Kungani ishubhu lensimbi engagqwali liphenduka liphuzi noma limnyama ngemuva kokuphikisana okukhanyayo?

Ukubukwa: 156 Umlobi: Isikhathi Sokushicilela i-IRIS: 2024-05-23 ORIGID: Hangao (seko)

Buza

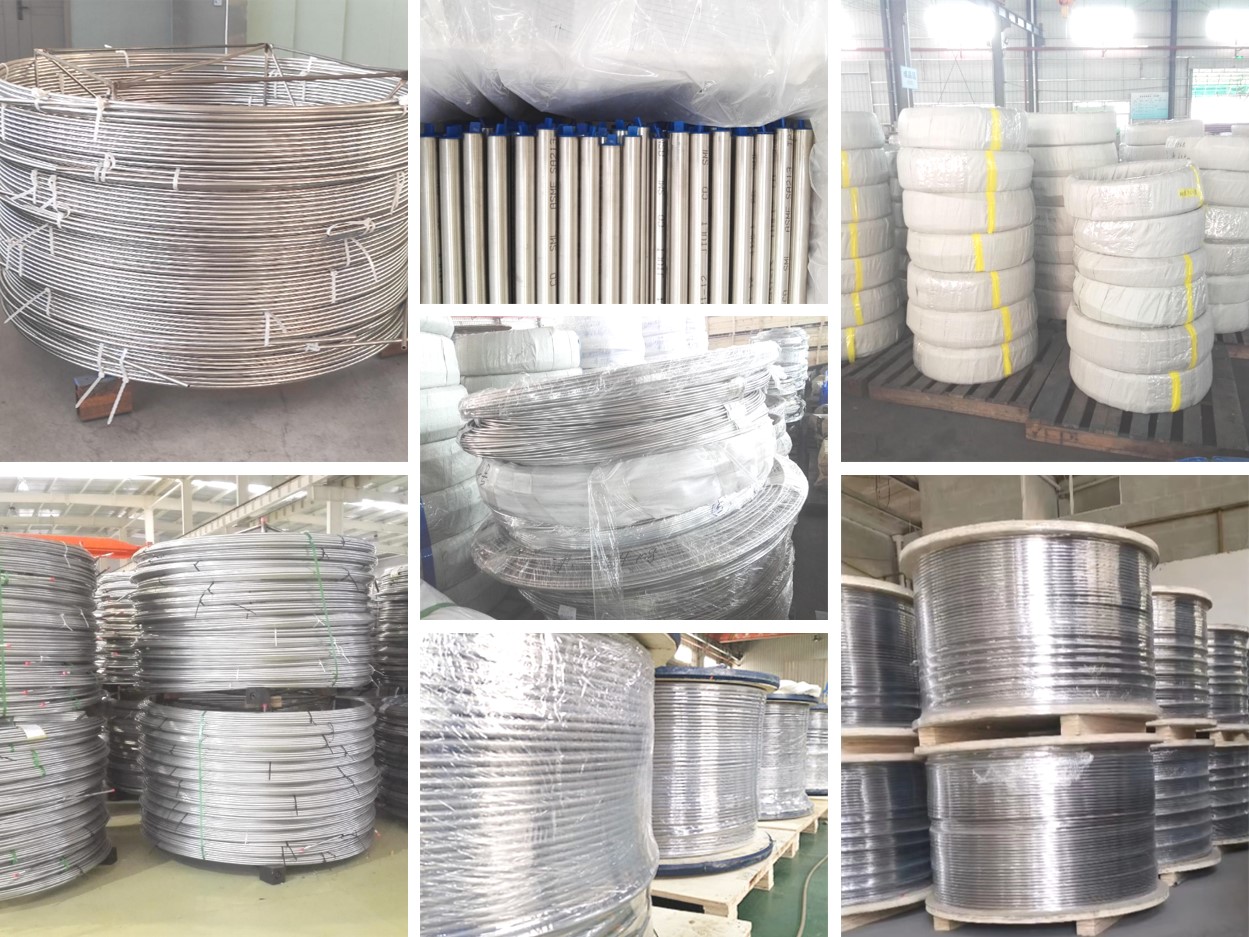

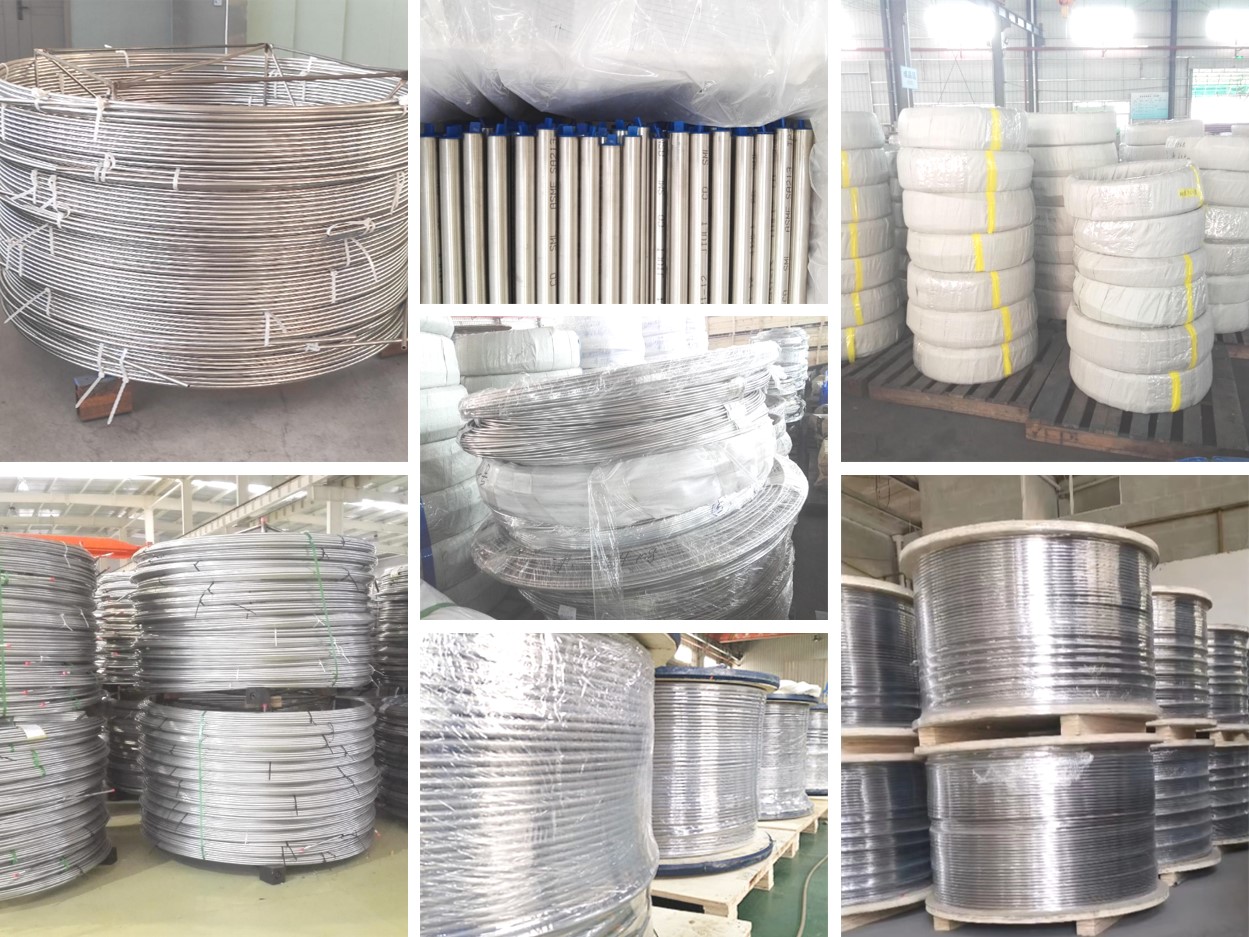

Njengamanje, amapayipi ensimbi angenasici asetshenziswa kabanzi emakethe, futhi adlala indima ebaluleke kakhulu ezimbonini eziningi.

Umgomo wokufaka amapayipi ensimbi engagqwali:

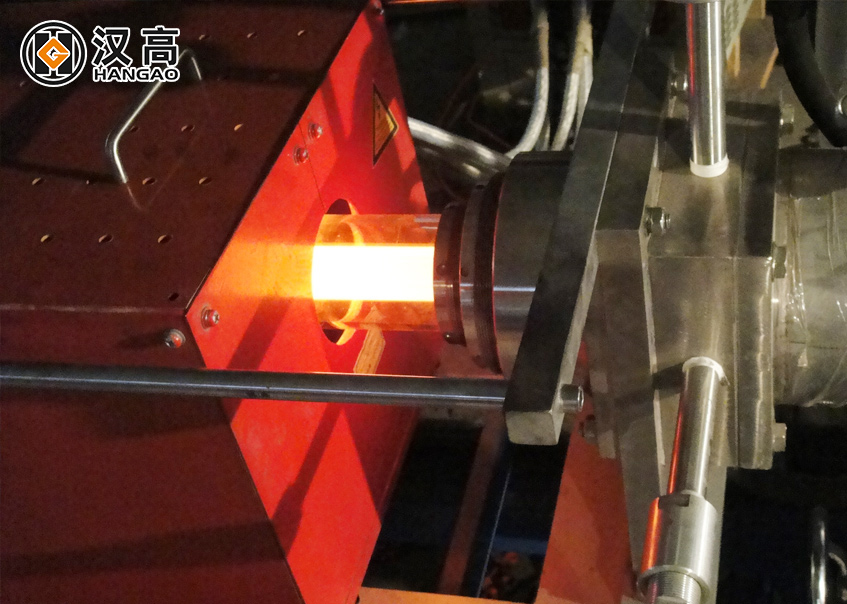

Isakhiwo se-metallographic agculisayo singatholakala ngokuqeda umsebenzi wokuqina kwamapayipi ensimbi engagqwali. Imishini yokungenisa i-annealing insimbi engenasici eqhubekayo yokuvuselela isithando, esisetshenziselwa ukwelashwa okushisa kwemikhiqizo yensimbi engenasici ngaphansi komoya wokuvikela. Lapho izidingo zokusebenza kohlelo lokusebenza zamapayipi ensimbi ezingagqwali zihlukile, izidingo zesakhiwo se-metallographic ngemuva kokuvela okukhanyayo, ngakho-ke inqubo yokwelashwa okukhanyayo nayo izokwehluka. Inqubo ejwayelekile yokwelashwa kokushisa kochungechunge lwe-300 cherch auntenitic insimbi engenacala ukwelashwa kwesisombululo. Ngesikhathi senqubo yokushisa, ama-carbides ancibilika ngensimbi e-auntenitic engenasici, afudunyezwe ku-1050 ~ 1150 ℃, bese eqhubeka efudumele isikhashana. Zonke izimoto ze-carbides zingachithwa esakhiweni se-aucenite, bese zisheshe ziphonswe ngaphansi kwama-350 ℃. Isixazululo esiqinile esinamandla siyatholakala, okuyinto eyunifomu ye-autenite yesakhiwo se-aucenite. Ukugxila kwale nqubo yokwelashwa kokushisa kupholisa ngokushesha, okudinga ukuthi izinga lokupholisa lifinyelele ku-55 ° C, bese lidlula ngokushesha endaweni yokushisa ye-re-prepitation (550 ~ 850 ° C) ngemuva kwesixazululo esiqinile se-Carbide Cer. Ngaphezu kwalokho, isikhathi sokulondolozwa kokushisa kwamapayipi ensimbi esingenasici kufanele kube mfushane ngangokunokwenzeka, uma kungenjalo izinhlayiya zizoba ziboshwe futhi zithinte ukuqeda komhlaba.

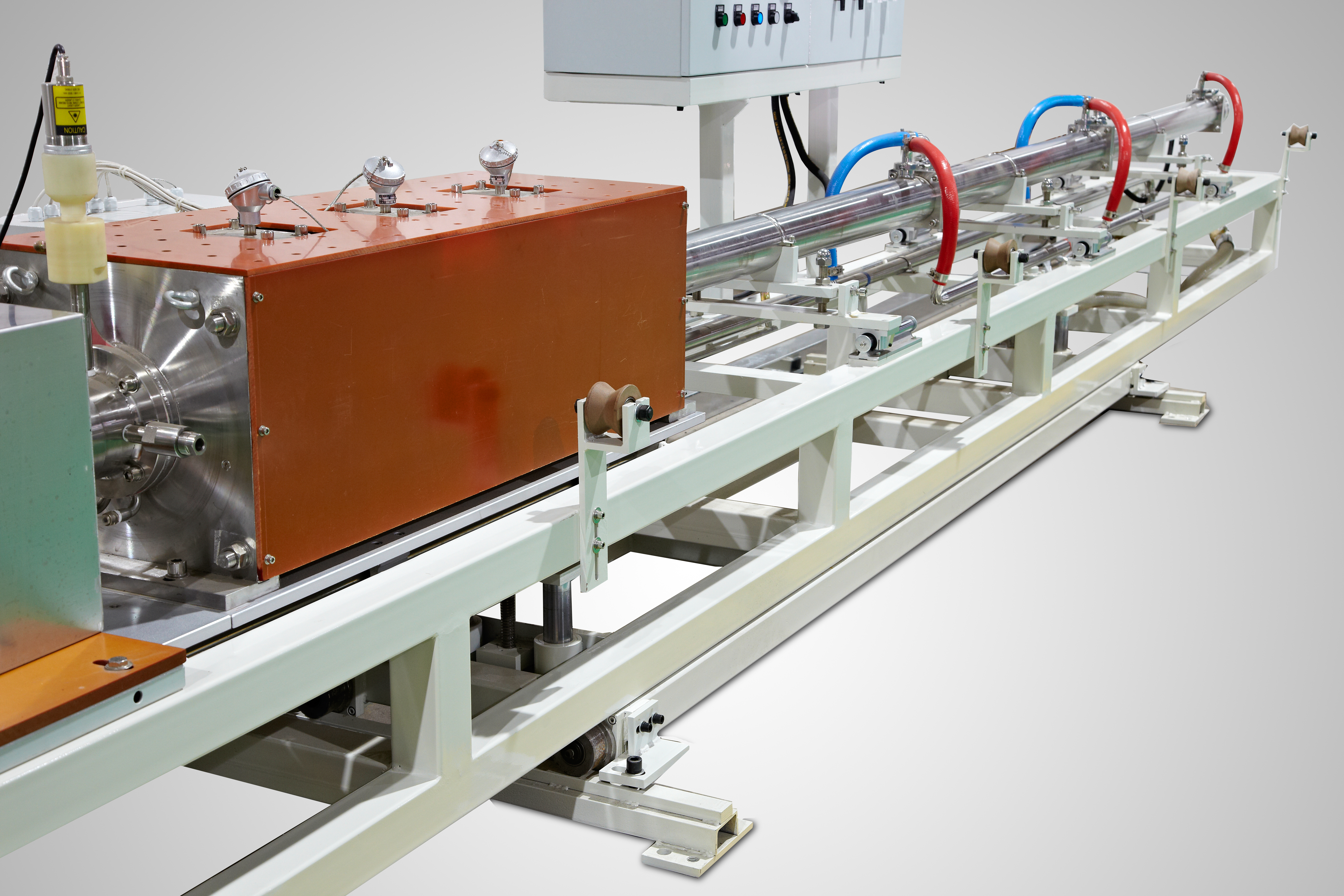

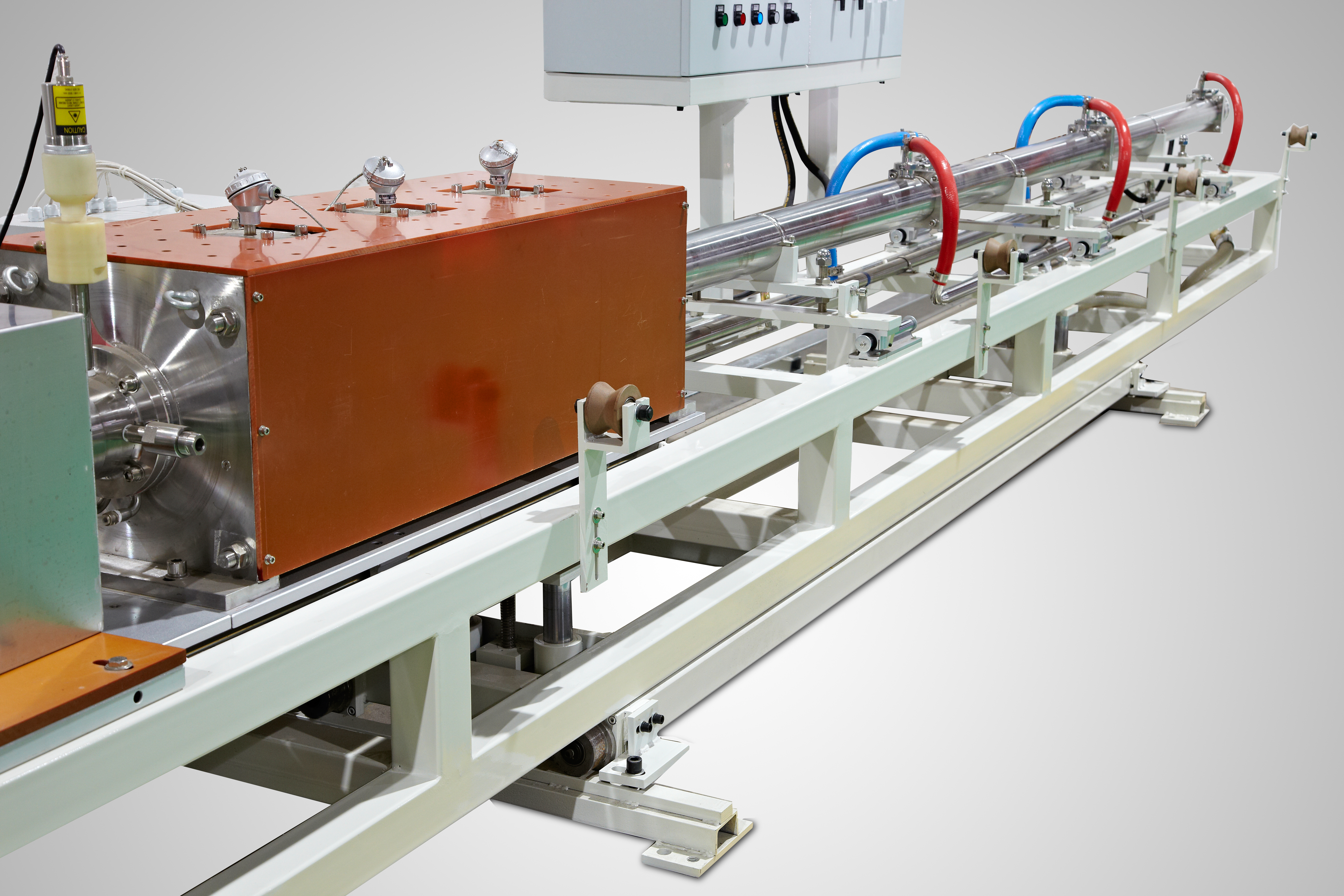

Izinga lokushisa lokushisa likachungechunge lwe-400 lwensimbi engenacala liphansi (cishe ngo-900 ° C), futhi ngezinga elikhulu, ukupholisa kancane kusetshenziselwa ukuthola isakhiwo esinempilo nesithambile. Indlela yokungenisa i-Annealing esetshenziselwa insimbi engenacala engagqwali ingalashwa ngomlilo ohlukanisiwe bese usula. Ukusuka kwesingeniso esingenhla, singazi ukuthi kunomehluko omkhulu kubuchwepheshe bokucubungula ukwelashwa okushisa phakathi kochungechunge 300 nochungechunge lwama-400. Ukuze uthole isakhiwo se-metallographic esiqeqeshiwe, imishini yokupholisa yesigaba sesithando esikhanyayo idinga igumbi elikhulu lokulungiswa. Ngakho-ke, izimfanelo zamanje ezithuthukile ezithuthukile zivame ukusebenzisa ukupholisa okuqinile kwezingxenye zabo zokupholisa, futhi zihlome ngezigaba ezintathu zokupholisa.

Inhloso yokufaka amapayipi ensimbi engagqwali:

1. Yehlisa ubulukhuni futhi uthuthukise i-plasticity ukwenza lula ukusika nokusebenza okubandayo kokukhubazeka.

2. Hlaziya okusanhlamvu, ukufana nokwakheka kwensimbi, ukuthuthukisa ukusebenza kwensimbi noma ukulungiselela ukwelashwa okushisa okulandelayo.

3. Susa ukucindezelwa kwangaphakathi okusele ngensimbi ukuvikela ukonakala nokuqhekeka.

Kodwa-ke, abasebenzisi abaningi babika ukuthi ipayipi lensimbi elingagqwali liphenduka liphuzi noma aluhlaza okwesibhakabhaka futhi lihlala lihluleka ukufeza umphumela okhanyayo okhanyayo. Ngakho-ke ungaxazulula kanjani le nkinga?

Manje, onjiniyela abavela Imishini ye-Hangaya izodingida nawe:

1. Kungabangelwa izinga lokushisa lokushisa elingazinzile. Lapho ipayipi lifudumele, izinga lokushisa elingaphezulu liphezulu kepha izinga lokushisa elingaphakathi liphansi. Kungabangelwa yizinkinga ngokulawula okushisa kokushisa noma ukwakhiwa kwesigaba sokushisa sokushisa kwesithando se-annelling. Kulezi zinsuku, kunezinhlobo eziningi zezinto zokufaka izithambiso emakethe, futhi amanani entengo ahluka kakhulu, okwenza kube nzima kubasebenzisi ukuhlukanisa okuhle kokubi.

2. Thola imbangela evela ku-Flow Flow and Technology, okuhlobene nokushisa komsebenzisi kokushisa komsebenzisi, ukuhlanzeka komhlaba wepayipi lensimbi engenasici, kanye nokuqukethwe kwepayipi lensimbi engagqwali.

Ukuze uxazulule izinkinga ezingenhla futhi wenze ipayipi lensimbi elingagqwali likhanye ngemuva kokuncibilikisa, okulandelayo kuyizinto eziphambili okufanele zenziwe:

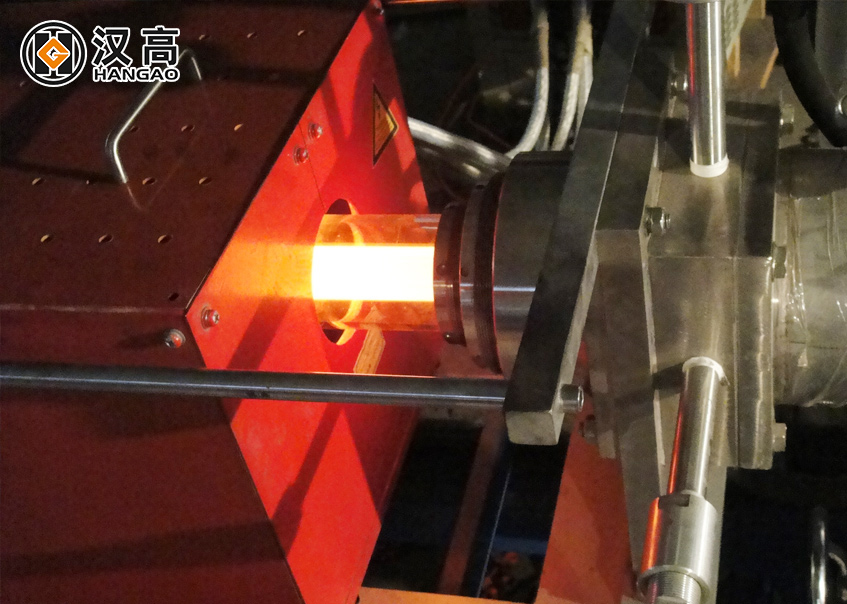

1. Ukuqina komoya komzimba weFuraring Full and Cooding Isici esiyisihluthulelo sokuthi ipayipi lensimbi elingagqwali likhanya.

2. Ukuthi ukwakheka kwesithando somlilo, ukusatshalaliswa kwendawo yokushisa, futhi insimu eshisayo yesithando somlilo inengqondo. Lezi zinto zithinta ngqo ukufudumala kwamapayipi ensimbi engagqwali.

Ukufana, ipayipi lensimbi engenasici kumele lifudunyezwe esimweni se-incandescent, kepha umzimba wepayipi ovuthayo akufanele uthambise futhi uthambile. Ukushisa izinga lokushisa eliphakeme kakhulu akukubi nokubuyisela ukwakheka kwangaphakathi kwepayipi.

3. Uma ipayipi lensimbi elingagqwali ngokwalo linamabala amaningi kakhulu noma amanzi, isimo esivikela esithandweni somlilo siyobhujiswa futhi ubumsulwa begesi evikelayo ngeke bufinyelelwe. Amabala noma umphunga wamanzi uzonamathela ebusweni bomzimba wepayipi futhi athinte ubushelelezi. Ngalesi sikhathi, singabheka ukuhlanzeka kwezinto ezibalulekile nokuthi ngabe kukhona ukuvuza emapayipi amanzi apholile, futhi azophenya ngawo.

4. Qinisekisa ingcindezi emncane emkhathini osesithandweni sokuthi umoya ungasuswa esithandweni somlilo. Uma kungukuvunyelwa kwe-ammonia ukubola igesi ehlanganisiwe, kuvame ukudinga ngaphezu kwe-20kbar.

Ngiyethemba lolu lwazi nokuhlaziywa kungakusiza. Uma kukhona imibuzo noma izidingo mayelana Insimbi yokungeniswa kwepayipi lokungeniswa kwensimbi , sicela ukhululeke ukuxhumana nathi.