Nutata nye ɖoɖowɔwɔ ƒe mɔnu vevi siwo wowɔna le adzɔnuwo wɔwɔ me la dometɔ ɖeka. Enye mɔnu si zãa mɔ̃ɖaŋuŋusẽwo abe tension kple shear force ene tsɔ dzia ga la ɖe edzi heɖea eƒe lãme. Esɔ nyuie na ganuwo abe ka, pɔmpiwo, kple ka siwo hiã ŋusẽ gã kple anyigba ƒe nyonyome deŋgɔ ene. Gake alesi gbegbe wòtrɔnae, ƒomevi ƒe agbɔsɔsɔ kple nuteɖeamedzi susɔe aɖe la adzɔ godoo le nutata ƒe ɖoɖoa me. Ðe Annealing ƒe atikewɔwɔ hiã na pɔmpi siwo woɖe? Na Hangao tsɔ wò vɛ be nàkpɔe egbea.

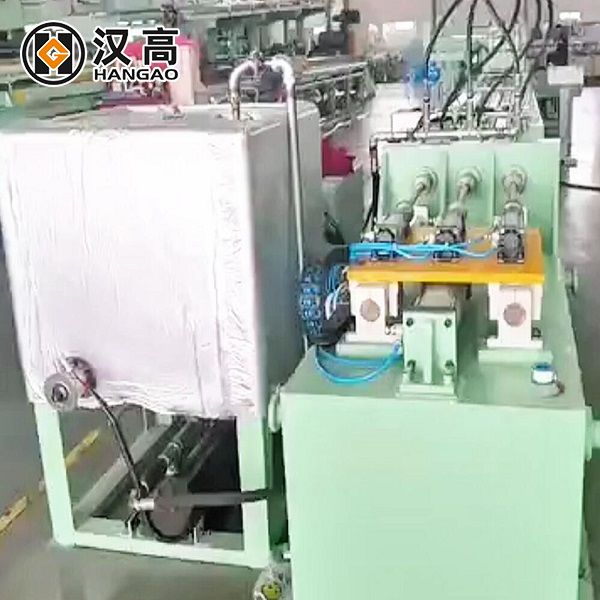

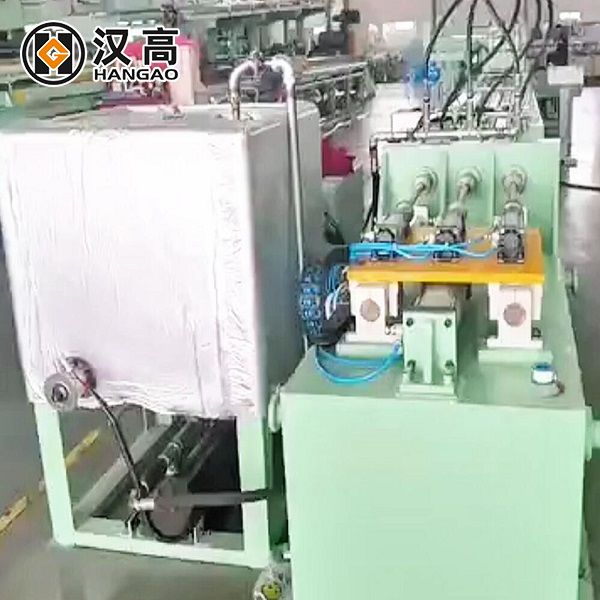

Annealing dzoxɔxɔ ƒe dɔwɔwɔ .

Annealing nye nu vevi bubu si wowɔna le nutata me. Eɖea nuteɖeamedzi ɖa le ga me eye wòɖea nukuwo ƒe liƒo ƒe ŋusẽ dzi kpɔtɔna to dzoxɔxɔ kple fafa ƒe agbɔsɔsɔ dzi ɖeɖe kpɔtɔ me, si wɔnɛ be nukuwo ƒe fafa kple woƒe dzidziɖedzi kpɔa ŋusẽ ɖe edzi. Woate ŋu ama annealing ɖe annealing blibo, spheroizing annealing, recrystallization annealing kple mɔnu bubuwo. Le wo dome la, woate ŋu azã spheroizing annealing le pɔmpiwo wɔwɔ me. To fafa dzizizitɔe kple ɣeyiɣi kple dzoxɔxɔ si dzi woɖuna me la, nukuawo lolona eye wole dzogoe ene me, si wɔnɛ be ga la ƒe ductility kple weldability nyona ɖe edzi. Recrystallization annealing ate ŋu aɖe deformation hardening kple residual stress le nusi wotsɔ wɔe me ɖa, eye wòana kristalo la nagatsi ava zu nuku yeyewo ƒe liƒowo.

Le goawo katã me la, annealing nye nutata ŋuti dɔwɔwɔ ƒe akpa vevi aɖe, si ate ŋu ana ga la naxɔ mɔ̃ɖaŋununya ƒe nɔnɔme nyuiwo kple anyigba ƒe nyonyome, kpakple dɔwɔwɔ kple eŋudɔwɔwɔ nyuie wu. Gake ele be woawɔ nu ɖe nu vovovowo kple nu vovovowo ŋu wòasɔ ɖe nɔnɔmea koŋ nu. Ne wobi ɖe mɔ̃ɖaŋununya ƒe teƒewo kple dɔwɔwɔ ƒe sisi ƒe sisi me tsitotsito la, dzoxɔxɔ ƒe dɔwɔwɔ ƒe ɖoɖo si wowɔ la te ŋu naa kakaɖedzi be nu mamlɛtɔa ƒe nyonyome kple eƒe dɔwɔwɔ.

1. Dɔwɔwɔ ƒe vovototowo .

1) Annealing ƒe gakpo si wotsɔna ƒoa gae ƒe pɔmpi .

Zi geɖe la, ehiãna be woawɔ gakpo siwo wotsɔ wɔa nu fafɛe la ƒe pɔmpiwo le ewɔwɔ ƒe ɖoɖoa me be woƒe mɔ̃ɖaŋununya ƒe nɔnɔmewo kple woƒe dɔwɔwɔ nanyo ɖe edzi. Nusi koŋ wowɔnae nye: Gbã la, wodoa dzo na gakpo si wotsɔ wɔa gayibɔe si wofa la vaseɖe dzoxɔxɔ aɖe koŋ dzi, emegbe wotsɔa dzoxɔxɔ nɔa eme hena ɣeyiɣi aɖe, eye mlɔeba la, wofae blewu. Dɔ sia wɔwɔ ate ŋu atrɔ asi le gakpo si wotsɔ wɔa pɔmpi si me vuvɔ le ƒe nukuwo ŋu, aɖe nuteɖeamedzi ɖa, eye wòana gakpoa ƒe pɔmpia ƒe plasticy kple eƒe sesẽ nanyo ɖe edzi.

2) Ga si wotsɔ wɔa gakpo si wotsɔna ƒoa gae si me womefa o .

Le go aɖewo me la, woate ŋu atsɔ gakpo siwo wotsɔna ƒoa gae siwo wotsɔa vuvɔ wɔe hã awɔ annealed evɔ womatsɔ wo aƒoe o. Le kpɔɖeŋu me, ne gakpo ƒe pɔmpi si wofa la ƒe gli ƒe titrime le sue eye eƒe didime le sue la, mehiã be woawɔ annealing hafi woate ŋu akpɔ mɔ̃ɖaŋununya ƒe nɔnɔme siwo hiã la gbɔ o. Tsɔ kpe ɖe eŋu la, ne woatsɔ gakpo si wotsɔ wɔa nu fafɛe la awɔ dɔe emegbe, abe vuvɔŋɔli, welding kple dɔwɔwɔ bubuwo ene la, woate ŋu aɖe annealing ɖa.

2. Vovototo le dɔwɔwɔ me .

1) Annealing ƒe gakpo si wotsɔna ƒoa gae ƒe pɔmpi .

To annealing me la, woate ŋu akpɔ gakpo si wotsɔna ƒoa gae ƒe pɔmpi si wofa la ƒe nuku ƒe lolome dzi, si ana mɔ̃ɖaŋununya ƒe nɔnɔme siwo le gakpoa ƒe pɔmpia me nanyo ɖe edzi. Etɔxɛe la, annealing ate ŋu aɖe gayibɔ ƒe pɔmpia ƒe kutsetse ƒe ŋusẽ kple tensile ƒe ŋusẽ dzi akpɔtɔ, gake ate ŋu ana eƒe plasticity kple eƒe sesẽ nanyo ɖe edzi. Tsɔ kpe ɖe eŋu la, annealing ate ŋu aɖe nuteɖeamedzi ɖa hã eye wòana gakpo ƒe pɔmpia ƒe dɔwɔwɔ nanyo ɖe edzi.

2) Ga si wotsɔ wɔa gakpo si wotsɔna ƒoa gae si me womefa o .

Ne womewɔ annealing o la, mɔ̃ɖaŋununya ƒe nɔnɔme siwo le gakpo si wotsɔ wɔa nu fafɛe la ate ŋu agblẽ. Esi wònye be nuteɖeamedzi susɔewo le gakpo si wotsɔ wɔa pɔmpia ƒe pɔmpi si me vuvɔ le wɔwɔ me ta la, ne womewɔ annealing o la, nuteɖeamedzi siawo akpɔ ŋusẽ ɖe mɔ̃ɖaŋununya ƒe nɔnɔme siwo le gakpoa ƒe pɔmpia dzi la dzi. Tsɔ kpe ɖe eŋu la, gakpo si wotsɔ wɔa pɔmpi si me vuvɔ le ƒe nuku ƒe lolome hã ate ŋu alolo wu, si ana wòagblẽ nu le eƒe plastik kple eƒe sesẽ ŋu.

3. Afɔɖeɖewo .

Le mɔ̃ si wotsɔna ƒoa tsii si me vuvɔ wɔna le me la, ele be woade dzesi akpa siwo gbɔna:

1) Dzoxɔxɔ si sɔ .

Ne wole mɔ̃ si me vuvɔ le la ƒom la, ehiã be woalé dzoxɔxɔ ƒe dzoxɔxɔ ƒe ɖekawɔwɔ me ɖe asi be mɔ̃ si me vuvɔ le la nagagblẽ o. Le fafa ƒe ɖoɖoa me la, ehiã hã be woalé fafa ƒe ɖekawɔwɔ me ɖe asi be woaƒo asa na kuxiwo abe tube ƒe ʋuʋu ene.

2) Kpɔ ɣeyiɣi si woatsɔ awɔ annealing la dzi .

Zi geɖe la, ɣeyiɣi si woatsɔ awɔ annealing la didina, eye ele be woakpɔ ɣeyiɣia dzi nyuie be teƒe ɖesiaɖe ƒe dzoxɔxɔ nasɔ pɛpɛpɛ alesi woate ŋui be woakpɔ egbɔ be annealing ƒe ŋusẽkpɔɖeamedzia le eme.

3. Fafa mɔnu tiatia si sɔ .

Ne wowɔ annealing vɔ la, ele be woadzra mɔ̃ si me vuvɔ le la ɖo ɖe mɔ si wotu nu ɖo nu alo ele be woawɔ ametakpɔnu bubuwo be woatsɔ axe mɔ ɖe tɔtrɔ siwo mehiã o nu le nudzraɖoƒea.

Kpuie ko la, mɔ̃ si wotsɔna ƒoa ʋuƒoe si me vuvɔ wɔna le la nye mɔnu vevi aɖe le mɔ̃ siwo me vuvɔ le wɔwɔ me. To annealing ƒe ɖoɖoa dzi kpɔkpɔ nyuie me la, woate ŋu ana mɔ̃ si wotsɔna ƒoa nu na ame ƒe nɔnɔme ŋutɔŋutɔ kple eƒe wɔwɔme nanyo ɖe edzi, woate ŋu akpɔ nu mamlɛtɔa ƒe nyonyome dzi, eye woate ŋu akpɔ asisiwo ƒe nuhiahiãwo gbɔ nyuie wu.

4. Kpuie ko .

Kpuie ko la, vovototo si le gakpo siwo wotsɔ wɔa nu fafɛe ƒe annealing kple non-annealing dome la le vovototo siwo le dɔwɔwɔ kple dɔwɔwɔ me. Le gakpo ƒe mɔ̃ siwo wotsɔ fa miamiamia wɔwɔ le goawo katã me gome la, annealing hiã be woatsɔ ana mɔ̃ɖaŋununya ƒe nɔnɔmewo kple dɔwɔwɔ le gakpo ƒe mɔ̃wo ŋu nanyo ɖe edzi. Gake le go aɖewo me, abe ne gakpo ƒe mɔ̃ si wofa ɖe vuvɔ me ƒe gli ƒe titrime le sue ene la, eƒe didime le sue, alo ehiã be woawɔ dɔ tso eŋu emegbe la, ɖewohĩ womawɔ annealing o.