Generally, sanitary and stainless steel pipe welding process, using argon arc welding method. At present, the most mature process for stainless steel welded pipes in the industry is still mainly argon arc welding.

TIG welding

Stainless steel welded pipes require deep penetration, no oxide inclusions, and as small a heat-affected zone as possible. Tungsten inert gas shielded argon arc welding has good adaptability, high welding quality and good penetration performance. Its products are widely used in chemical industry. , nuclear industry and food industries are widely used.

Before welding, the pipeline should be purged with gas. After welding, the welding joint should be inspected and pressure tested, and then the pipeline should be purged twice (nitrogen can be used for the purge gas), and then soak the pipeline with clean water. Add sodium hypochlorite solution to the clean water, and after soaking the pipeline, flush the pipeline again until no sodium hypochlorite solution remains in the flushing water. The stainless steel pipes welded in this way meet the international standards for sanitary stainless steel pipes, which are currently abroad. Sanitary and stainless steel pipes are mostly sterilized by ultraviolet rays after welding, and argon arc welding is still suitable for welding. Stainless steel is widely used in food equipment (especially food hygiene grade stainless steel pipes), most of which are austenitic stainless steel, and its manufacture is largely completed by welding process.

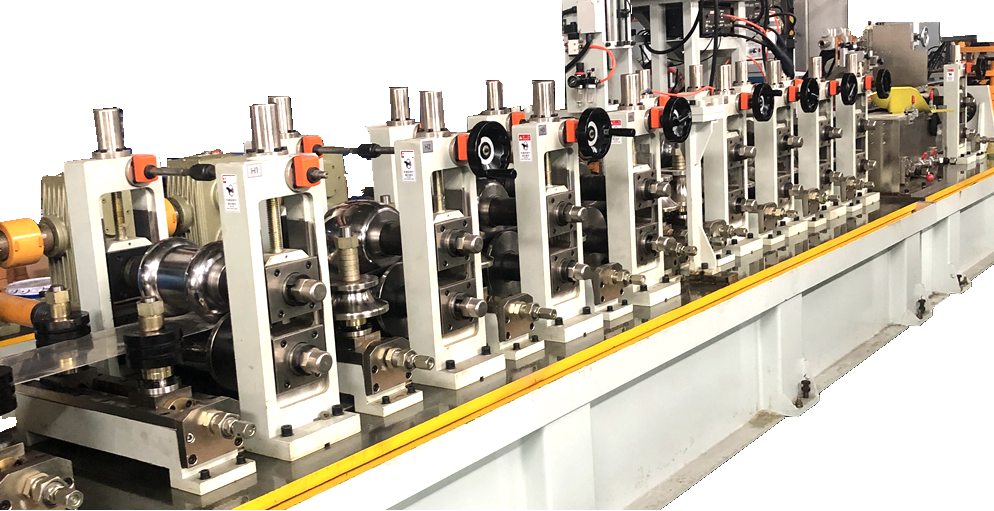

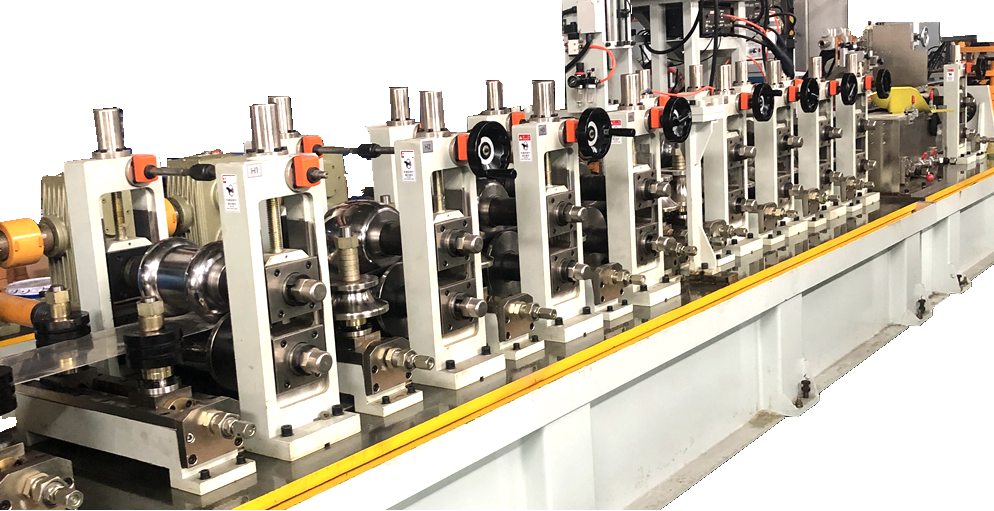

High Frequency Welding

High-frequency welding has been used in the production of carbon steel welded pipes for more than 40 years, but the use of sanitary stainless steel pipes for welding stainless steel pipes is a relatively new technology. The economy of its production makes its products more widely used in the fields of architectural decoration, household appliances and mechanical structures. Its advantage is that the production speed is fast, but the disadvantage is also obvious. When high-frequency welding is used to process stainless steel, if the technical experience of the debugging personnel is not rich enough, it is very likely that perforation will occur frequently, and the consumables will be greatly increased.

Laser welding

Laser welding is a welding method that uses the heat generated by bombarding the weldment with a focused laser beam as an energy source. Due to the optical properties of laser light such as refraction and focusing, laser welding is very suitable for the welding of micro parts and parts with poor accessibility. Laser welding also has the characteristics of low heat input, small welding deformation, and is not affected by electromagnetic fields However, at present, laser welding has not been widely used in the field of stainless steel welded pipes. Mainly due to the high price of lasers and low electro-optical conversion efficiency. Among them, the high input cost of machinery and equipment is the key constraint factor. However, it is foreseeable that laser welding will be the future development trend of the industry. High-speed laser welding pipe making machine for sale duct production line is also the focus of Hangao Tech (SEKO Machinery) in recent years