A ka c’a la, saniya ni inox pipe welding kɛcogo, ni argon arc welding fɛɛrɛ ye. Sisan, fɛɛrɛ min kɔgɔlen don ka tɛmɛ baara tɔw bɛɛ kan, n’o ye pipe weldalen ye, o ye hali bi argon arc welding ye kosɛbɛ.

TIG welding .

Pibiliki minnu bɛ sɔgɔ ni nɛgɛ ye, olu bɛ don kosɛbɛ, oksizɛni tɛ don u la, ani yɔrɔ fitinin min bɛ funteni sɔrɔ, o bɛ se ka kɛ. Tungsten gazi inert shielded argon arc welding bɛ ni ladamuni ɲuman ye, welding quality ka bon ani doncogo ɲuman. A ka fɛn dilannenw bɛ baara kɛ kosɛbɛ kemikɛli baara la. , nukiliya baarakɛlaw ni dumuniko baarakɛyɔrɔw bɛ baara kɛ kosɛbɛ.

Sani welding ka kɛ, pibiliki ka kan ka saniya ni gazi ye. A welding kɔfɛ, welding joint ka kan ka sɛgɛsɛgɛ ani ka tansiyɔn sɛgɛsɛgɛ, o kɔfɛ pibiliki ka kan ka saniya siɲɛ fila (azote bɛ se ka kɛ gazi saniyalen na), ka sɔrɔ ka pibiliki su ni ji sanuman ye. Aw bɛ ipokuloriti sodiyɔmu kɛ ji sanuman na, ka sɔrɔ ka pibiliki su ji la, aw bɛ pibiliki ko tuguni fo ka se ipokuloriti sodiyɔmu si kana to ji wulilen na. Pipe minnu bɛ kɛ ni nɛgɛ ye, olu bɛ welda nin cogo la, olu bɛ diɲɛ sariyaw dafa, minnu bɛ kɛ ka ɲɛsin saniyalanw ma, minnu bɛ kɛ ni nɛgɛ ye, minnu bɛ jamana kɔkan sisan. Saniya ni nɛgɛma pipew fanba bɛ sterilize ni ultraviolet rays ye welding kɔfɛ, ani argon arc welding bɛnnen don hali bi ka welding kɛ. Nɛgɛ min tɛ sɔgɔ, o bɛ kɛ ka caya dumunikɛminɛnw na (kɛrɛnkɛrɛnnenya la dumuni saniyacogo min bɛ kɛ ni nɛgɛ ye), a fanba ye nɛgɛ ye min tɛ sɔgɔ, wa a dilanni bɛ dafa kosɛbɛ ni sɔgɔli kɛcogo ye.

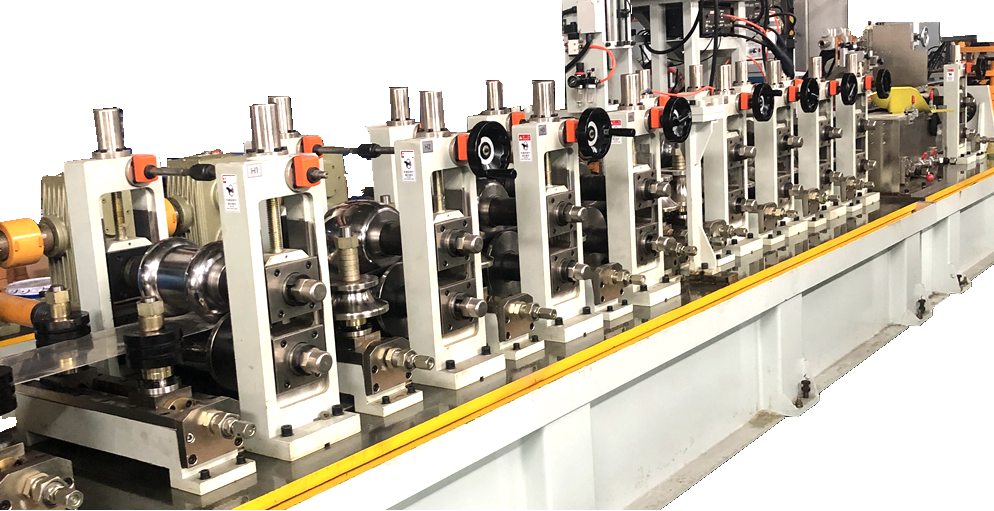

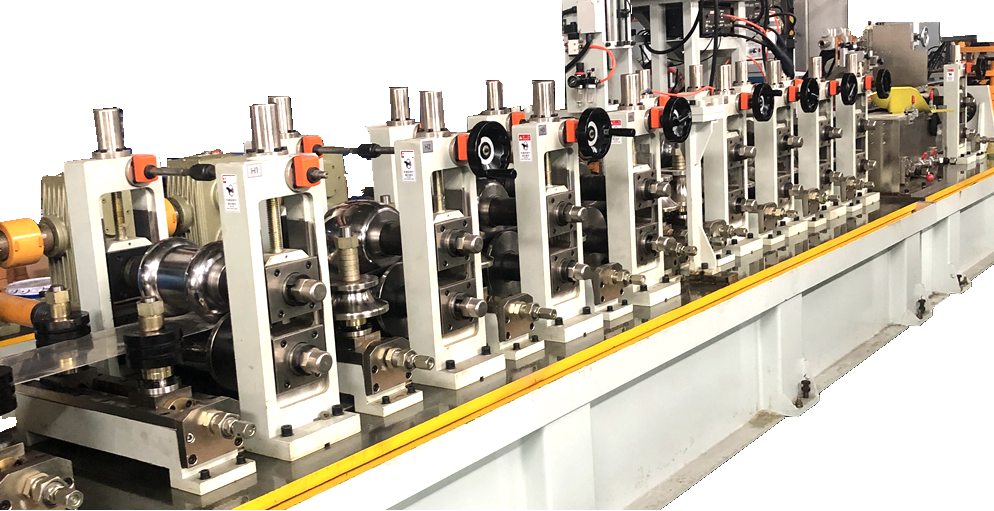

welding frequency .

Baara kɛra ni welding ye min bɛ kɛ ka ɲɛ, o bɛ kɛ ni pipew ye minnu bɛ siri ni nɛgɛ ye ka tɛmɛ san 40 kan, nka baara kɛli ni saniyalanw ye minnu bɛ kɛ ni nɛgɛ ye, nɛgɛ minnu bɛ kɛ ni nɛgɛ ye, olu ye fɛɛrɛ kura ye min bɛ kɛ ni nɛgɛ ye. A ka sɛnɛfɛnw sɔrɔko b’a ka fɛn dilannenw kɛ fɛn ye min bɛ kɛ ka caya fɛn dilanni masirili la, du kɔnɔ minɛnw ani masinw na. A nafa ye ko sɛnɛfɛnw bɔli teliya bɛ teliya, nka nafa fana bɛ ye kɛnɛ kan. Ni welding frequency high-frequency bɛ kɛ ka nɛgɛ inox baara, ni debugging baarakɛlaw ka fɛɛrɛko dɔnniya ma kɛ nafolotigi ye, a ka c’a la kosɛbɛ ko perforation bɛna kɛ tuma caman na, ani ko fɛnw bɛna caya kosɛbɛ.

Laser welding .

Laser welding ye welding fɛɛrɛ ye min bɛ baara Kɛ ni funteni ye min bɛ Bɔ welda la ni laser-fiɲɛ ye min sinsinnen bɛ fanga sɔrɔyɔrɔ kan. K’a sababu Kɛ laser yeelen yecogo ye i n’a fɔ refraction ani focusing, laser welding bɛnnen don kosɛbɛ micro yɔrɔw ni yɔrɔw welding ma minnu sɔrɔli man ɲi. Laser welding fana bɛ ni funteni dɔgɔman doncogo ye, welding deformation misɛnninw, wa a tɛ nɔ bila kuran-yɔrɔw la nka, sisan, laser welding ma baara kɛ kosɛbɛ ni pipes welded inox foro la. kɛrɛnkɛrɛnnenya la, laserw sɔngɔ ka bon ani kuran-optiki caman tigɛli nafa ka bon. Olu la, masinw ni minɛnw don musaka ka bon, o ye gɛlɛya jɔnjɔn ye. Nka, a bɛ se ka fɔ ko laser welding bɛna kɛ yiriwali sira nata ye o baara in na. Laser welding pipe teliyaba min bɛ kɛ ka so kɔnɔ, o bɛ kɛ sababu ye ka fɛnw dilan. ye fana san Hangao Tech (Seko masinw) . laban ninnu na .