Stainless steel welded pipe-te on-line bright heat treatment neih chhan: pakhat chu cold working process-a stainless steel strip chu tubular shape-a rolling leh welding process chhunga residual stress lo chhuak chu tihbo a ni a Austenite-a solid solution-a stainless steel welded pipe-te solid-a an thawh theihna tur leh chuta tang chuan rang taka a lum theih nan austenite chu cooling process laiin precipitation emaw phase transformation emaw a nih loh nan a tih theih nan thil pawimawh tak a ni.

On-line bright heat treatment tichhe thei thilte

1. Heat treatment temperature-in nghawng a neih dan .

Solution enkawlna hi austenitic stainless steel tan chuan softening treatment tha ber a ni. Welded pipe after solution treatment hian corrosion resistance tha ber, chakna hniam zawk leh plasticity tha zawk a hmu thei a ni. Chutiang chauh chuan industrial pipe-a condenser pipe leh chemical pipe-te mamawh a phuhruk thei ang.

Condenser atana stainless steel pipe-te standard requirement ang chuan austenitic stainless steel welded pipe-te heat treatment temperature chu 1050 ~ 1150 °C thleng tur a ni. Chutih rual chuan, heat treatment hnua welded pipe-te chhung leh pawn lam chu a var leh a hrual vek a ngai a, oxidation color a awm lo bawk. Chuvangin, welded pipe te chu a lum leh a lum laiin khauh taka tih a ngai a ni. Temperature inthlak danglamna (furnace body-a) control tur chuan steel pipe chu venhimna boruak tha takah a awm tur a ni a, chu tui quenching dan phung pangngai chu high temperature steel pipe oxygen a chhiat loh nan leh pipe chunglam a oxidize loh nan hman theih a ni lo. A tlangpuiin austenitic stainless steel solution temperature chu 1050 ~ 1150 °C a ni. He temperature hi a thlen loh chuan austenitic stainless steel chhunga structure chu a nghet lo va, carbides chu a lo chhuak ang a, chu chuan steel pipe chunglam chu rawng hring hring a thleng lo ang a, pipe chunglam chu a dum a lang ang.

2. Shielding Gas-in nghawng a neih dan .

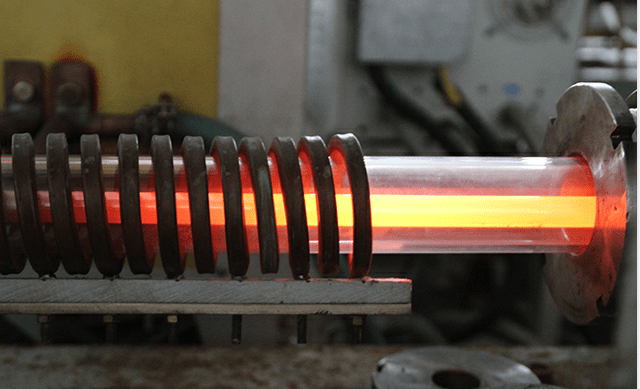

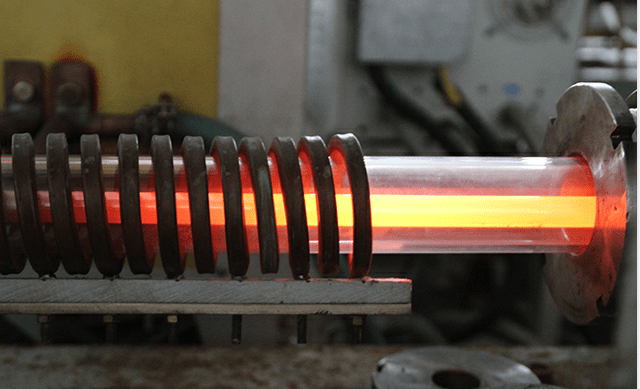

Stainless steel welded pipe-a heat treatment hian oxidation-free continuous heat treatment furnace chu protective gas hmangin a hmang a, chu chuan oxidation tel lovin surface eng tak a hmu thei a, chu chuan traditional pickling process chu a ti bo thei a ni. Protective gas hman theih tur chu high-purity hydrogen, decomposed ammonia leh protective gas dang te an ni. Stainless steel welded pipe hian chromium a pai avangin, a tlangpuiin protective gas (hydrocarbon decomposition gas, etc. ang chi) bright heat treatment tih theih a ni lo va, vacuum environment-ah pawh tih a tha ber. Mahse, in-line stainless steel welded pipe-a heat treatment atan chuan vacuum environment hman theih a ni lo va, inert gas (argon ang chi) hman theih a ni bawk. Austenitic stainless steel welded pipe-te heat treatment atana inert gas hman hian chemical reaction, simple operation, safe leh reliable-a tel lohna characteristics a nei a, mahse reducing property a nei lo a, chuvangin heat treatment effect chuan ideal bright heat treatment quality mamawh a tlin thei lo. Silver grey a ni. Chubakah, inert gas man a sang a, large-scale production atan pawh a tha lo hle. Heat treatment process chungchanga zirchianna leh bright heat treatment hnua stainless steel welded pipe quality thlirletna leh test nawn leh a nih dan chuan, heat treatment furnace-a boruak tihthianghlim nan inert gas hman hmasak a, chuta tang chuan inert gas chu hydrogen hmanga thlak a ni tih a chiang ta a ni. Quality mamawh a ni. hangao tech (Seko Machinery) tih a ni a. Heat Preservation Bright Annealing Heat Treating Machine hi online type hmanrua a ni a, stainless steel welded pipe siamna tur atana siam bik a ni.

3. Cooling temperature in nghawng a neih dan .

Stainless steel welded pipe chu 1050 ~ 1150 °C-a tihlum hnuah, welded pipe chu rang taka tihlum tur a ni. oxidize lo temperature-ah tihhniam tur a ni. Chuvangin, cooling temperature hi a pawimawh hle a, temperature range pawh khauh taka control tur a ni.

(Online-a laser welding tube mill line-a hman tur annealing furnace bright)

4. Welded pipe chunglam a nghawng dan .

Furnace chhunga a luh hmaa stainless steel welded pipe chunglam dinhmun hian bright heat treatment-ah nghawng nasa tak a nei a ni. Welded pipe chunglam chu furnace chhunga tui, grease leh bawlhhlawh dangte nen a bawlhhlawh a nih chuan, light green oxide color a rawn lang ang a, welded pipe chung lamah chuan bright heat treatment hnuah a rawn lang ang. Chuvangin, heat treatment furnace-a i luh hmain stainless steel welded pipe chunglam chu a fai hle tur a ni a, welded pipe chunglam chu tui awm phalsak loh tur a ni. A tul chuan dryer-ah a vawt hmasa thei a, chutah chuan furnace-ah dah theih a ni.

5. Heat treatment furnace sealing hian nghawng a neih dan .

Heat treatment furnace chu khar tur a ni a, pawn lam boruak atanga lakchhuah tur a ni. A bik takin welded pipe chu furnace body-a a luhna hmun leh welded pipe furnace body atanga a chhuahna hmun, heng hmuna sealing ring hi a bik takin a inbel awlsam avangin enfiah fo tur a ni a, a hun takah thlak tur a ni. Micro-leakage ven nan chuan furnace chhunga protective gas chuan positive pressure engemaw chen a vawng reng tur a ni. Hydrogen venna gas a nih chuan a tlangpuiin standard atmospheric pressure aia lian zawk a ngai a ni.

6. Bright heat treatment-a thil dangin nghawng a neih dan .

Hnathawh chhung hian welding chu a kal zel a, a nghet reng a ngai a ni. Welded pipe-a khur emaw, seam emaw a awm chuan heat treatment furnace hnathawh chu tihtawp a ngai a, chutiang a nih loh chuan welded pipe chu furnace-ah a puak thei a ni. Chu bakah, welding effect a tha lo a, welding hole atanga boruak emaw tuihnah emaw chuan furnace chhunga boruak venna boruak chu a tichhia ang a, bright heat treatment effect a nghawng bawk ang.