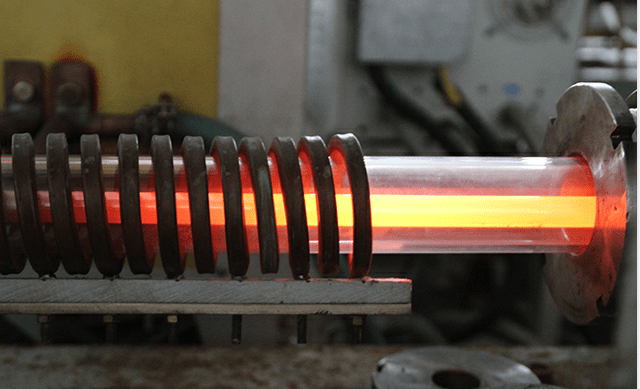

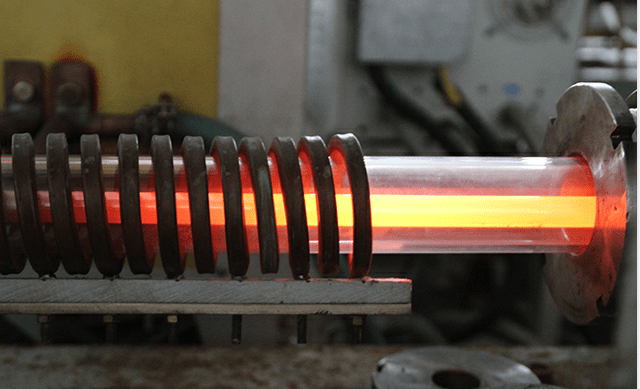

Injongo ye-on-Line yoNyango lobushushu lwe-pied yentsimbi engenasitayile: enye kukuphelisa uxinzelelo olushiyekileyo oluveliswayo ngexesha lenkqubo yentsimbi engenasitayile kwi-tublar ye-tublar kwi-tublall ye-tublar kwi-tublall ye-tublar kwi-tublall ye-tubing ye-tubing kwi-tublar Yinkqubo ebalulekileyo yokuqinisekisa ukwenziwa kwemibhobho yentsimbi engenasitali kwisisombululo esiqinileyo se-austedite kwaye ngokukhawuleza kuphole phantsi ukuthintela i-austerite ukusuka kwi-austerication kwinkqubo yokupholisa.

Izinto ezichaphazela i-intanethi yonyango olukhawulezileyo

1. Impembelelo yeqondo lobushushu lobushushu

Unyango lwesisombululo selona nkqubo lisebenzayo lonyango lwensimbi ye-austititic yenzuzo. Umbhobho we-welld emva konyango lwesisombululo unokufumana ukumelana nokunganyangeki kweyona ndawo, amandla aphantsi kunye neplastiki engcono. Kuphela yile ndlela inokuthi ifezekise iimfuno zomsebenzi wamashishini anjengemibhobho yomgaqo-nkqubo kunye nemibhobho yemichiza.

Ngokweemfuno ezisemgangathweni zemibhobho yentsimbi engenasitali yokuzibophelela, amaqondo obushushu onyango lobushushu kwe-austenaitic pipes yensimbi yentsimbi yentsimbi kufuneka ifikelele kwi-1050 ~ 1150 ℃. Kwangelo xesha, kuye kwafuneka ukuba umphezulu wangaphakathi nowangaphandle kwimibhobho ye-weldied emva konyango lobushushu amhlophe kwaye agudileyo, ngaphandle kombala we-oxidation. Ke ngoko, kuya kufuneka ukuba ingqinelwe ngexesha lokufudumeza nokupholisa imibhobho yeWelday. Ukulawula uluhlu lwamaqondo obushushu (kumzimba wesithando somlilo), umbhobho wentsimbi kufuneka ube kwimeko efanelekileyo yokukhusela, kwaye indlela yokuhamba kwamanzi ayinakusetyenziselwa ukuthintela ioksisi yentsimbi ukusuka kwi-oxygen kwaye ichaphazele umphezulu wombhobho. Ngokwesiqhelo, iqondo lobushushu lesisombululo se-austicoitic ye-Austicoitic Stainess i-1050 ~ 1150 ℃. Ukuba eli qondo lingafikeleli, isakhiwo sangaphakathi sentsimbi engenasiseko esingenakuphikiswa, kwaye i-carbides iya kulunga, ikhokelela kumqolo wentsimbi engafikeleli umbala oqaqambileyo, kwaye umphezulu womgangatho uya kubonakala mnyama.

2. Impembelelo yokuKhusela igesi

Unyango lobushushu lwe-pipe yentsimbi engenasitayile, yamkela i-oxidation ye-Oxidation Iigesi ezikhuselayo ezinokusetyenziswa zicocekile-icocekile i-hydrogen ye-hydrogen, i-ammonia eyonyule kunye nezinye iigesi ezikhuselayo. Ukusukela kumbhobho we-pilling wentsimbi equlethe i-chromium, akunakwenzeka ukwenza unyango olukhawulezileyo kwigesi yokukhusela eqhelekileyo (njengegesi yeHydrocarbon. Nangona kunjalo, ngenxa yonyango lobushushu lwe-intanethi yentsimbi yentsimbi, indawo yokuhlala ayinakusetyenziswa, kwaye irhasi ye-Intert (efana ne-ARGON) inokusetyenziswa. Nangona ukusetyenziswa kwerhasi ye-intert njengegesi yokukhusela i-gesi yokuthambisa kwe-austititic yentsimbi ineempawu zokungathathi nxaxheba kwi-special, ukuze ikhuseleke, kodwa ayinakukwazi ukuhlangabezana neemfuno ezisemgangathweni ezikhanyayo zobushushu. Isilivere grey. Ngaphaya koko, iindleko zerhasi ye-inert iphezulu kwaye ayifanelekanga kwimveliso yamangamgangatho enkulu. Ngokutsho kophando ngenkqubo yobushushu yonyango kunye nohlalutyo kunye novavanyo oluphindaphindiweyo kumgangatho we-pied yentsimbi engenasiko, kwaye emva koko isebenzise irhasi yerhasi yokucoca i-Hydrogen, kwaye ibonakalise ukuba unyango oluqaqambileyo lufezekisiwe. Iimfuno ezisemgangathweni. I-Hingao Tech (Matshini weSeko) Ukugcina ubushushu bokugcina umatshini wokunyanga ubushushu obuqaqambileyo bokunyanga sisixhobo sohlobo lwe-intanethi, senzelwe ngokukodwa kwimigca ye-pielid yentsimbi engenasitayile.

I-3. Impembelelo yokupholisa ubushushu

Emva kokufudumeza umbhobho wefliel ongenantambo ukuya kwi-1050 ~ 1150 ℃, umbhobho we-weldar wenziwe ngokukhawuleza uphononongwe ngokukhawuleza. kufuneka ihliselwe kubushushu obungayiphathiyo. Ke ngoko, ubushushu bokupholisa bubaluleke kakhulu, kwaye uluhlu lwamaqondo obushushu kufuneka lulawulwe ngokungqongqo.

(I-intanethi eqaqambileyo

I-4. Impembelelo yomgangatho we-welding pump

Imeko yomphezulu wombhobho we-boed ongenantambo ngaphambi kokuba ungene kwiziko linempembelelo enkulu kunyango oluqaqambileyo. Ukuba umphezulu wombhobho we-welding ungcoliswe ngumswakama, igrisi kunye nobunye ubumdaka esikhundleni, umbala we-oxide oqinileyo we-oxide oqinileyo uya kuvela kumphezulu wombhobho we-welding emva konyango olukhawulezileyo. Ke ngoko, ngaphambi kokungena kwiziko lonyango lobushushu, umphezulu wombhobho we-Welding ongenantambo kufuneka ucoceke kakhulu, kwaye umphezulu wombhobho we-Weldied akufuneki avunyelwe ukuba abe ngumswakama. Ukuba kukho imfuneko, ingenwe yomiswa kwindawo yokuqala, emva koko ifakwe kwiziko.

I-5. Impembelelo yeThando lobushushu lokunyanga

Iziko lonyango lomlilo kufuneka livaliwe kwaye libekwahlula kumoya ongaphandle. Ngakumbi indawo apho umbhobho we-weldie ungena khona emzimbeni we-weldace kunye nendawo apho umbhobho we-weldace uphuma umzimba we-weldace, umsesane wokutywina kwezi ndawo kuya kulula kwaye itshintshe rhoqo kwaye itshintshwa rhoqo emva kwexesha. Ukwenzela ukuthintela ukuvuza okuncinci okuvuza, igesi yokukhusela kwiziko kufuneka ilondoloze uxinzelelo oluthile. Ukuba yirhasi yokukhusela i-hydrogen, iyafuneka ukuba inkulu kunexinzelelo lomgangatho oqhelekileyo.

6. Impembelelo yezinye izinto zonyango oluqaqambileyo

Ngexesha lenkqubo yokusebenza, kuyimfuneko ukuqinisekisa ukuba i-welding iyaqhubeka kwaye izinzile. Xa kukho imingxunya okanye ithungo kumbhobho we-weldided, umsebenzi weziko lonyango lomlilo kufuneka lumiswe, kungenjalo umbhobho we-weldard unokuqunjelwa kwiziko. Ukongeza, isiphumo se-welding asilunganga, kwaye umoya okanye umswakama ojijelwe kumngxunya we-welding uya kutshabalalisa imeko yokukhusela kwiziko kwaye uchaphazele isiphumo sonyango oluqaqambileyo lobushushu.