Ngokuvamile, inqubo yokuhlanza insimbi yensimbi ye-welding yensimbi engenasici, isebenzisa indlela ye-argon arc ye-arc arc. Njengamanje, inqubo evuthiwe kunazo zonke amapayipi angenazinsimbi embonini asembonini asashizi i-argon arc arc.

I-Tig Welding

Amapayipi wensimbi engagqwali adinga ukungena okujulile, akukho okufakwayo kwe-oxide, futhi kube yindawo encane ethinteke ukushisa ngangokunokwenzeka. UTungsten inert igesi wavikela i-Argon Arc Welding inokuguquguquka okuhle, ikhwalithi ephezulu ye-welding kanye nokusebenza okuhle kokungena. Imikhiqizo yayo isetshenziswa kabanzi embonini yamakhemikhali. , Imboni yenuzi kanye nezimboni zokudla zisetshenziswa kabanzi.

Ngaphambi kokushiswa, ipayipi kufanele lihlanzwa ngegesi. Ngemuva kokufudumala, ukuhlanganiswa kwe-welding kufanele kuhlolwe futhi kuhlolwe ingcindezi, bese kuthi ipayipi lihlanzeke kabili (i-nitrogen ingasetshenziselwa igesi ehlanzekile), bese ifaka ipayipi ngamanzi ahlanzekile. Faka isixazululo se-sodium hypochlorite emanzi ahlanzekile, futhi ngemuva kokufaka ipayipi, uphinde ushaye iphayiphu futhi kuze kube yilapho kunesixazululo se-sodium hypochlorite sihlala emanzini agcwele amanzi. Amapayipi ensimbi angenasici afakwe ngale ndlela ahlangane namazinga omhlaba wonke wamapayipi ensimbi angagqwali, njengamanje aphesheya. Amapayipi ensimbi ahlanzekile futhi angenasici afakwa inzalo kakhulu ngemisebe ye-ultraviolet ngemuva kokushiswa, futhi i-Argon arc welding isalungele ukufudumala. Insimbi engenasici isetshenziswa kabanzi kwimishini yokudla (ikakhulukazi i-hygiene hygiene grade amapayipi ensimbi angenasici), iningi lawo ngensimbi engenacala, futhi ukukhiqizwa kwalo kuqedwa kakhulu yinqubo ye-welding.

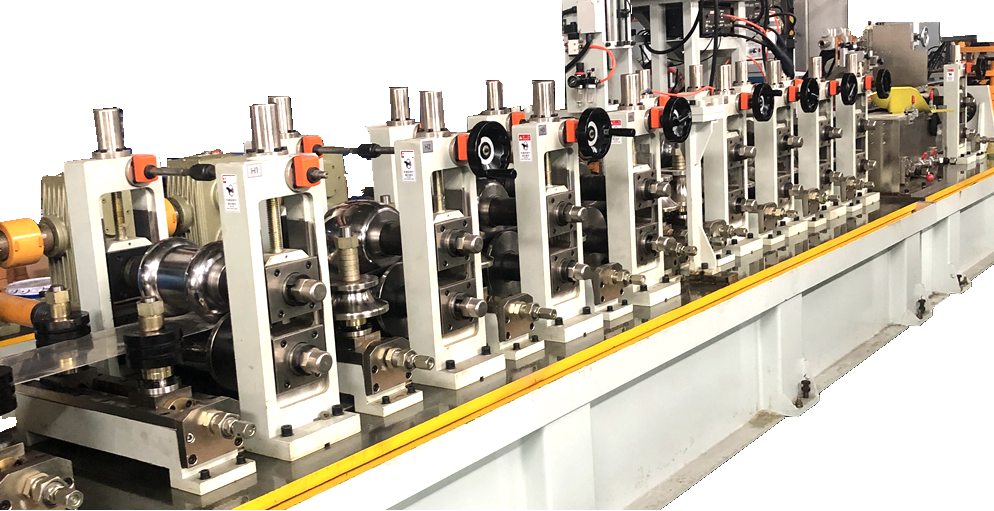

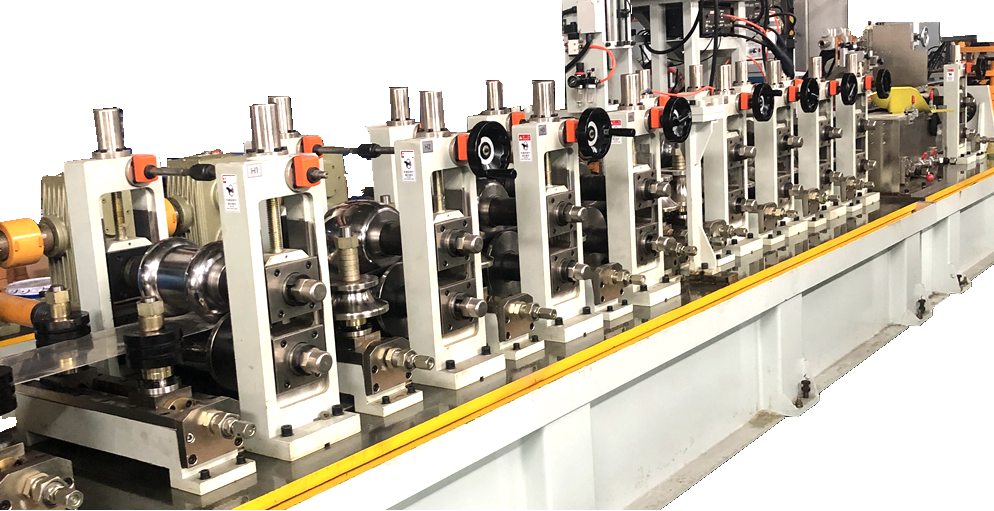

Imvamisa kakhulu i-Welding

I-Welding ephezulu kakhulu isetshenzisiwe ekukhiqizeni amapayipi e-carbon yensimbi ye-welded iminyaka engaphezu kwengu-40, kepha ukusetshenziswa kwamapayipi ensimbi angenasisekelo e-Welding Stering Pipes ubuchwepheshe obusha obusha. Umnotho wokukhiqizwa kwawo wenza imikhiqizo yawo isetshenziswe kabanzi emikhakheni yomhlobiso wezakhiwo, izinto zasendlini kanye nezinhlaka zemishini. Inzuzo yayo ukuthi ijubane lokukhiqizwa liyashesha, kepha ubunzima buyasobala. Lapho kusetshenziswa i-welding ephezulu ye-welding ukucubungula insimbi engagqwali, uma isipiliyoni sobuchwepheshe sabasebenzi bezinkinga singacebile ngokwanele, kungenzeka ukuthi ukugcotshwa kuzokwenzeka kaningi, futhi okufekodwa kuzokwanda kakhulu.

I-Laser Welding

I-Laser Welding yindlela ye-welding esebenzisa ukushisa okukhiqizwe ngokubopha i-weldenting ngogongolo lwama-laser olugxile njengomthombo wamandla. Ngenxa yezakhiwo ze-optical zokukhanya kwe-laser ezifana nokubhekisisa nokugxila, i-laser welding ilungele ukufudumala kwezingxenye ezincane nezingxenye ngokufinyeleleka okungalungile. I-Laser Welding futhi inezimpawu zokufaka okushisa okuphansi, i-delform encane ye-welding, futhi ayithintwa izinkambu ze-electromagnetic, okwamanje, i-laser welding ayisetshenziswa kabanzi emkhakheni wamapayipi wensimbi engagqwali. Ikakhulukazi ngenxa yentengo ephezulu yama-lasers kanye nokuguqulwa okuphansi okuphansi kwe-electro-optical. Phakathi kwazo, izindleko zokufaka zokufaka zemishini nemishini kuyinto ebalulekile yengqinamba. Kodwa-ke, kuyabonakala ukuthi i-laser welding izoba umkhuba wokuthuthuka kwezentuthuko embonini. Umshini wePipe wePipe we-Laser Welding we-Laser Welding we-Sales futhi kugxilwe Hangao tech (seko mishini) eminyakeni yamuva nje