Mpɛn pii no, sanitary ne stainless steel pipe welding nhyehyɛe, a wɔde argon arc welding kwan di dwuma. Mprempren, adeyɛ a ɛho akokwaw sen biara a wɔde yɛ dade a ɛnyɛ den a wɔde weld ayɛ wɔ adwuma no mu no da so ara yɛ argon arc welding titiriw.

Tig Welding .

Stainless steel welded pipes hwehwɛ sɛ ɛkɔ mu kɔ akyiri, oxide biara nka ho, na ɛyɛ beae ketewaa bi a ɔhyew ka ho sɛnea ɛbɛyɛ yiye. Tungsten inert gas shielded argon arc welding wɔ adapability pa, welding a ɛkorɔn ne penetration adwumayɛ pa. Wɔde nea wɔyɛ no di dwuma kɛse wɔ nnuruyɛ mu. , Wɔde nuklea adwumayɛ ne nnuan ho nnwuma di dwuma kɛse.

Ansa na welding reba no, ɛsɛ sɛ wɔde gas tew nsu afiri no ho. Sɛ welding wie a, ɛsɛ sɛ wɔhwɛ welding joint no mu na wɔsɔ nhyɛso hwɛ, na afei wɔpopa nsu afiri no mprenu (wobetumi de nitrogen adi dwuma ama purge gas no), na afei wɔde nsu a ɛho tew ahyɛ nsu afiri no mu. Fa sodium hypochlorite aduru gu nsu a ɛho tew no mu, na sɛ wode nsu afiri no gu mu wie a, san hohoro nsu afiri no mu kosi sɛ sodium hypochlorite aduru biara renka nsu a ɛrehoro no ho. Dade a ɛnyɛ den a wɔde fa nsu mu no di amanaman ntam gyinapɛn ahorow a ɛfa dade a ɛnyɛ den a ɛho ntew ho, a mprempren ɛwɔ amannɔne no ho dwuma. Sanitary ne stainless steel pipes no dodow no ara yɛ sterilized denam ultraviolet rays so wɔ welding akyi, na argon arc welding da so ara fata ma welding. Wɔde dade a ɛnyɛ den di dwuma kɛse wɔ nnuan ho nneɛma mu (titiriw aduan ho ahotew a ɛyɛ dade a ɛnyɛ den a wɔde yɛ nsu a ɛnyɛ den), a emu dodow no ara yɛ dade a ɛnyɛ den a ɛyɛ austenitic, na nea wɔyɛ no yɛ nea wɔde welding kwan no wie kɛse.

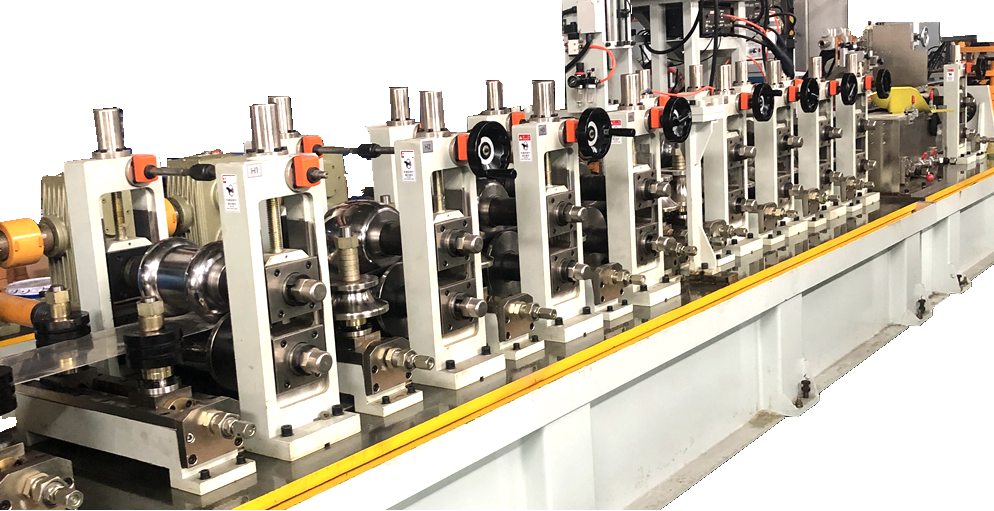

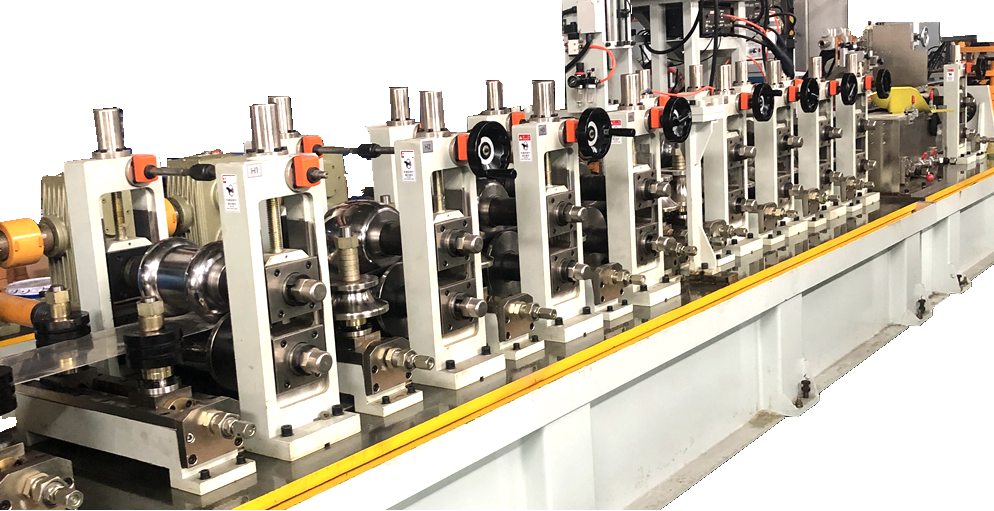

Welding a ɛwɔ frequency a ɛkorɔn .

Wɔde frequency welding a ɛkɔ soro adi dwuma wɔ carbon steel welded pipes a wɔyɛ mu bɛboro mfe 40, nanso dade a ɛnyɛ den a wɔde yɛ nsu afiri a wɔde yɛ welding a ɛnyɛ den a wɔde di dwuma no yɛ mfiridwuma foforo koraa. Sikasɛm a ɛwɔ ne yɛ mu no ma nea ɔyɛ no yɛ nea wɔde di dwuma kɛse wɔ adansi ho nneɛma a wɔde siesie hɔ, ofie nneɛma ne mfiri a wɔde yɛ nneɛma mu. Mfaso a ɛwɔ so ne sɛ ahoɔhare a wɔde yɛ nneɛma no yɛ ntɛmntɛm, nanso ɔhaw no nso da adi pefee. Sɛ wɔde frequency welding a ɛkorɔn di dwuma de yɛ stainless steel ho adwuma a, sɛ debugging adwumayɛfo no mfiridwuma mu osuahu no nyɛ adefo sɛnea ɛsɛ a, ɛda adi yiye sɛ ntokuru no bɛba mpɛn pii, na nneɛma a wɔde di dwuma no bɛkɔ soro kɛse.

Laser a wɔde yɛ welding .

Laser welding yɛ welding kwan a ɛde ɔhyew a ɛnam laser beam a wɔde wɔn adwene si so a wɔtow hyɛ weldment no so no di dwuma sɛ ahoɔden fibea. Esiane optical ahoɔden a laser hann te sɛ refraction ne focusing, laser welding fata yiye ma welding a micro afã horow ne afã horow a ɛnyɛ yiye accessibility. Laser welding nso wɔ su a ɛma ɔhyew a ɛba fam, welding deformation nketewa, na electromagnetic fields nnya so nkɛntɛnso nanso, mprempren, laser welding nni dwuma kɛse wɔ afuw a stainless steel welded pipes. Titiriw esiane bo a ɛkɔ soro a laser ne electro-optical nsakrae efficiency nti. Wɔn mu no, mfiri ne nnwinnade a wɔde hyɛ mu no ho ka kɛse ne ade titiriw a ɛmma wontumi nyɛ saa. Nanso, ɛyɛ nea wobetumi ahu sɛ laser welding bɛyɛ daakye nkɔso su a ɛbɛba wɔ nnwuma no mu. High-speed laser welding pipe yɛ afiri a wɔtɔn duct production line . no nso yɛ nea wɔde wɔn adwene si so Hangao Tech (seko mfiri) . wɔ nnansa yi mfe mu .