Jɛnɛral wan, sanitayz ɛn stenlɛs stiɛl paip wɛldin prɔses, yuz argɔn ak wɛldin mɛtɔd. Naw, di mɔs machɔ prɔses fɔ stenlɛs stiɛl wɛlded paip dɛn na di industri stil na men wan na argɔn ak wɛldin.

Tig welding .

Staynlɛs stiɛl wɛlded paip dɛn nid dip penɛtrɛshɔn, nɔ ɔksayd inklushɔn, ɛn as smɔl wan ɔt-afɛkt zon as pɔsibul. Tungsten Inert Gas Shielded Argon Arc Welding gɛt gud adaptabiliti, ay wɛldin kwaliti ɛn gud penɛtreshɔn pefɔmɛns. Dɛn kin yuz in prɔdak dɛn bɔku bɔku wan na kemikal industri. , dɛn kin yuz nyuklia industri ɛn it industri bɔku bɔku wan.

Bifo dɛn wɛl, dɛn fɔ pul di paip layn wit gas. Afta dɛn dɔn wɛl, dɛn fɔ chɛk di wɛldin jɔyn ɛn tɛst di prɛshɔn, dɔn dɛn fɔ pul di paip tu tɛm (dɛn kin yuz di naytrɔjen fɔ di Purge gas), dɔn sok di paip wit klin wata. Ad sodium hypochlorite solution to di klin wata, ɛn afta yu dɔn sok di paip, flash di paip bak te no sodium hypochlorite solushɔn nɔ de na di wata we de flash. Di stenlɛs stiɛl paip dɛn we dɛn wɛlda dis we mit di intanashɔnal standad fɔ sanitayz stenlɛs stiɛl paip dɛn, we de na ɔda kɔntri naw. Sanitary ɛn stenlɛs stiɛl paip dɛn kin mɔs stɛrilayz bay ɔltra vayolɛt rayt afta wɛldin, ɛn Argon arc wɛldin stil fayn fɔ wɛldin. Dɛn kin yuz stenlɛs stiɛl bɔku bɔku wan na tin dɛn we dɛn kin yuz fɔ it (espɛshali di gred dɛn we dɛn kin yuz fɔ klin di it dɛn we dɛn kin yuz fɔ klin di it dɛn we dɛn kin yuz fɔ klin di it dɛn we dɛn kɔl stenlɛs stiɛl paip dɛn), bɔku pan dɛn na Austenitik stenlɛs stiɛl, ɛn dɛn kin dɔn fɔ mek am bay we dɛn de mek di wɛldin prɔses.

High Frequency Welding .

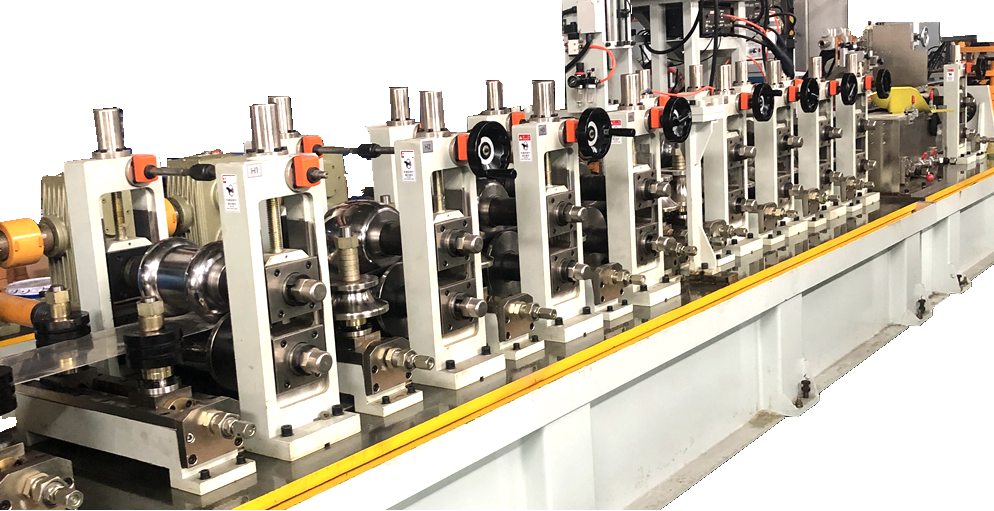

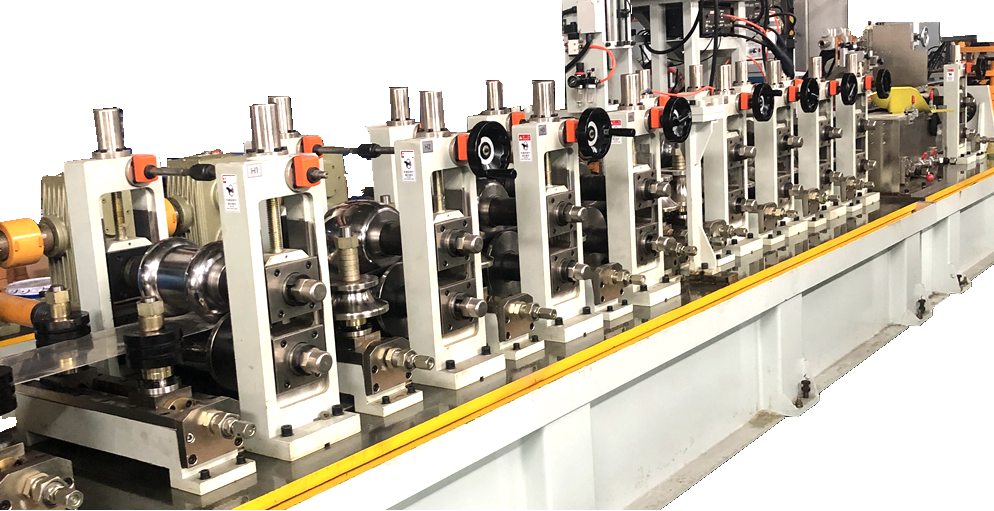

Dɛn dɔn yuz ay-frikyuɛnsi wɛldin fɔ mek dɛn mek paip dɛn we gɛt kabon stiɛl fɔ pas 40 ia, bɔt di we aw dɛn de yuz sanitayz stenlɛs stiɛl paip fɔ wɛldin stenlɛs stiɛl paip dɛn na nyu teknɔlɔji. Di ikɔmi fɔ in prodakshɔn de mek in prɔdak dɛn de yuz mɔ na di fild dɛn fɔ akitɔk dɛkɔreshɔn, os aplayans ɛn mɛkanikal strɔkchɔ dɛn. I advantej na dat di prodakshɔn spid fast, bɔt di disadvantej sɛf klia. We dɛn yuz ay-frikyuɛnsi wɛldin fɔ prosɛs stenlɛs stiɛl, if di tɛknikal ɛkspiriɛns fɔ di dibɔg pipul dɛn nɔ rich inof, i rili pɔsibul se pɔrfɔreshɔn go apin bɔku tɛm, ɛn di kɔnsumabl dɛn go rili bɔku.

Laser welding na

Laser Welding na welding method we de yuz di hot we dɛn de jenarayz bay we dɛn de bɔm di wɛldmɛnt wit wan fɔs laser bim as ɛnaji sɔs. Bikɔs ɔf di optik prɔpati dɛm fɔ laser layt lɛk refrɔkshɔn ɛn fɔs, laser wɛldin rili fayn fɔ di wɛldin fɔ maykro pat ɛn pat dɛm wit po aksessibiliti. Laser welding gɛt bak di kwaliti dɛm fɔ di lɔw ɔt input, smɔl wɛldin difɔmeshɔn, ɛn i nɔ afɛkt bay ilɛktromagnetik fil dɛm bɔt, naw, laser wɛldin nɔ bin dɔn yuz bɔku bɔku wan na di fil fɔ stenlɛs stiɛl wɛlded paip dɛm. Menli bikɔs ɔf di ay prays fɔ laser ɛn lɔw ilɛktro-ɔptik kɔnvɔshɔn efyushɔn. Na dɛn wan ya, di ay input kɔst fɔ mashin ɛn ikwipmɛnt na di men kɔnstrakshɔn factor. Bɔt, i kin bi se laser wɛldin go bi di fiuja divɛlɔpmɛnt tren fɔ di industri. High-speed laser welding paip mek mashin fɔ sɛl dakt prodakshɔn layn na di men tin bak we dɛn bin de pe atɛnshɔn pan Hangao Tech (Seko Machinery) insay di las ia dɛn .