A tlangpuiin, sanitary leh stainless steel pipe welding process, argon arc welding hmanga siam a ni. Tunah hian industry-a stainless steel welded pipe siamna atana puitling ber chu argon arc welding a la ni ber.

Tig Welding tih a ni.

Stainless steel welded pipe-ah chuan penetration thuk tak, oxide inclusions awm lo, leh a theih ang anga heat-affected zone tenau tak a ngai a ni. Tungsten Inert Gas Shielded Argon Arc Welding hian adaptability tha tak a nei a, welding quality sang tak leh penetration performance tha tak a nei bawk. A thil siamte hi chemical industry-ah hman a ni nasa hle. , nuclear industry leh ei leh in lama industry te hi hman a ni nasa hle.

Weld hmain pipeline chu gas hmangin purge tur a ni. Welding zawhah welding joint chu enfiah a, pressure test tur a ni a, chutah chuan pipeline chu vawi hnih purge tur a ni (nitrogen chu purge gas atan hman theih a ni), chutah chuan pipeline chu tui thianghlim nen soak tur a ni. Tui thianghlim ah sodium hypochlorite solution dah la, pipeline i soak hnuah pipeline chu flush leh la, tui thianghlim takah sodium hypochlorite solution a awm loh thlengin. Chutianga welded stainless steel pipe te chuan international standards for sanitary stainless steel pipe te chu an tlin a, tunah hian ram pawnah an awm mek a ni. Sanitary leh stainless steel pipe hi welding hnuah ultraviolet rays hmanga sterilized a ni tlangpui a, argon arc welding hi welding atan a la tha hle. Stainless steel hi ei leh in hmanrua (a bik takin ei tur faina grade stainless steel pipe)-ah hman a ni nasa hle a, a tam zawk chu austenitic stainless steel a ni a, a siamna hi welding process hmanga tihfel a ni tam ber a ni.

High frequency welding a awm bawk.

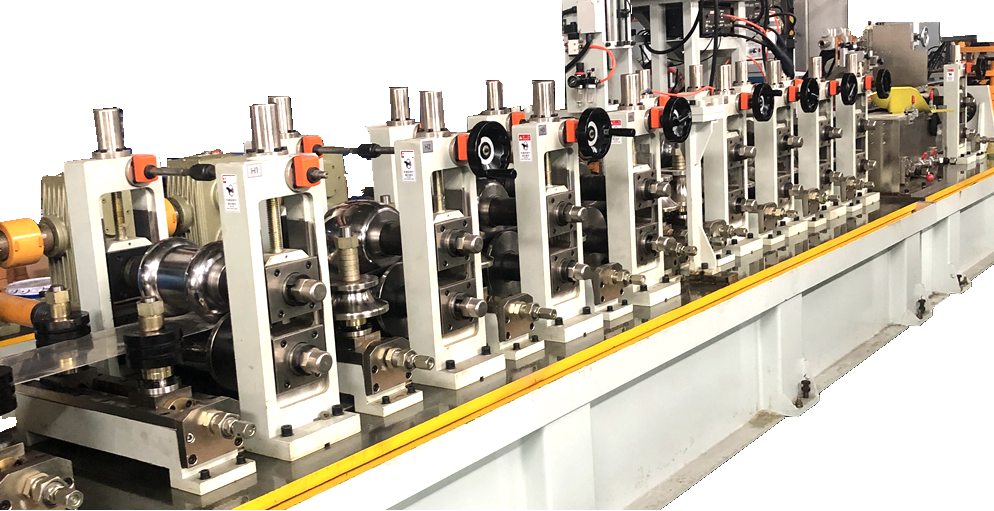

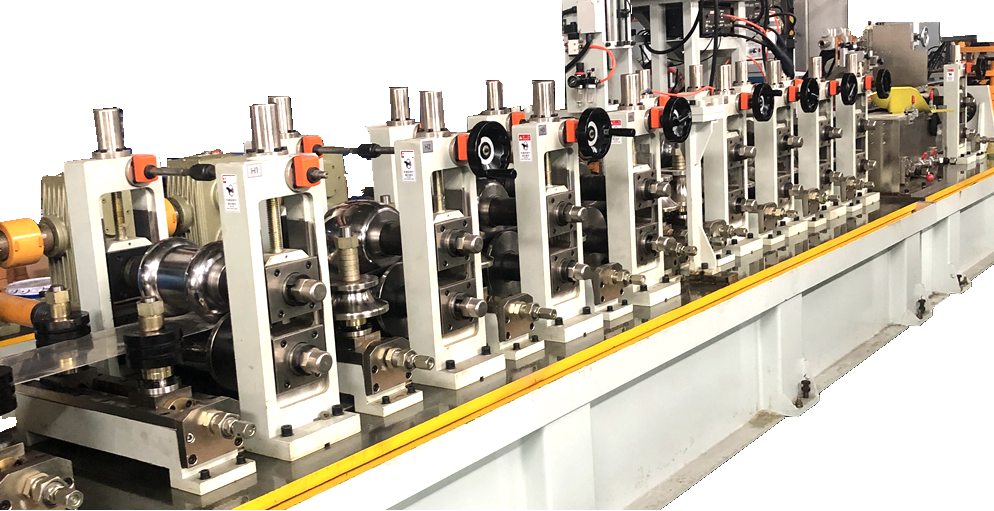

Kum 40 chuang zet carbon steel welded pipe siamnaah hian high-frequency welding hman a ni tawh a, mahse stainless steel pipe welding na atana sanitary stainless steel pipe hman hi technology thar tak a ni. A thil siam chhuahna economy chuan a thil siamte chu architectural decoration, inchhung bungrua leh mechanical structure-ah te hman a ni nasa zawk a ni. A thatna chu production speed a rang a, mahse a chhiatna pawh a chiang hle. High-frequency welding hi stainless steel process nan hman a nih chuan debugging personnel te technical experience a hausa tawk lo a nih chuan perforation a awm fo a rinawm hle a, consumables pawh nasa takin a pung ang.

Laser welding a awm em?

Laser welding hi welding method a ni a, weldment chu energy source atan focused laser beam hmanga bombarding atanga heat lo chhuak chu a hmang a ni. Laser light refraction leh focusing ang chi optical property avang hian laser welding hi micro parts welding atan a tha hle a, parts accessibility tha lo tak tak a awm bawk. Laser welding hian low heat input, welding small deformation ziarang a nei bawk a, electromagnetic field-in a nghawng lo nain, tunah chuan laser welding hi stainless steel welded pipe field-ah hman a ni lo hle. A chhan ber chu laser man sang leh electro-optical conversion efficiency hniam vang a ni. Chumi zingah chuan machinery leh hmanrua input cost sang tak chu key constraint factor a ni. Mahse, laser welding hi nakin lawka industry hmasawnna tur a nih tur thu a sawi. tih pawh hi A rilru a buai em em a, a rilru a hah em em bawk a, a rilru a buai em em bawk a. duct duct production line ngaih pawimawh ber a ni . hangao tech (Seko Machinery) tih a ni a. tun hnaia