Tunah hian stainless steel pipe hi market-ah an hmang nasa hle a, industry tam takah pawh hmun pawimawh tak an chang a ni.

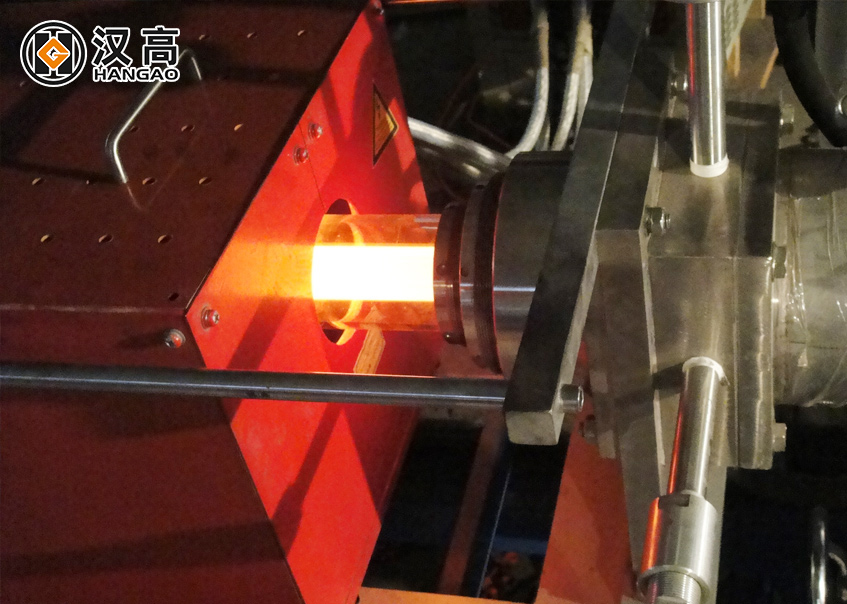

Stainless steel pipe annealing principle chu:

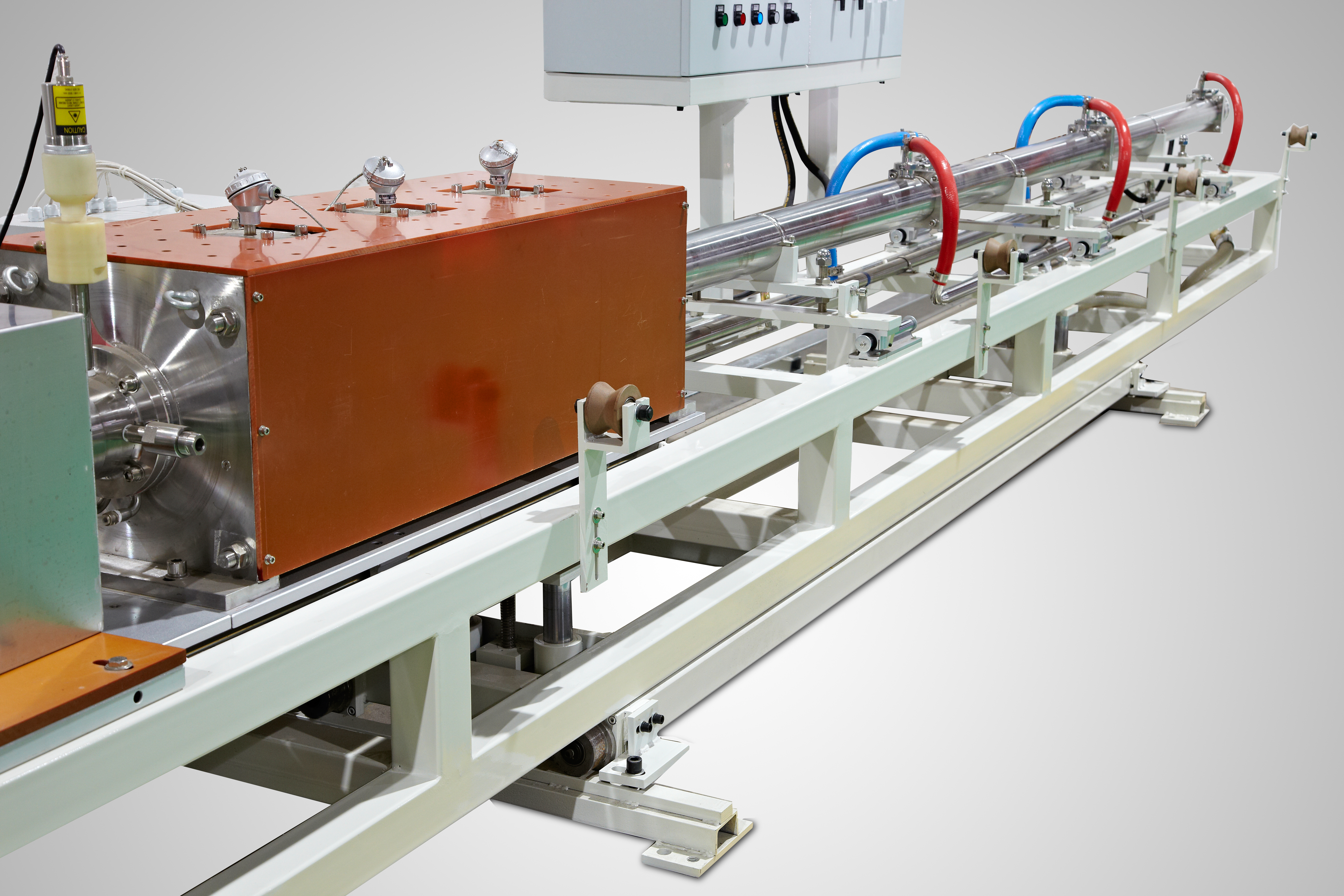

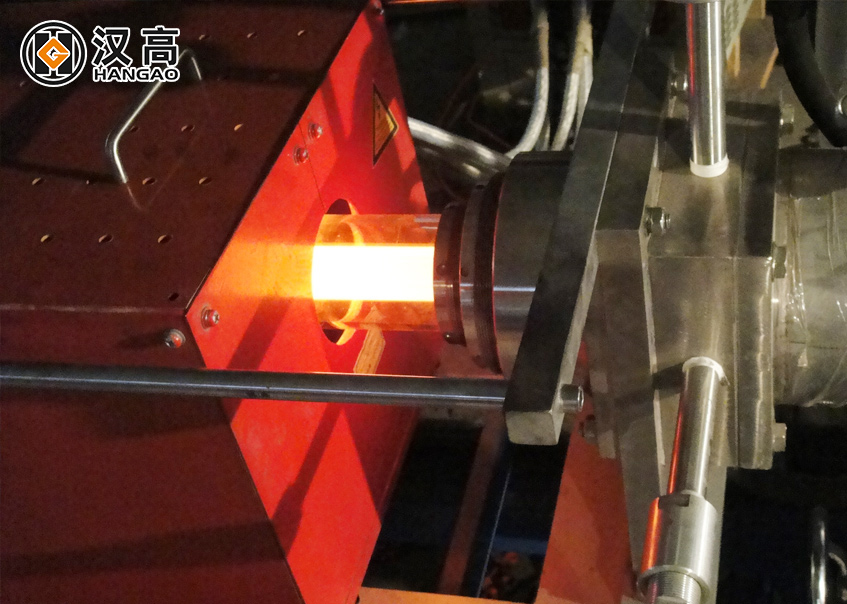

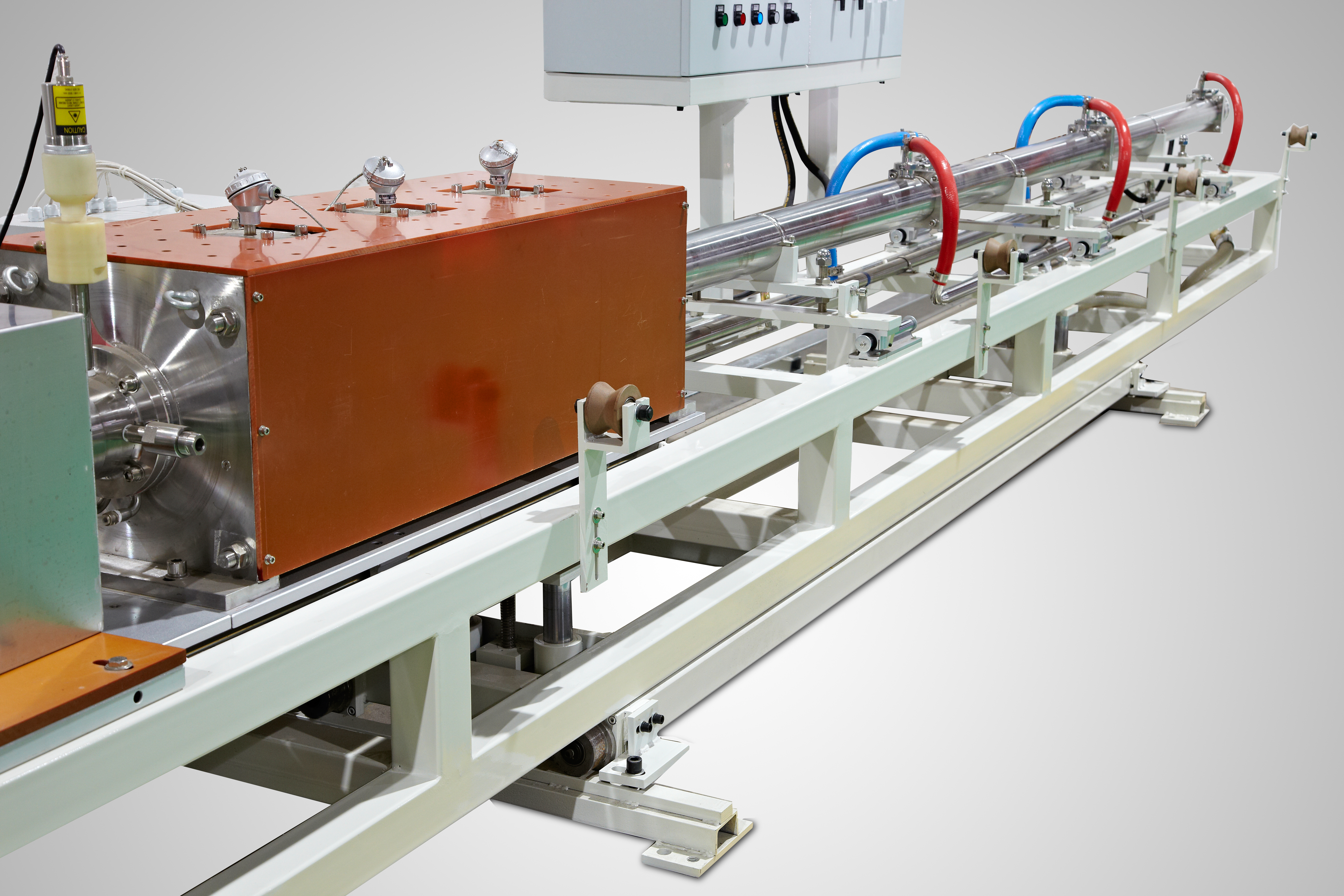

Stainless steel pipe-te hnathawh harsa tak chu tihbo a nih chuan metallographic structure lungawithlak tak hmuh theih a ni. Annealing equipment hi stainless steel continuous bright annealing furnace a ni a, hei hi a bik takin stainless steel siam zawh tawh, venhimna boruak hnuaia heat treatment atan hman a ni. Stainless steel pipe-a application performance mamawh a danglam chuan bright annealing hnua metallographic structure atana mamawh a danglam avangin bright heat treatment process pawh a danglam dawn a ni. 300 series austenitic stainless steel hmanga heat treatment kalpui dan tlangpui chu solution treatment a ni. Heating process chhung hian carbides te chu austenitic stainless steel ah an inthiar a, 1050~1150°C ah an dah a, chutah chuan hun rei lo te chhung an lum a. Carbide zawng zawng chu austenite structure-ah a hmin vek thei a, chutah chuan rang takin 350°C hnuaiah a lum thei bawk. Supersaturated solid solution an hmu a, chu chu unidirectional austenite structure inang tlang tak a ni. He heat treatment process-a kan ngaih pawimawh ber chu cooling rang tak a ni a, chu chuan cooling rate chu 55°C a thlen a ngai a, chutah chuan carbide solid solution hnuah re-precipitation temperature zone (550~850°C) chu rang takin a paltlang a ngai a ni. Chu bakah, stainless steel pipe-te heat preservation time chu a tawi thei ang berah a awm tur a ni a, chuti lo chuan particle te chu a coarse ang a, surface finish a nghawng ang.

400 series ferritic stainless steel-a heating temperature hi a hniam hle (900°C vel), a tam zawkah chuan slow cooling hmangin annealed leh softened structure an hmu thei a ni. Martensitic stainless steel atana hman thin annealing method pawh hi segmented fire hmangin a enkawl theih a, chu chu tempering a ni bawk. A chunga kan sawi tak atang hian 300 series leh 400 series inkar ah hian heat treatment processing technology ah hian danglamna lian tak a awm tih kan hre thei. Metallographic structure thiam tak neih theih nan chuan annealing furnace eng tak cooling section hmanrua chuan adjustment room lian tak a mamawh a ni. Chuvangin, tuna advanced bright annealing furnace-ah hian an cooling section-ah convection cooling chak tak an hmang fo a, cooling section pathum an nei bawk.

Stainless steel pipe annealing an tih chhan:

1. Hardness tihziaawmna leh plasticity tihchangtlun nan cutting leh cold deformation processing awlsam zawk nan.

2. Grains te chu tithianghlim la, steel structural composition uniform la, steel hnathawh that emaw, a hnua heat treatment atana inbuatsaih emaw.

3. Deformation leh cracking awm loh nan steel-ah hian residual internal stress tihbo.

Mahse, mi tam tak chuan annealed stainless steel pipe chu yellow emaw blue emaw a lo ni a, beisei ang bright effect a neih theih loh phah fo thin niin an sawi. Chuvangin engtin nge he harsatna hi kan chinfel theih ang?

Tunah chuan, engineer-te chuan . HAGAO Machinery chuan a sawipui ang che:

1. Unstable heating temperature vang pawh a ni thei. Pipe a lum chuan a chung lam temperature a sang a, mahse a chhung lam temperature a hniam thung. Annealing temperature control emaw, annealing furnace-a temperature zone division design-na emaw avanga harsatna awm vang pawh a ni thei. Tunah chuan market-ah hian annealing furnace chi hrang hrang a awm a, a man pawh a inang lo hle a, a hmangtute tan thil tha leh tha lo thliar hran a harsa hle.

2. Process flow leh technology atang hian a chhan zawng la, chu chu a hmangtu temperature setting, stainless steel pipe a surface cleanliness leh stainless steel pipe material te nen a inzawm a ni.

A chunga harsatna kan tawhte chinfel a, annealing hnua stainless steel pipe eng siam nan chuan a hnuaia thil tih tur pawimawh ber berte chu a ni:

1. Heating furnace body leh cooling section boruak tightness hi stainless steel pipe a eng em tih chhan pawimawh tak a ni.

2. Annealing furnace structure, temperature zone insem dan, leh annealing furnace thermal field te hi a dik em tih te. Heng thilte hian stainless steel pipe lumna chu direct-in a nghawng a ni.

Uniformity, stainless steel pipe chu incandescent state-ah a lum tur a ni a, mahse pipe body lum chu a nem leh a hnim tur a ni lo. Heating temperature sang lutuk hian pipe chhunga structure siam that lehna atan a tha lo.

3. Stainless steel pipe ngei pawh hian oil emaw tui emaw a tam lutuk chuan furnace chhunga venhimna boruak chu a chhe vek ang a, a venna gas thianghlimna pawh a thleng lo ang. Stains emaw water vapor emaw chuan pipe body chunglamah a innghat ang a, a smoothness a nghawng ang. Hetih lai hian thil pawimawh tak takte faina leh cooling water pipe-a leakage a awm leh awm loh kan enfiah thei a, pakhat hnu pakhatin kan chhui thei bawk.

4. Thli chu furnace chhungah a luh leh loh nan furnace chhunga boruakah pressure tlem te te ensure tur a ni. Ammonia decomposition mixed gas a nih chuan 20kbar aia tam a mamawh tlangpui.

He hriatna leh thlirletna hian a puih theih che ka beisei. 1999 chungchanga zawhna emaw mamawh emaw a awm chuan. Steel Pipe Induction Annealing Furnace , min rawn biak theih reng e.