initial investment and operating costs, less waste | Higher labor and setup costs | High equipment cost, significant waste |

Quality Control | Precise weld control, consistent dimensional accuracy | SAW: good for large pipes; GTAW: high quality but slower | High dimensional accuracy, smooth surfaces |

Material Suitability | Mainly steel pipes | Steel and other metals | Non-ferrous metals like aluminum, copper |

Limitations | Heat-affected zone (HAZ) may require post-treatment | Labor-intensive, less flexible | Limited shapes, high waste, high equipment cost |

Tube mill technology has changed over time. At first, tube mills used simple rolling and welding. In the late 1800s, people found new ways to make seamless tubes. By the 1900s, engineers made tube mills that worked all the time and made better tubes. Today, tube mills use computers and sensors to keep things running well.

How a Tube Mill Works

A tube mill changes flat metal strips into tubes in steps. Each step uses special machines to shape, weld, and finish the tube. The process starts with a coil of steel or other metal. The coil goes into the tube mill, where it unrolls and flattens.

The main steps in tube mill work are:

Uncoiling and Preparation: The machine unrolls the steel strip and gets it ready.

Forming: Rollers bend the strip into a round or square tube.

Welding: The strip edges are heated and joined together, often with electric resistance welding (ERW).

Sizing and ShGas & Oilng: More rollers make the tube the right size and shape.

Cooling and Straightening: The tube cools and straightens to fix any bends.

Cutting and Finishing: Machines cut the tube to the right length. Some tubes get extra work, like threading or coating.

Quality Inspection: Workers and machines check the tubes for size, shape, and welds.

Packaging and Shipping: Finished tubes are bundled and sent to customers.

Tip: Modern tube mills use sensors and computers to watch the process. This keeps the tubes correct and cuts down on waste.

The way a tube mill is built affects how fast and well it works. Engineers use computers to plan the roller shapes. Strong parts and frames help the mill run fast and smooth. Automation lets workers change settings quickly, which saves time and makes more tubes. Some mills use almost all the raw material, so they do not waste much.

A steel tube mill can make many kinds of tubes for different jobs. The process is quick, exact, and saves money. This makes tube mills a good choice for companies that need lots of high-quality pipes.

Tube Mill Machine Components

Uncoiler & Slitting Line

The tube mill machine starts with the uncoiler and slitting line. The uncoiler holds steel strip coils and feeds them into the line. It checks coil details and centers them for accurate feeding. The slitting line cuts wide steel coils into thin strips. Sharp round blades slice the coil along its length. The machine then rolls up the strips for later use. This step gets steel strips ready in the right size for welded pipes. The equipment works quickly and makes sure the right material goes into the tube mill.

Forming Rollers

Forming rollers help shape metal strips. These rollers slowly bend flat strips into round or square tubes. The process uses strong pressure in many steps. This stops the metal from springing back and keeps sizes correct. Each roller has its own shape and setup. The rollers handle heavy pressure and lots of wear. The tube mill needs these rollers to make tubes with the same shape before welding. This equipment helps the metal strip get the right shape and quality for the next step.

Welding Unit

The welding unit joins the edges of the shaped strip to make a solid tube. High-frequency welding units have many benefits. They heat the weld spot fast and focus energy, so welding is quick and saves power. The welds are strong and even, with a small heat-affected area. This equipment works with different materials like carbon steel and stainless steel. The welding unit is quiet and clean, which helps the environment. Tube mill machines use this technology to make welded pipes with strong welds and little need for workers.

Tip: High-frequency welding units in tube mill machines help keep production running, lower costs, and make better welds.

Sizing & Finishing

The sizing and finishing step makes sure tubes meet strict size rules. Tube mill machines use sizing rollers and finishing tools to control the tube’s outside size and wall thickness. Cold pilgering keeps the roll die and mandrel size almost the same, so sizes stay exact. Many rolling steps make the tube thinner and longer. Magnetic abrasive finishing makes the surface smoother and keeps sizes steady. This equipment helps control tube shape and thickness, making tubes with exact sizes and smooth surfaces. Sizing and shGas & Oilng in this step gets tubes ready for cutting and finishing, making sure they meet quality standards.

Component | Function | Importance in Tube Mill Machine |

Uncoiler & Slitting | Feeds and prepares steel strips | Ensures correct material size |

Forming Rollers | Shapes strips into tubes | Maintains tube profile and accuracy |

Welding Unit | Joins strip edges to form tubes | Delivers strong, reliable welds |

Sizing & Finishing | Controls dimensions and surface quality | Guarantees final tube specifications |

Tube Mill Process

Uncoiling & Feeding

The tube mill process starts with uncoiling and feeding steel coil. Workers check the steel strip coil for problems or damage. They use a cart to put the coil on the uncoiler. The machine opens the coil’s end and straightens the strip. This removes any bends in the metal. Workers cut off the damaged head and tail of the strip. The strip goes through a shear and end welder. This joins the ends of strips so the machine can keep running. An accumulator stores the strip and gives a steady supply to the next section. This step helps the process run smoothly and keeps production high.

Forming & Welding

After feeding, the strip moves to the forming section. Rollers bend the flat strip into a round or square tube. The rollers use strong pressure to shape the metal. This stops cracks or weak spots from forming. When the strip is shaped, it goes to the welding unit. High-frequency electric-resistance welding (ERW) joins the edges together. This makes a strong bond, often stronger than the steel itself. The weld cools fast, which can cause stress and small bends. These stresses might affect the tube’s strength, especially in strong steels. Careful weld control and checks help keep welds good and prevent issues. Quality checks, like looking at the weld under a microscope, find defects and make sure the tube is safe. This step is important for making pipes that can hold heavy loads and last long.

Sizing & Cutting

Next, the tube goes to the sizing and shGas & Oilng section. Modern tube mills use rails to hold and move the tube forward. Operators set the length needed, so cutting is flexible and exact. Sizing rollers change the tube’s diameter and wall thickness to meet rules. Cutting systems use different die sets for cutting. Single-cut die sets are fast but may leave small marks on the tube ends. Dimple-free die sets use extra blades for smooth, clean ends. These are important for tubes used in furniture or appliances. Quick-change tools and jam detection keep the process safe and fast. This step makes sure each tube is the right size for the next stage.

Cutting Technology | Description | Advantages | Applications |

Single-Cut Die Set | Uses one blade and supporting jaws | Fast, simple, low cost | Conduit, fence, automotive tubes |

Dimple-Free Die Set | Uses extra blades for smooth, clean ends | No distortion, high quality finish | Furniture, appliances, recreation |

Finishing & Quality Control

The last stage is finishing and quality control. The tube cools and goes through straightening machines to fix bends. Sensors check if the tube is straight and round as it moves. Laser and infrared systems watch the weld and welding arc for problems. Color displays and alarms warn workers if something is wrong. Marking systems paint tubes for more checks, and data is saved for later review. Setup steps include electronic checks and tests like reverse bend or cone expansion. Many testing methods, like ultrasonic and eddy current, work together to find defects and keep things safe. These checks make sure every tube meets strict rules before shipping. The result is tubes that are ready to use and have the right size, shape, and weld quality.

Tip: Training workers and using the right system settings helps keep quality high and production efficient.

Steel Tube Mill Applications

Construction Industry

The construction industry uses a lot of steel tubes from tube mills. In 2023, people used more than 160 million metric tons of steel tubes worldwide. Construction used over 70 million metric tons. That is about 44% of all steel tube use. Construction is the biggest user of pipes made in tube mills. Steel tubes help build tall buildings, bridges, and utility systems. Companies like Nucor Corporation build new tube mill factories to meet the need for more steel tubing. These factories make tubing for building and clean energy projects. Government programs and worker training help these mills grow and support new infrastructure. Tube mills make strong welded steel tubing that meets tough rules for strength and lasting power.

Note: New technology in tube mill lines helps make tubes faster, lowers costs, and lets companies make pipes in different sizes for many projects.

Automotive Industry

Car and airplane makers use steel tubes from tube mills for many important parts. Tube mills make things like exhausts, fuel lines, shock absorbers, and frame pieces. These tubes must work under high pressure and heat. Tube mills use steel, aluminum, and other metals to make tubes that can handle these jobs. Special welding, sizing, and cutting make sure every tube meets strict car rules. Machines check the thickness, roundness, and welds as tubes are made. Surface treatments and shaped ends help companies get tubes ready to use. These features help make cars lighter, more complex, and better.

Tube mills help make strong tubes with thin walls for lighter cars.

They let car makers design vehicles with special tube shapes.

High accuracy keeps cars safe and parts fitting right.

Many tube shapes allow for cool and complex car designs.

Other Uses

Steel tubes from tube mills are used in many other industries besides building and cars. Oil and gas companies use tube mills to make pipes for pipelines and drilling equipment. Airplane and military groups use tubes for hydraulic systems and defense gear. Factories use steel tubes for machines like conveyors and hydraulic cylinders. Farms use tubing for watering systems and fixing heavy machines.

Industry Sector | Specific Applications and Uses |

Construction and Infrastructure | Steel tubes for tall buildings, utility systems, plumbing, and building designs |

Automotive and Transportation | Exhausts, fuel lines, and roll cages made with tube mills |

Oil and Gas | Pipes for pipelines and drilling equipment |

Aerospace and Military | Hydraulic systems for planes and defense equipment |

Industrial Machinery | Making hydraulic cylinders and conveyor machines |

Agricultural Equipment | Tubes for watering crops and fixing big farm machines |

Oil and gas companies like welded steel tubes because they are strong and dependable. Tube mills help many industries by making products that are safe and work well.

Types & Selection

Tube Mill Types

Tube mills have two main types: LG Type and LD Type. These names show up in reports and guides. LG Type tube mills are made for certain jobs. LD Type tube mills have other features for makers. Companies pick the type that fits their goals and tube needs.

Some tube mills focus on welding or how much work is done by machines. The table below shows how different tube mills work in factories:

Tube Mill Type | Production Speed | Flexibility | Notes |

Manual TIG Welding Mills | Low | High | Good for custom jobs; needs skilled workers |

Semi-Automatic TIG Mills | Moderate | Moderate | Mixes hand and machine controls |

Fully Automatic TIG Mills | High | Lower than manual types | Best for big jobs; less human mistakes |

High-Speed TIG Mills | Very High | Lower | Good for lots of tubes; needs skilled operators |

Precision TIG Mills | Moderate to High | High | Used for top-quality tubes; needs advanced machines |

Selection Criteria

Picking the right tube mill depends on many things. Makers want coil handling, like uncoilers with easy threading and tension control. The forming part must match the tube’s size and material. Welding must work with the chosen technology, like High-Frequency Induction or Contact welding. After welding, bead removal and sizing help make tubes smooth and the right size.

Quality checks use tools like ultrasonic testing and lasers. Automation helps make work faster and more steady. Adaptive Wall Thickness Control lets workers change tube thickness during making. This saves material and cuts waste. Sensors find problems fast and help fix them quickly. AI and machine learning help keep machines working and stop breakdowns.

Makers also look at how long coil joiners take, how often welders can work, and strip details like width and carbon. Weld needs and cooling, like water-cooled torches, matter too. These things help pick tube mills that meet needs and keep quality high.

Tip: Companies should talk to vendors when using new materials or changing their tube mill setup.

Maintenance & Quality

Regular care keeps tube mills working well and makes good tubes. Daily checks of rollers, bearings, and drives find problems early. Weekly cleaning and tool checks stop damage and keep cuts sharp. Monthly checks of belts, chains, and hydraulics stop breakdowns and help machines last longer.

Workers follow steps to set up tools the same way each time. They check and measure tool wear and write it down. Grinding tools on a schedule stops early or late fixes. Watching setup times and scrap rates shows when to fix or change tools. Lining up tools right, with help from experts, makes tubes more even.

Training workers in safety and fixing problems helps everything run smoothly. Sensors and data systems watch how mills work and warn about trouble. Working with good suppliers keeps raw materials strong and steady.

Maintenance Frequency | Key Activities | Impact on Lifespan and Reliability |

Daily | Check for wear, tighten bolts, oil parts, listen for odd sounds or heat | Stops small problems, keeps work steady |

Weekly | Clean up, check and sharpen tools, look at wires | Keeps cuts good, stops electric problems |

Monthly | Check belts, chains, bearings, hydraulics; change old parts and fluids | Makes machines last longer, stops big breakdowns |

Note: Regular care and good training help tube mills last longer and work well, saving money and making better tubes.

Tube mills are very important in making things today. They turn steel strips into strong pipes for many uses. Here are some main points to remember: The main parts of the tube mill work together to make good pipes. Using machines and smart controls helps make pipes faster and better. It also saves money. Taking care of the machines and having trained workers keeps everything working well. If people learn how each part works, they can make more pipes in less time. To learn more, you can watch videos, read e-books, or check expert blogs for helpful tips.

FAQ

What materials can a tube mill process?

A tube mill can process many metals. These include carbon steel, stainless steel, aluminum, and titanium. Each material needs special settings for best results.

How does a tube mill ensure tube quality?

Operators use sensors and cameras to check tube size and welds. Machines test for strength and straightness. Quality checks happen at every step.

Why do industries choose tube mills over other methods?

Tube mills work fast and make less waste. They produce tubes with exact sizes. Many industries use tube mills because they save time and money.

What is high-frequency welding in tube mills?

High-frequency welding uses electric currents to join metal edges. This method creates strong welds quickly. It also keeps the heat in a small area.

How often should tube mill machines get maintenance?

Experts suggest daily checks for wear and cleaning. Monthly inspections help prevent big problems. Regular care keeps the machine running well and makes better tubes.