Taɖodzinu si le dzoxɔxɔ si me dzoxɔxɔ le si me dzoxɔxɔ le si le ga si mexɔ dzo o ƒe pɔmpiwo ŋu le Internet dzi la: ɖekae nye be woaɖe nuteɖeamedzi susɔe siwo dona le dɔwɔwɔ ƒe ɖoɖo si me wowɔa dɔ le vuvɔŋɔli me la ɖa le gakpo si mexɔ dzo o ƒe fli la me ɖe nɔnɔme si nye tubular me kple le welding ƒe ɖoɖoa me; Enye mɔnu vevi aɖe be woakpɔ egbɔ be gakpo si mexɔ dzo o ƒe pɔmpiwo ƒe dɔwɔwɔ va zu solution sesẽ ɖe austenite me eye emegbe woafa kaba be austenite nagadza alo phase ƒe tɔtrɔ le fafa ƒe ɖoɖoa me o.

Nusiwo kpɔa ŋusẽ ɖe dzoxɔxɔ ƒe dɔwɔwɔ le Internet dzi dzi .

1. Dzoxɔxɔ ƒe dɔwɔwɔ ƒe dzoxɔxɔ ƒe ŋusẽkpɔɖeamedzi .

Egbɔkpɔnu ƒe atikewɔwɔ nye fafa ƒe atikewɔwɔ si wɔa dɔ wu na austenitic gakpo si mexɔ dzo o. The welded pipe after solution treatment ate ŋu akpɔ corrosion resistance nyuitɔ kekeake, ŋusẽ si bɔbɔ ɖe anyi wu kple plasticity nyuitɔ. Mɔ sia dzi koe wòate ŋu ato aɖo dɔwɔƒewo ƒe pɔmpiwo abe condenser pɔmpiwo kple atikewo ƒe pɔmpiwo ene ƒe nudidiwo gbɔ.

Le dzidzenu siwo woɖo ɖi na gakpo siwo mexɔ dzo o ƒe pɔmpiwo na condensers nu la, ele be dzoxɔxɔ si wotsɔ wɔa austenitic stainless steel welded pipes la naɖo 1050 ~ 1150 °C. Le ɣeyiɣi ma ke me la, ehiã hã be pɔmpi siwo wotsɔ ga wɔe ƒe ememe kple gota gome kple egodo le dzoxɔxɔ ƒe dɔwɔwɔ vɔ megbe nanye ɣie eye wole gbadzaa, amadede si me oxidation mele o. Eyata wobia tso esi be wòasesẽ le dzoxɔxɔ kple fafa le pɔmpi siwo wotsɔ ga wɔe la me. Be woakpɔ dzoxɔxɔ ƒe tɔtrɔ ƒe didime dzi (le dzodoƒea ƒe ŋutilã me) la, ele be gakpo ƒe pɔmpia nanɔ ametakpɔnu nyui aɖe me, eye womate ŋu azã tsi ƒe tsitretsitsimɔnu si wozãna tsã la atsɔ axe mɔ na gakpo ƒe pɔmpi si me dzoxɔxɔ le la be wòagagblẽ oxygen eye wòana pɔmpia ƒe gowo nazu oxidation o. Zi geɖe la, austenitic gakpo si mexɔ dzo o ƒe tsi si wotsɔna tsia tsii ƒe dzoxɔxɔ nyea 1050 ~ 1150 °C. Ne womeɖo dzoxɔxɔ sia gbɔ o la, austenitic gakpo si mexɔ dzo o ƒe wɔwɔme ememetɔ me li ke o, eye carbides aɖiɖi, si wɔnɛ be gakpoa ƒe akpa si le tsia dzi meɖoa amadede si klẽna o, eye pɔmpia ƒe gowo adze abe ɖe wòle yibɔ ene.

2. Gas si kpɔa ame ta ƒe ŋusẽkpɔɖeamedzi .

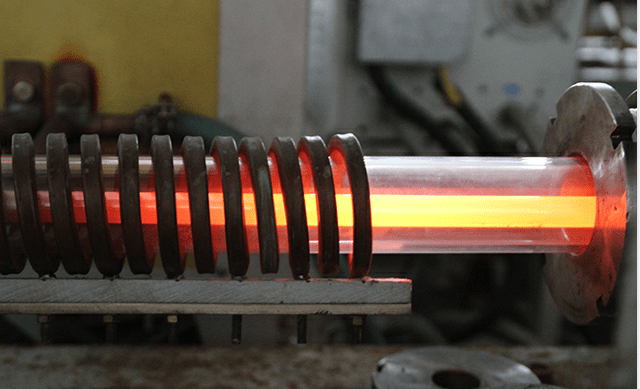

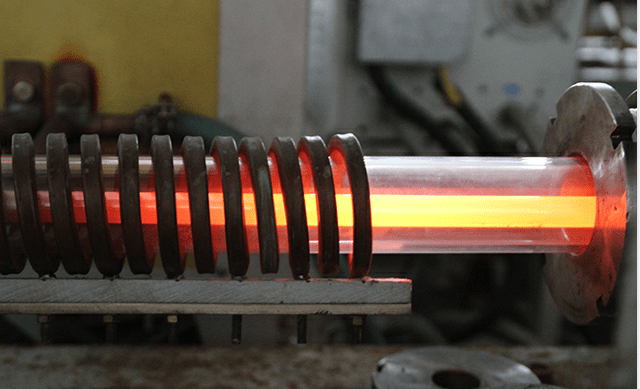

Dzoxɔxɔ ƒe dɔwɔwɔ na gakpo si mexɔ dzo o si wotsɔ ga wɔe la xɔa dzoxɔxɔ si me dzoxɔxɔ mele o si me dzoxɔxɔ mele o si me dzoxɔxɔ mele o si me ya si kpɔa ame ta le, si ate ŋu akpɔ anyigba si klẽna evɔ oxidation manɔmee, to esia me la, eɖea pickling ƒe ɖoɖo si wowɔna tsã la ɖa. Ya siwo kpɔa ame ta siwo woate ŋu azãe nye haidrodzin si le dzadzɛ ŋutɔ, ammonia si gblẽ kple ya bubu siwo kpɔa ame ta. Esi wònye be chromium le gakpo si wotsɔ gakpo si mexɔ dzo o si wotsɔ ga wɔe me ta la, manya wɔ be woawɔ dzoxɔxɔ si me kɔ nyuie le gas si kpɔa ame ta si wozãna ɖaa (abe gas si gblẽa nu le ame ŋu le hydrocarbon ene, kple bubuawo) me o, eye anyo wu be woawɔe le teƒe si ya me mekɔna o. Gake le dzoxɔxɔ ƒe dɔwɔwɔ na gakpo siwo mexɔ dzo o siwo wotsɔ ga wɔe ƒe pɔmpiwo gome la, womate ŋu azã teƒe si wotsɔa ya ƒoa nui o, eye woate ŋu azã ya si mewɔa dɔ o (abe argon ene). Togbɔ be gas si mewɔa dɔ o zazã abe gas si kpɔa ame ta hena dzoxɔxɔ ƒe dɔwɔwɔ na austenitic gakpo si mexɔ dzo o ƒe pɔmpiwo ƒe nɔnɔmewo le esi be womekpɔ gome le atikewo ƒe dɔwɔwɔ me o, dɔwɔwɔ bɔbɔe, dedienɔnɔ kple kakaɖedzi le eŋu, gake nɔnɔme siwo ɖea edzi mele eŋu o, ale be dzoxɔxɔ ƒe dɔwɔwɔ ƒe ŋusẽkpɔɖeamedzi mate ŋu aɖo dzoxɔxɔ ƒe atikewɔwɔ ƒe nyonyome si sɔ nyuie si le keklẽm la gbɔ o. Klosalo ƒe amadede nye aŋutiɖiɖi. Gakpe ɖe eŋu la, gas si mewɔa dɔ o ƒe asi sɔ gbɔ eye mesɔ na ewɔwɔ le agbɔsɔsɔ gã me o. Le numekuku si wowɔ tso dzoxɔxɔ ƒe dɔwɔwɔ ŋu kple numekuku kple dodokpɔ siwo wowɔna enuenu le gakpo si mexɔ dzo o ƒe pɔmpi ƒe nyonyome ŋu le dzoxɔxɔ ƒe dɔwɔwɔ si me kɔ vɔ megbe la, mɔnu si wozãna gbã tsɔ zãa ya si mewɔa dɔ o tsɔ kɔa ya si le dzoxɔxɔnutsitike ƒe dzodoƒea me, eye emegbe wotsɔa haidrodzin ɖoa ya si mewɔa dɔ o la teƒe la, ɖo kpe edzi be wowɔ dzoxɔxɔ si me kɔ la. Nudidiwo ƒe nyonyome ƒe nudidiwo. Hangao Tech (Seko Mɔ̃wo) Heat Preservation Bright Annealing Heat Treating Machine nye dɔwɔnu si wozãna le Internet dzi, si wowɔ etɔxɛe na gakpo si mexɔ dzo o si wotsɔ welded pipe production lines.

3. Ŋusẽkpɔɖeamedzi si le dzoxɔxɔ si fa miamiamia me .

Ne wodo dzo ɖe gakpo si mexɔ dzo o si wotsɔ welded pipe la ŋu va ɖo 1050 ~ 1150 °C vɔ la, ele be woafa pɔmpi si wotsɔ ga wɔe la kaba. ele be woaɖee ɖe anyi va ɖo dzoxɔxɔ si mewɔa oxidation o dzi. Eyata fafa ƒe dzoxɔxɔ le vevie ŋutɔ, eye ele be woakpɔ dzoxɔxɔ ƒe didime dzi pɛpɛpɛ.

(Inline keklẽ annealing dzodoƒe na laser welding tube mill fli)

4. Ŋusẽkpɔɖeamedzi si le welded pipe surface .

Nɔnɔme si me gakpo si mexɔ dzo o si wotsɔ ga wɔe la ƒe anyime hafi gena ɖe dzodoƒea kpɔa ŋusẽ gã aɖe ɖe dzoxɔxɔ ƒe dɔwɔwɔ si klẽna dzi. Ne tsi, ami kple ɖiƒoƒo bubuwo ƒo ɖi pɔmpi si wotsɔ ga wɔe la ƒe anyime la, oxide ƒe amadede dama si me kɔ la adze le pɔmpi si wotsɔ ga wɔe la ƒe anyime le dzoxɔxɔ si me kɔ vɔ megbe. Eyata hafi woage ɖe dzoxɔxɔdzidzenu ƒe dzodoƒea la, ele be pɔmpi si wotsɔ gakpo si mexɔ dzo o si wotsɔ ga wɔe la ƒe anyime nanɔ dzadzɛ ŋutɔ, eye mele be woaɖe mɔ na pɔmpi si wotsɔ ga wɔe la ƒe anyime be tsi nanɔ eme o. Ne ehiã la, woate ŋu atsɔe aƒu gbe ɖe nufamɔ̃a me gbã, eye emegbe woatsɔe ade dzodoƒea.

5. Ŋusẽkpɔɖeamedzi si le dzoxɔxɔ ƒe dɔwɔwɔ ƒe dzodoƒe ƒe nutrenu ŋu .

Ele be woatu dzoxɔxɔdzidzenu ƒe dzodoƒea eye woaɖe wo ɖe vovo tso ya si le gota la gbɔ. Vevietɔ teƒe si welded pɔmpia gena ɖe dzodoƒea ƒe ŋutilã kple teƒe si welded pɔmpia doa go le dzodoƒea ƒe ŋutilã me la, nutrenu ƒe asigɛ si le teƒe siawo la dodo le bɔbɔe ŋutɔ, eyata ele be woalé ŋku ɖe eŋu enuenu eye woaɖɔlii le ɣeyiɣi nyuitɔ dzi. Be woaxe mɔ ɖe micro-leakage nu la, ele be gas si kpɔa ame ta le dzodoƒea nalé nyaƒoɖeamenu nyui aɖe me ɖe asi. Ne enye gas si kpɔa haidrodzin ta la, zi geɖe la, wobia tso esi be wòalolo wu yame ƒe nyaƒoɖeamenu si wozãna ɖaa.

6. Nu bubuwo ƒe ŋusẽkpɔɖeamedzi ɖe dzoxɔxɔ si me kɔ nyuie dzi .

Le dɔwɔwɔ ƒe ɖoɖoa me la, ehiã be woakpɔ egbɔ be welding la yi edzi eye wòli ke. Ne do alo nusiwo wotsɔ ƒo ɖe pɔmpi si wotsɔ ga wɔe dzi la, ele be woatɔ dzo dzodoƒea ƒe dɔwɔwɔ, ne menye nenema o la, woate ŋu aƒo pɔmpi si wotsɔ ga wɔe la le dzodoƒea. Tsɔ kpe ɖe eŋu la, alesi wowɔa nu ɖe nu ŋu la menyo o, eye ya alo tsi si wotsɔ ƒo ɖe do si me wowɔa nu le la agblẽ nu le ametakpɔnu si le dzodoƒea ŋu eye wòakpɔ ŋusẽ ɖe dzoxɔxɔ ƒe dɔwɔwɔ ƒe ŋusẽkpɔɖeamedzi si le keklẽm la dzi.