* Bright Annealing Definition

Bright annealing (BA) means that the stainless steel material is heated in a closed furnace in a reducing atmosphere of inert gas and ordinary hydrogen. After rGas & Oild annealing and rGas & Oild cooling, the outer surface of the stainless steel has a protective layer, which has no reflection in the open air environment. This layer resists corrosive attack. In general, the surface of the material is smoother and brighter.

* Bright Annealed Steel Pipe

The steel pipe is processed after bright annealing. In this process, some factors are very important to the quality of the steel pipe. If the bright annealing process is improper, it will lead to cracks, which may corrode. The flexible pipe is usually in the bright annealed state.

* Preparation before bright annealing

The surface of the tube must be clean and free of other foreign objects, any material left on the surface of the tube will cause damage during processing.

Therefore, after understanding the customer's detailed needs, if the customer wants to produce high value-added industrial pipes, we generally recommend adding a cleaning process before bright annealing. The steel pipe is cleaned of dirt and oil stains with hot water, and then quickly air-dried into the furnace body for heat treatment, and the bright effect will be better.

* Protective atmosphere

The annealing atmosphere should be oxygen-free, forming a vacuum condition. The protective gas is usually dry hydrogen or argon for a brighter effect.

* Annealing temperature

The annealing temperature should be determined according to different stainless steel grades. Generally, the annealing temperature of austenitic steel is at least 1040 degrees, and the soaking time is not important. Higher temperatures are necessary for a brighter appearance. Heat as fast as possible, slow heat will cause oxidation.

Some ferritic stainless steels require lower annealing temperatures, such as TP439, which cannot be effectively bright annealed, and water quenching will form oxide scales.

After bright annealing, enter the final step of sizing and straightening, the surface of the stainless steel tube presents a bright appearance, and the bright annealed tube does not need to be pickled.

* Purpose and advantages of bright annealing:

1) Eliminate work hardening and obtain satisfactory metallographic structure.

2) Obtain a bright, non-oxidizing and corrosion-resistant surface.

3) Bright treatment keeps the rolling surface smooth, and a bright surface can be obtained without post-treatment.

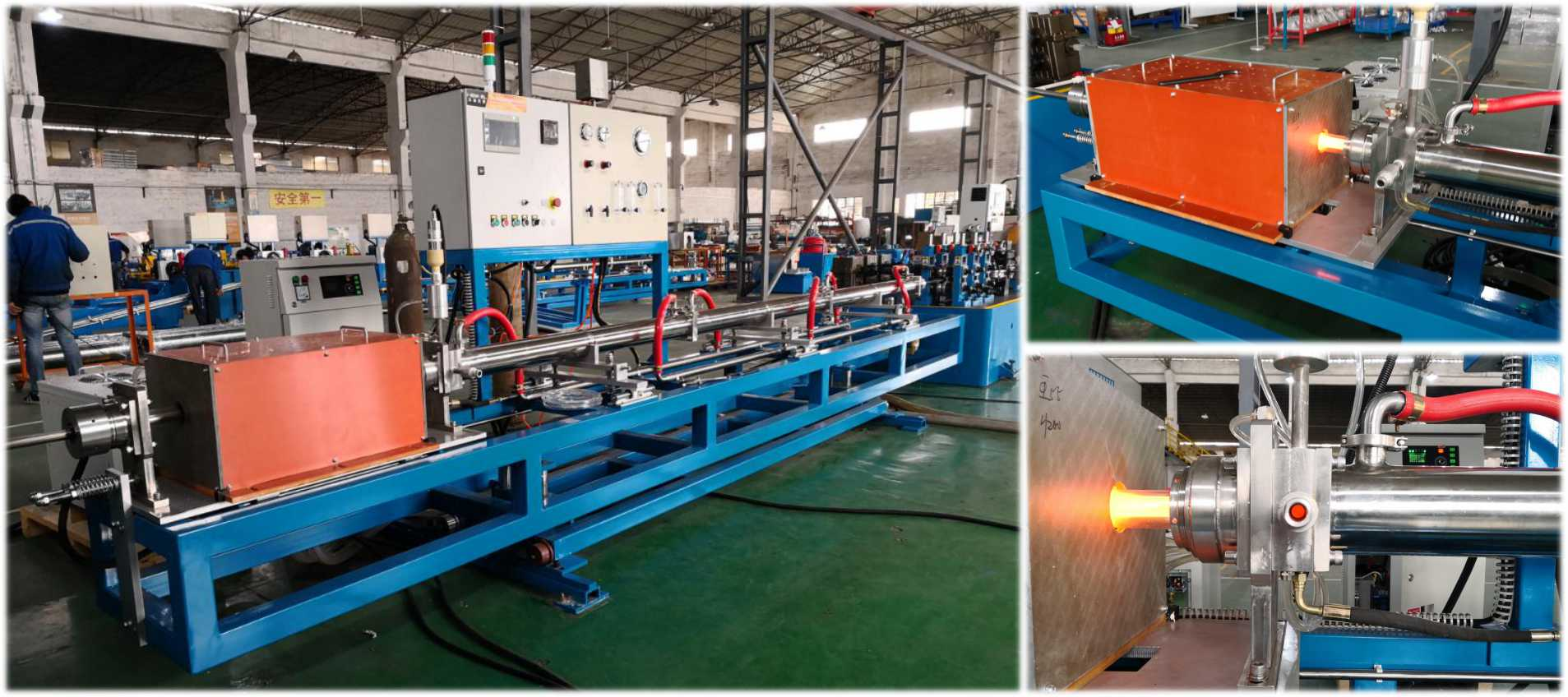

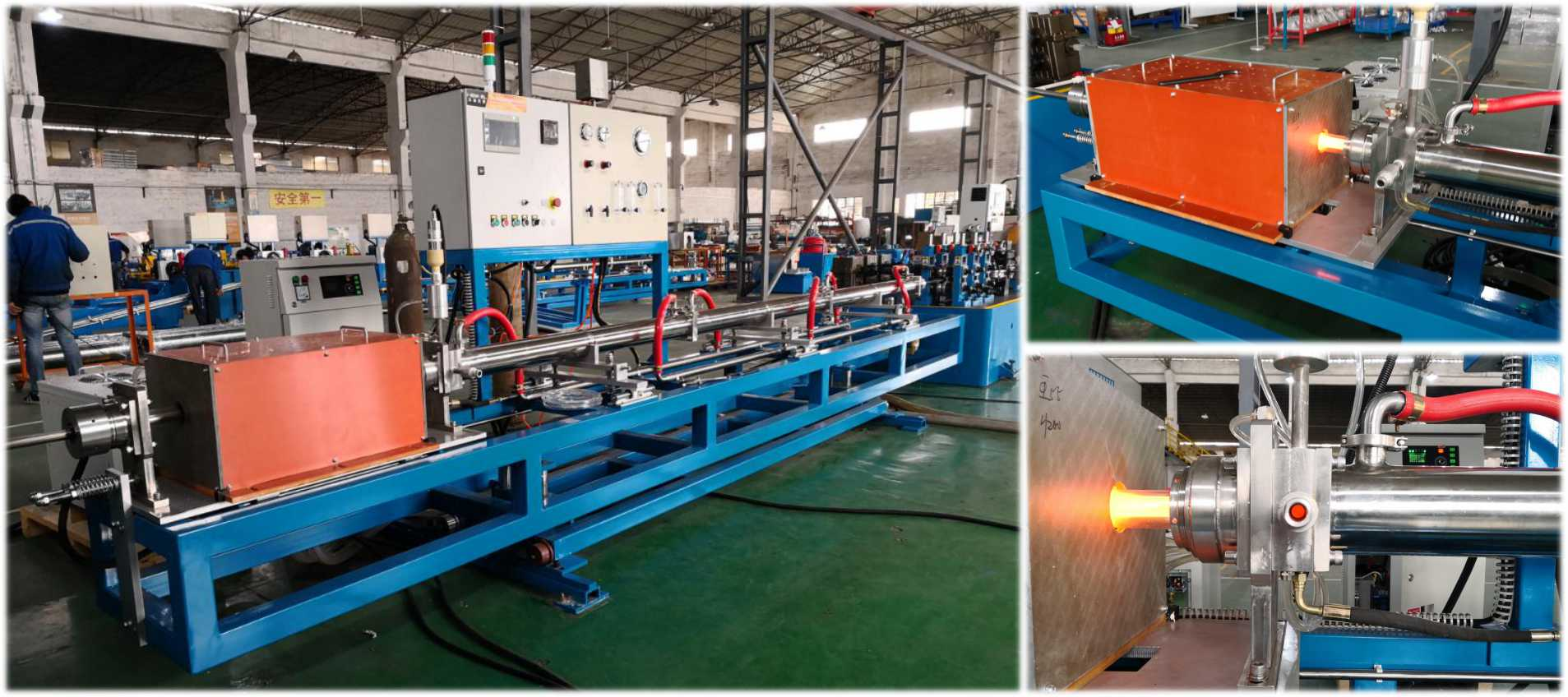

Bright solution furnaces are usually divided into two types. One is a mesh-type muffle furnace, and the other is a single-tube online annealing equipment. Generally, the mesh-type muffle furnace can process steel pipes in large quantities with high efficiency. But the shortcomings of the muffle furnace are also obvious. Due to the large interior of the furnace body, the preheating time needs to be very long, so the energy consumption is also huge. Moreover, due to poor sealing, it will also use a large amount of protective gas, but the brightening effect is unsatisfactory. The online single-tube continuous bright annealing furnace does not have the above shortcomings. Therefore, it will be a better choice for manufacturers who want to produce high value-added steel pipes or want to enter the high-end steel pipe market. Hangao Tech (SEKO Machinery) also has two different models to choose from. The Zhijin type is more energy-saving and environmentally friendly, and the thermal insulation type can obtain a better light effect.