Pibiliki minnu bɛ sɔgɔ ni nɛgɛ ye, olu ka funteni furakɛli kun ye ka funteni tolen ye: kelen ye ka degun tolenw bɔ yen minnu bɛ sɔrɔ nɛnɛ baara nɛnɛ waati la, n’o ye ka nɛgɛbere sɔgɔli kɛ ka kɛ tubu ye ani sɔgɔli kɛcogo la O ye wale nafama ye walasa ka pipe weldalenw ka baara kɛcogo sabati ka se solide solide ma ka kɛ ɔsitɛni ye ani ka sɔrɔ ka teliya ka nɛnɛ walasa ka ɔsitɛni bali ka sanji walima fasa caman wuli nɛnɛ waati la.

Fɛn minnu bɛ nɔ bila funteni furakɛli la ɛntɛrinɛti kan .

1. Funteni furakɛli funteni nɔ .

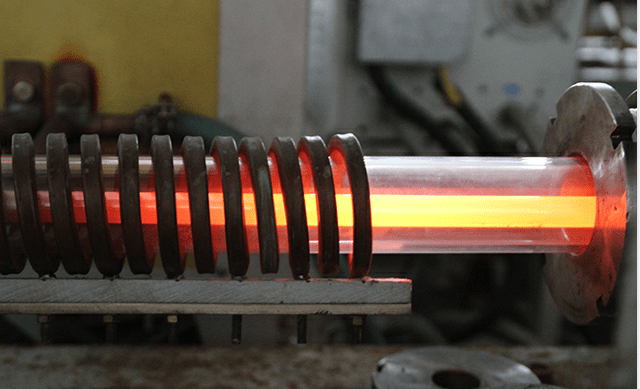

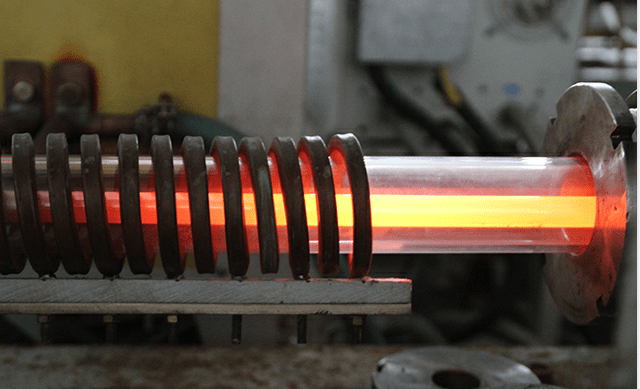

Fɛnɲɛnɛma furakɛli ye furakɛli kɛcogo ɲuman ye min bɛ se ka kɛ ni autenitic inox ye. Pipe weldalen kɔfɛ furaji furakɛli bɛ se ka sɔgɔsɔgɔninjɛ kunbɛncogo ɲuman sɔrɔ, ka fanga dɔgɔya ani ka plasitiki ɲuman sɔrɔ. O cogo dɔrɔn de la, a bɛ se ka izini pibilikiw ka ɲininiw dafa i n’a fɔ kondensalɛri pipew ani kemikɛli pipew.

Ka kɛɲɛ ni standard requirements of inox pipes for condensers ye, austenitic inox steel welded pipes ka funteni furakɛli funteni ka kan ka se 1050 ~ 1150 °C ma. O waati kelen na, a ɲininen bɛ fana pibiliki weldalenw kɔnɔna ni u kɔkanna yɔrɔw la funteni furakɛli kɔfɛ, olu ka fin ani u ka nɔgɔn, oksidan kulɛri tɛ u la. O la, a wajibiyalen don ka gɛlɛya sɔrɔ pibiliki weldalenw sumaya ni u nɛnɛ waati la. Walasa ka funteni caman ɲɔgɔnna sɛgɛsɛgɛli kɛ (foro farikolo la), nɛgɛ pipe ka kan ka kɛ lakanani yɔrɔ ɲuman na, wa laadala ji fagacogo tɛ se ka kɛ walasa ka funteni hakɛ caman pipe bali ka oksizɛni tiɲɛ ani ka pipe sanfɛla kɛ oksidan ye. A ka c’a la, autenitic inox nɛgɛ furakɛli funteni ye 1050 ~ 1150 °C ye. Ni o funteni ma se, austenitic inox kɔnɔna jɔcogo tɛ sabati, wa karɔbiw bɛna ja, o bɛ na ni nɛgɛ pipe sanfɛla ye min tɛ se kulɛri jɛlen ma, wa pipe sanfɛla bɛna kɛ i n’a fɔ nɛrɛ.

2. Gazi lakanani nɔ .

Pipe min bɛ kɛ ni nɛgɛ ye min tɛ sɔgɔ, o funteni furakɛli bɛ funteni furakɛli foro dɔ ta min tɛ oksidan sɔrɔ, gazi min bɛ a tanga, o bɛ se ka yɔrɔ jɛlen sɔrɔ ni oksidan tɛ, o bɛ kɛ sababu ye ka laadala sɔgɔli kɛcogo ban. Gazi minnu bɛ se ka baara kɛ ni u ye, olu ye idɔrɔzi saniyalenba ye, amoniyɔmu tiɲɛnen ani gazi wɛrɛw minnu bɛ u tanga. Ikomi chromium bɛ sɔrɔ pipe inox kɔnɔ, a tɛ se ka funteni furakɛli kɛ gazi la min bɛ kɛ ka a tanga (i n’a fɔ gazi hydrocarbure, a ɲɔgɔnnaw), wa a ka fisa ka a kɛ yɔrɔ la min tɛ fɛn ye. Nka, walasa ka funteni furakɛli kɛ ni pibilikiw ye minnu bɛ siri ni nɛgɛ ye, yɔrɔ min tɛ fɛn ye, o tɛ se ka kɛ, wa gazi inɛri (i n’a fɔ argon) bɛ se ka kɛ. Hali ni gazi inert (gazi) kɛli i n’a fɔ gazi lakanani min bɛ kɛ ka autenitic stainless steel welded pipes sumaya, o jogo bɛ a la ko a tɛ se ka kɛ kemikaliya walew la, a ka baarakɛcogo nɔgɔman, a tɛ lakana ani a bɛ se ka da a kan, nka a tɛ ni jogo ye min bɛ se ka kɛ sababu ye ka funteni furakɛli nɔ ɲuman sɔrɔ min ka ɲi kosɛbɛ. Warijɛ gris. Ka fara o kan, gazi inɛri musaka ka bon wa a man ɲi ka sɔrɔ ka bɔ a la. Ka kɛɲɛ ni ɲininiw ye minnu kɛra funteni furakɛli taabolo kan ani sɛgɛsɛgɛli ni sɛgɛsɛgɛli segin-seginw kan, minnu bɛ kɛ ni nɛgɛ ye min bɛ kɛ ni nɛgɛ ye, funteni furakɛli kɔfɛ, fɛɛrɛ min bɛ kɛ ka gazi inɛri baara fɔlɔ kɛ walasa ka fiɲɛ saniya funteni furakɛli foro kɔnɔ, o kɔfɛ, gazi inɛri nɔnabila, o y’a jira ko funteni furakɛli jɛlen kɛra. Jogoɲumanya wajibiyalenw. Hangao Tech (Seko masinw) . Heat Preservation Bright Annealing Heat Treating Machine ye ɛntɛrinɛti suguya minɛn ye, min dilannen don kɛrɛnkɛrɛnnenya la ni nɛgɛ ye min bɛ kɛ ni nɛgɛ ye.

3. Nɛnɛma funteni nɔ .

Ni aw ye pipe welded inox sumaya ka se 1050 ~ 1150 °C ma, pipe weldalen ka kan ka nɛnɛ joona. ka kan ka jigin ka se funteni ma min tɛ oksidan sɔrɔ. O la, nɛnɛ hakɛ nafa ka bon kosɛbɛ, wa funteni hakɛ ka kan ka kɔlɔsi kosɛbɛ.

(Inline oncement annealing foro ka ɲɛsin laser welding tube mill line ma)

4. welda pipe surface nɔfɛta .

Pipe min bɛ kɛ ni nɛgɛ ye, o sanfɛla cogoya ka sɔrɔ ka don foro kɔnɔ, o bɛ nɔba bila funteni furakɛli la min bɛ kɛ ni funteni ye. Ni pipe weldalen in sanfɛla nɔgɔlen don ni ji ye, ni tulu ye ani nɔgɔ wɛrɛw ka don foro kɔnɔ, oksizɛni jɛman kulɛri jɛman dɔ bɛna bɔ pipe weldalen sanfɛ funteni furakɛli kɔfɛ. O la, sani ka don funteni furakɛli foro la, pipe min bɛ sɔgɔ ni nɛgɛ ye, o sanfɛla ka kan ka saniya kosɛbɛ, wa pipe weldalen sanfɛla man kan ka to ka ji sɔrɔ. Ni a mago bɛ a la, a bɛ se ka ja jalen na fɔlɔ, ka sɔrɔ ka a don foro kɔnɔ.

5. Funteni furakɛli foro sigili nɔ .

Funteni furakɛli foro ka kan ka datugu ani ka bɔ kɛnɛma fiɲɛ na. Kɛrɛnkɛrɛnnenya la, pipe weldalen bɛ don foro farikolo la yɔrɔ min na ani pipe weldalen bɛ bɔ foro farikolo la yɔrɔ min na, o yɔrɔw la, sigilanw doncogo ka nɔgɔn kɛrɛnkɛrɛnnenya la, o la, a ka kan ka lajɛ tuma caman na, ka bila a nɔ na waati kɔnɔ. Walasa ka micro-leakage bali, gazi min bɛ a tanga foro kɔnɔ, o ka kan ka degun ɲuman dɔ mara. Ni gazi idɔrɔjilama don, a ka c’a la, a ka kan ka bonya ka tɛmɛ fiɲɛ tansiyɔn basigilen kan.

6. Fɛn wɛrɛw bɛ se ka kɛ funteni furakɛli la .

Baara kɛtuma na, a ka kan ka a jira ko welding bɛ to sen na ani ko a bɛ sabati. Ni dingɛw walima sɔgɔlilanw bɛ pipe weldalen kan, funteni furakɛli foro baara ka kan ka jɔ, n’o tɛ welda pipe bɛ se ka fiyɛ foro kɔnɔ. Ka fara o kan, welding effect (sɔgɔli nɔ) man ɲi, wa fiɲɛ walima ji min bɛ fiyɛ ka bɔ welding hole la, o bɛna lakana fiɲɛ tiɲɛ foro kɔnɔ ani ka nɔ bila funteni furakɛli nɔ jɛlen na.