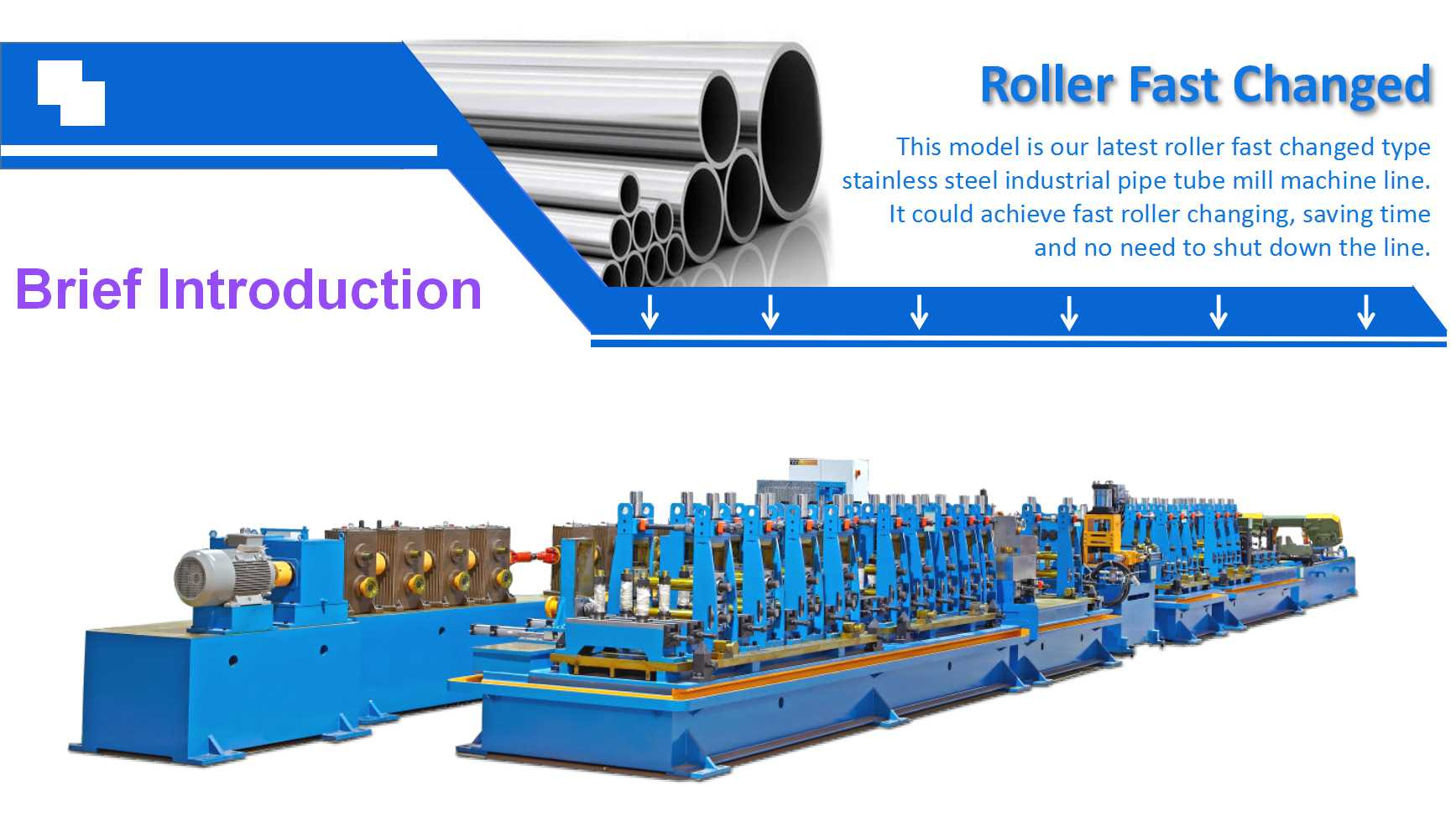

There are many types of austenitic stainless steel, 304 stainless steel is actually a kind of austenitic stainless steel. So it doesn't matter whether it's good or bad. Hangao Tech (SEKO Machinery) stainless steel industrial precision pipe production line duct making machine can easily handle various stainless steel materials such as austenite, ferrite, 2205 steel, etc. If you have special process requirements, such as internal weld leveling, in-line bright solid solution, or high quality requirements for weld processing, our custom production line can meet them all.

Austenitic stainless steels are the most commonly used stainless steel family with a recent market share of 75%. As the name suggests, the microstructure consists of the austenite phase. In the 300 series, the chromium content is 16%-22% and the nickel content is 8%-14%. While nickel increases ductility, it is prone to commodity price volatility. It reached $50,000 a ton in 2007, but is now approaching $10,000 per ton. The 200 series was developed to compensate for the high price of nickel, replacing some of the nickel content with manganese and nitrogen.

The most commonly used austenitic stainless steel 304 stainless steel

Its composition contains 18% chromium and 8% nickel, and is sometimes referred to as 18-8 stainless steel. However, this name is not recommended for general use as the tolerances in the allowable ranges for these elements overlap with other grades. For example, SS31 has similar chromium and nickel content, but it also has about 2% molybdenum for additional corrosion resistance. During welding or annealing cooling, chromium carbide precipitates form at the microstructure grain boundaries. In these regions, chromium supplies carbides at the expense of surrounding metals. Low carbon versions of austenitic stainless steels are denoted by the suffix L, such as 304L or 316L. Another way to prevent sensitization is to add titanium or niobium, which binds preferentially to carbon.

Austenitic stainless steels are not heat treatable

Some of the 200, 300, 400 series stainless steels are work hardened to become stronger during the forming process, but austenitic stainless steels are faster and easier to machine. While austenitic stainless steels generally have better overall corrosion resistance, formability and weldability, fluctuations in nickel prices have led some companies to make machining modifications to accommodate the formation of ferritic alloys.

In high temperature applications, such as exhaust systems that can reach 1650 degrees Fahrenheit, ferritic stainless steels have better tensile properties and resistance to thermal fatigue. They have lower thermal expansion and higher thermal conductivity than austenitic stainless steels. Ferritic stainless steels become brittle as the temperature decreases. The transition temperature is about 32 degrees Fahrenheit, but it depends on the alloy composition. Austenitic stainless steels do not become brittle at low temperatures.