Zi geɖe la, dzadzɛnyenye kple gakpo si mexɔ dzo o ƒe pɔmpi welding ƒe ɖoɖo, zãa argon arc welding mɔnu. Fifia la, mɔnu si tsi wu na gakpo si mexɔ dzo o si wotsɔ ga wɔe le dɔwɔƒea la gakpɔtɔ nye argon arc welding koŋ.

TIG ƒe Welding .

Pɔmpi siwo wotsɔ gakpo si mexɔ dzo o wɔ la hiã be woage ɖe eme goglo, womagade oxide ɖe eme o, eye wòanye teƒe sue aɖe si dzoxɔxɔa gblẽ nu le alesi woate ŋui. Tungsten inert gas akpoxɔnu argon arc welding le nyuie be wòatrɔ ɖe nɔnɔmewo ŋu, kɔkɔ welding nyonyome kple nyui penetration dɔwɔwɔ. Wozãa eƒe nutovɛwo le atikewɔƒewo le afisiafi. , Wozãa nuklia dɔwɔƒewo kple nuɖuɖudɔwɔƒewo le teƒe geɖe.

Hafi woatsɔ gas akɔ pɔmpia me la, ele be woatsɔ gas akɔ pɔmpia me. Ne wowɔ welding vɔ la, ele be woalé ŋku ɖe welding joint la ŋu ahado nyaƒoɖeamenu kpɔ, eye emegbe woakɔ pɔmpia ŋu zi eve (woate ŋu azã nitrogen na gas si wotsɔna kɔa nu ŋu), eye emegbe woatsɔ tsi dzadzɛ ade pɔmpia me. Tsɔ sodium hypochlorite solution de tsi dzadzɛa me, eye ne ède pɔmpia me vɔ la, gakɔ pɔmpia me vaseɖe esime sodium hypochlorite solution aɖeke naganɔ tsi si le tsia me la me o. Ga si mexɔ dzo o ƒe pɔmpi siwo wotsɔ ƒo ƒu to mɔ sia dzi la ɖoa dukɔwo dome dzidzenu siwo wozãna na gakpo siwo mexɔ dzo o siwo le dzadzɛnyenye me, siwo le duta fifia la gbɔ. Wotsɔa ultraviolet rays wɔa atike na dzadzɛnyenye kple gakpo si mexɔ dzo o ƒe pɔmpiwo ƒe akpa gãtɔ le welding megbe, eye argon arc welding gakpɔtɔ sɔ na welding. Wozãa gakpo si mexɔ dzo o le nuɖuɖudɔwɔnuwo me le afisiafi (vevietɔ nuɖuɖu ƒe dzadzɛnyenye ƒe ɖoɖo si wotsɔ gakpo si mexɔ dzo o ƒe pɔmpiwo wɔe), siwo ƒe akpa gãtɔ nye austenitic gakpo si mexɔ dzo o, eye wowua wo wɔwɔ nu akpa gãtɔ to welding wɔwɔ me.

WELDING si wozãna zi gbɔ zi geɖe .

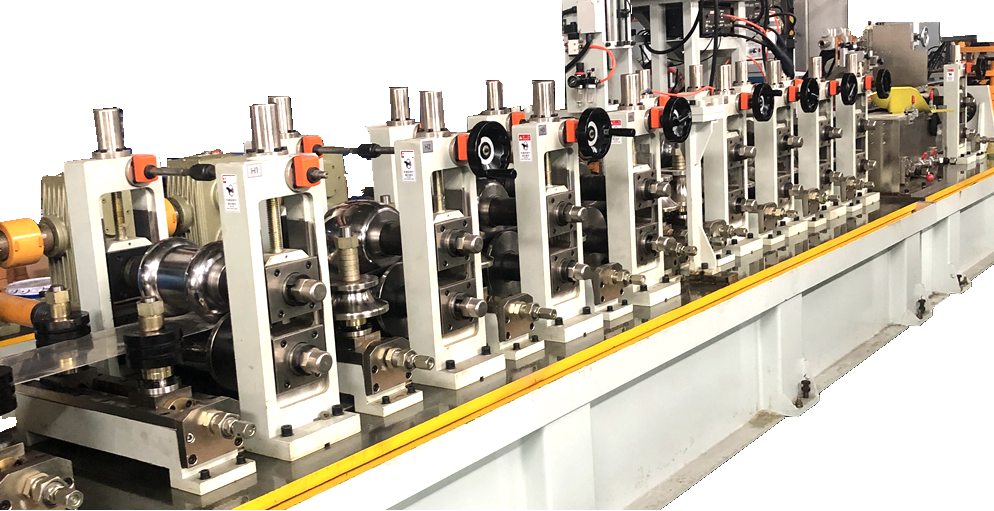

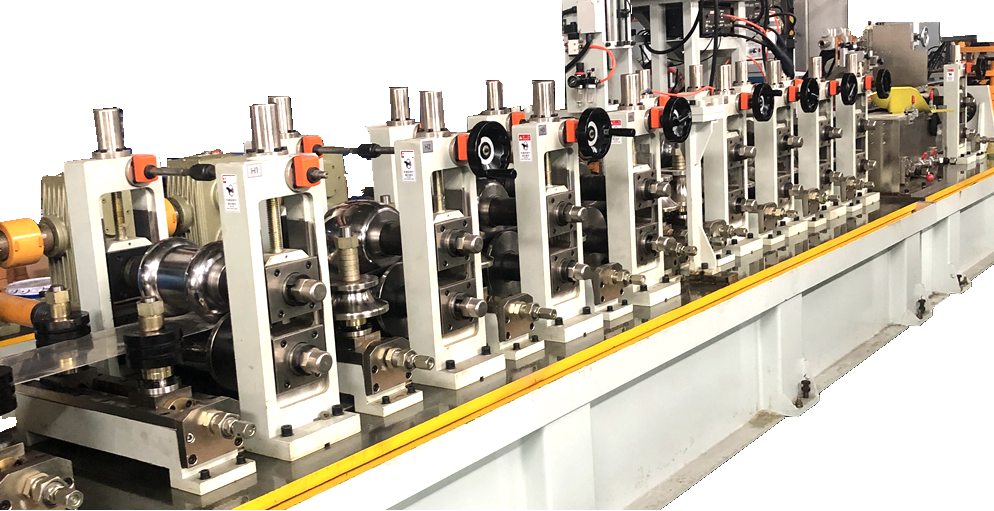

Wozãa ʋuƒo siwo wotsɔna ƒoa gae zi geɖe le pɔmpi siwo wotsɔa ga wɔe siwo wotsɔa ga wɔe la wɔwɔ me ƒe 40 kple edzivɔe nye sia, gake gakpo siwo mexɔ dzo o ƒe pɔmpiwo zazã na gakpo siwo mexɔ dzo o ƒe pɔmpiwo nye mɔ̃ɖaŋununya yeye aɖe ŋutɔ. Ewɔwɔ ƒe ganyawo na be wozãa eƒe nutovɛwo geɖe wu le xɔtuɖaŋu ƒe atsyɔ̃ɖoɖo, aƒemenuzazãwo kple mɔ̃ɖaŋunuwo ƒe akpawo me. Viɖe si le eŋue nye be nuwɔwɔ ƒe duƒuƒu le kabakaba, gake nusi gblẽ le eŋu hã dze ƒã. Ne wozã welding si ƒe tsɔtsɔme de ŋgɔ tsɔ wɔ dɔ tso gakpo si mexɔ dzo o ŋu la, ne mɔ̃ɖaŋununya ƒe nuteƒekpɔkpɔ si le debugging dɔwɔlawo me menye kesinɔtɔ o la, anɔ eme ŋutɔ be perforation adzɔ enuenu, eye woadzi nuzazãwo ɖe edzi ŋutɔ.

Laser Welding .

Laser welding nye welding mɔnu si zãa dzoxɔxɔ si dona tso bɔmbdada ɖe weldment la me kple laser beam si wotu ɖe edzi abe ŋusẽtsoƒe ene. Le laser kekeli ƒe nukpɔkpɔ ƒe nɔnɔmewo abe refraction kple focusing ene ta la, laser welding sɔ ŋutɔ na welding of micro parts and parts with lous accessibility. Laser welding hã ƒe nɔnɔmewo le dzoxɔxɔ sue aɖe ƒe gege ɖe eme, small welding deformation, eye mekpɔ ŋusẽ ɖe electromagnetic fields dzi gake, fifia la, laser welding mewɔ dɔ geɖe le agble me gakpo si mexɔ dzo o welded pɔmpiwo. Vevietɔ le laser ƒe asi kɔkɔ kple electro-optical ƒe tɔtrɔ ƒe ŋutete si le bɔbɔe ta. Le wo dome la, mɔ̃wo kple dɔwɔnuwo ƒe ga gbogbo si wotsɔ dea emee nye nu vevitɔ si xea mɔ na wo. Ke hã, woate ŋu akpɔe do ŋgɔ be laser welding anye etsɔme ŋgɔyiyi ƒe nɔnɔme le dɔwɔƒea. High-speed laser welding pɔmpi wɔwɔ mɔ̃ na dzadzra duct wɔwɔ fli . nye nusi ŋu woƒo nu tsoe Hangao Tech (Seko Mɔ̃wo) le ƒe ʋɛ siwo va yi me hã .