Kazhinji, hutsanana uye isina tsvina pombi yelding maitiro, uchishandisa argon arc tilding nzira. Parizvino, iyo yakakura kwazvo maitiro yeStanless Steel Weld Pipe muindasitiri ichiri kunyanya argon arc tuling.

Tig tulating

Pipms is Standled yedopu inoda kupinza zvakadzama, hapana macarides ekuda, uye sediki nzvimbo inokanganisa. Tungsten Inert Gasi Workerry Argon Arc Welding ane Akanaka Accaptability, yakakwira Welting mhando uye yakanaka yekupinza basa. Zvigadzirwa zvaro zvinoshandiswa zvakanyanya muindasitiri yemakemikari. , indasitiri yenyukireya uye maindasitiri echikafu anoshandiswa zvakanyanya.

Usati wasvitsa, pombi yacho inofanira kucheneswa negesi. Mushure mekunge talding, iyo yakabatanidzwa yakabatanidzwa uye kudzvanywa kunoedzwa, uye ipapo pombi yacho inofanira kucheneswa kaviri (nitrogen inogona kushandiswa kwegomba), wobva wanyudza pombi nemvura yakachena. Wedzera sodium hypochlorite mhinduro kumvura yakachena, uye apedza pombi, pombi zvakare kusvikira pasina sodium hypochlorite mhinduro inosara mumvura inobhururuka. Iyo Stain Transpes inoyevedza nenzira iyi sangana neyekunze mwero nekuda kwehutsanana stainless simbi mapipi, iri kunze kwenyika. Hutsanana uye Stainless Steel mapaipi anonyanya kusungwa neiyo Ultraviolet riys mushure meTalk, uye Argon Arc Welding ichiri yakakodzera kune Welding. Simbi isina simba inoshandiswa zvakanyanya mumidziyo yechikafu (kunyanya chikafu chehurongwa hwekudya chisina tsvina simbi.

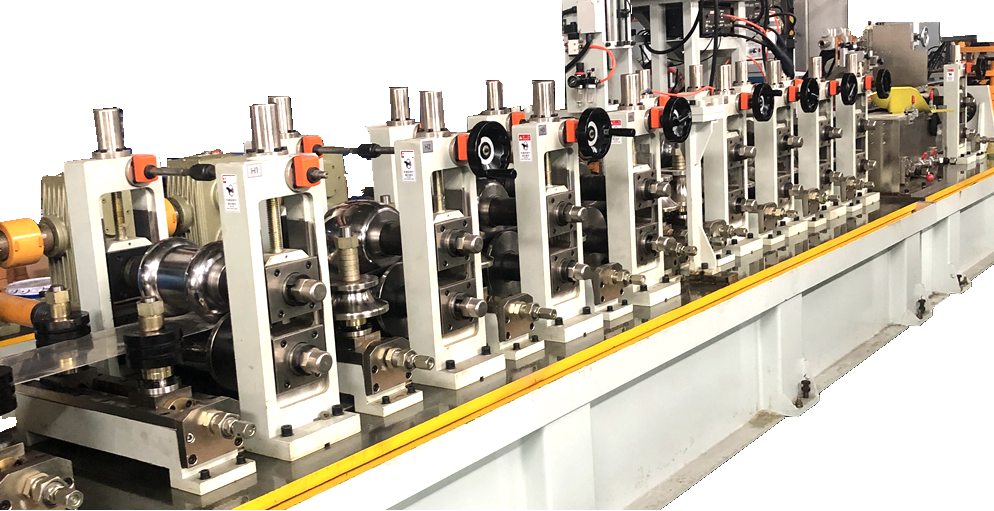

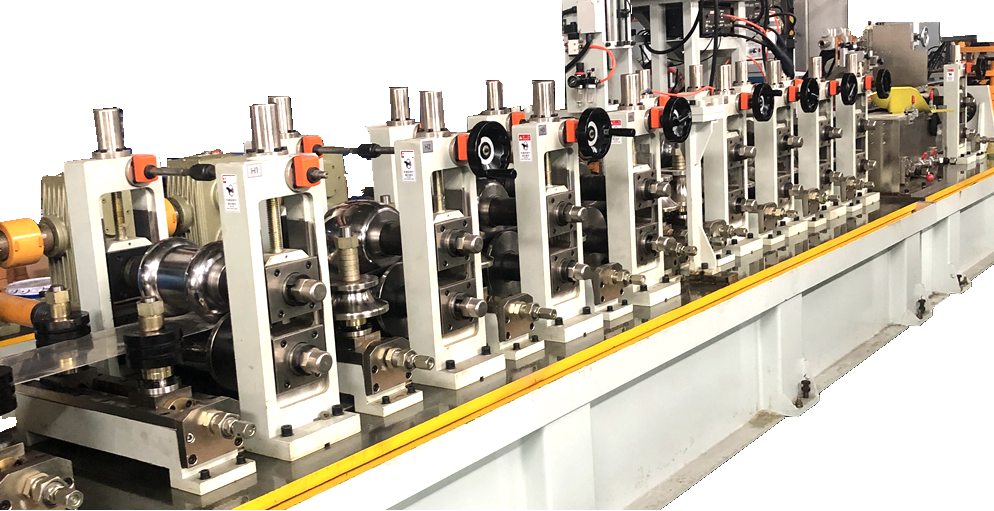

High Frequency Walding

High-frequency Welding yave ichishandiswa mukugadzirwa kweCarbon Steel yePipes kwemakore anopfuura makumi mana, asi kushandiswa kwehutsanana zvibayiro zvekutengesa zvisina mwero. Hupfumi hwechigadzirwa hwayo hunoita kuti zvigadzirwa zvaro zvinoshandiswa zvakanyanya muminda yekuzvishongedza kwemidziyo, zvivakwa zveimba uye zvivakwa zvemumhanzi. Kubatsira kwayo ndekwekuti kumhanya kwekugadzira kuri kukurumidza, asi kusanganisa kuri pachenawo. Kana yakakwira-frequency tulting inoshandiswa kuita simbi isina simba, kana ruzivo rwehunyanzvi rwekuita nharo haruna kupfuma zvakakwana, zvinokwanisika kuti kutsaura kuchaitika kazhinji, uye zvinonikwa zvichawedzera.

Laser weldering

Laser Welding ndiyo nzira inoshandisa iyo inopisa inogadzirwa nekubatidza iyo yeldment ine yakatarisana laser beam sosi yesimba. Nekuda kweiyo Optical Properties yeLaser Chiedza chakadai sekuramba uye kutarisa, Laser Welding yakakodzera kwazvo kune iyo yelating yezvikamu zvemifananidzo uye zvikamu zvisina kunaka zvinowanikwa. Laser Welding zvakare ane hunhu hwezvakadzika zvekupisa Kunyanya nekuda kwemutengo wakakwira we lasers uye yakaderera electro-Optical kutendeuka kushanda. Pakati pavo, iyo yakanyanya yekuisa mari yemuchina nemidziyo ndiyo yakakosha constraint chinhu. Nekudaro, zvinoonekwa kuti Laser Welding ichave iri ramangwana rekusimudzira maitiro eindasitiri. Yakakwira-kumhanya Laser Welding pombi kugadzira muchina wekutengesa Duct Production Line zvakare inotarisisa Hangoo Tech (Seko Machinery) yemakore apfuura