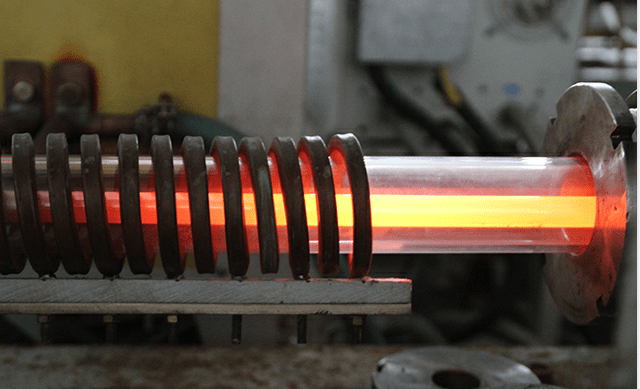

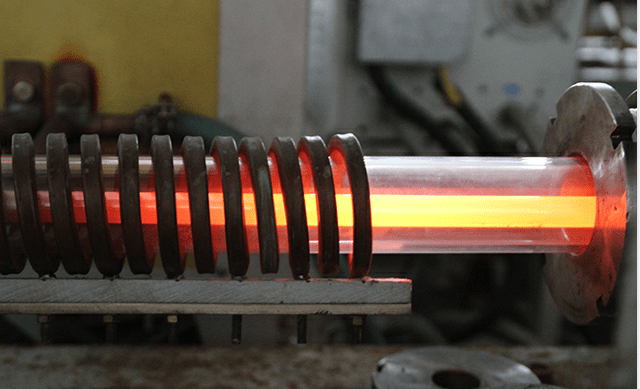

Inhloso yokwelashwa okukhanyayo okukhanyayo kwamapayipi wensimbi engenasici Kuyinqubo ebalulekile ukuqinisekisa ukusebenza kwamapayipi angenamikhawulo ensimbi eqinile kwikhambi eliqinile kwi-Autenite bese kusheshe kuphole phansi ukuvikela i-Austonite kusuka ekuguqulweni kwezulu noma ngenqubo yokupholisa.

Izici ezithinta ukwelashwa okukhanyayo okukhanyayo

1. Ithonya lokushisa lokushisa lokushisa

Ukwelashwa Isixazululo kuyinqubo ephumelela kakhulu yokwelashwa ethambile yensimbi ye-auntenitic engagqwali. Ipayipi elinenkani ngemuva kokuphathwa kwesixazululo lingathola ukumelana okungcono kakhulu kokugqwala, amandla aphansi kanye ne-plastiki engcono. Kungale ndlela kuphela lapho kuphela kungahlangabezana nezidingo zamapayipi ezimboni anjengamapayipi e-condenser namapayipi amakhemikhali.

Ngokusho kwezidingo ezijwayelekile zamapayipi ensimbi engagqwali, ukushisa kokwelashwa kokushisa kwamapayipi e-auntenitic wensimbi engenasici kufanele kufinyelele ku-1050 ~ 1150 ℃. Ngasikhathi sinye, kuyadingeka futhi ukuthi izindawo ezingaphakathi nangaphandle zamapayipi anama-welded ngemuva kokwelashwa okushisa zimhlophe futhi zibushelelezi, ngaphandle kombala we-oxidation. Ngakho-ke, kuyadingeka ukuba ngokuqinile ngesikhathi sokushisa nokupholisa amapayipi anezinwele. Ukulawula uhla lokushisa lokushisa (emzimbeni wesithando), ipayipi lensimbi kufanele libe sesimweni esihle sokuvikela, futhi indalo yendabuko yokucima ukoma ayikwazi ukusetshenziselwa ukuvikela ipayipi lensimbi eliphakeme kusuka ku-oksijini. Imvamisa, izinga lokushisa lokwelashwa kwensimbi yensimbi e-autenitic elingenacala lingu-1050 ~ 1150 ℃. Uma leli lokushisa lingafinyelelwanga, ukwakheka kwangaphakathi kwensimbi ye-auntenitic engazinzi kungazinzile, kanti ama-carbides azocima, okuholela ebusweni bepayipi lensimbi kungafinyeleli emnyama.

2. Ithonya legesi evikelekile

Ukwelashwa okushisa kwepayipi elingenacala elingenasici kumukela i-oxidation-free reatreat yokwelashwa ngomlilo ovikelayo ngegesi evikelayo, engathola indawo ekhanyayo ngaphandle kwe-oxidation, ngaleyo ndlela kuqede inqubo yokukhulisa yendabuko. Amagesi avikelayo angasetshenziswa yi-hydrogen ehlanzeke kakhulu, ebolile i-ammonia namanye amagesi wokuvikela. Njengoba ipayipi le-welded elingenasici liqukethe i-chromium, akunakwenzeka ukwenza ukwelashwa okushisa okukhanyayo ephepheni elijwayelekile lokuvikela (njengegesi yokubola kwe-hydrocarbon, njll.), Futhi kungcono ukuwenza endaweni ye-vacuum. Kodwa-ke, ngokwelashwa kokushisa kwamapayipi wensimbi engagqwayini angenazimpawu, indawo ye-vacuum ayikwazi ukusetshenziswa, kanye negesi ye-inert (njenge-argon) ingasetshenziswa. Yize ukusetshenziswa kwegesi i-inert njengokwelashwa okuvikelekile kwamapayipi e-auntenitic wensimbi engenasici anezici zokungaziphathi kahle, kepha akwenzeki ukwehlisa izakhiwo, ukuze kuncishiswe izici, ukuze umphumela wokwelashwa kokushisa awukwazi ukufeza izidingo ezisezingeni eliphakeme zokushisa zokushisa. Isiliva mpunga. Ngaphezu kwalokho, izindleko zegesi i-inert ziphezulu futhi azilungele ukukhiqizwa okukhulu. Ngokusho kocwaningo ngenqubo yokwelashwa kokushisa kanye nokuhlolwa okuphindaphindiwe kwikhwalithi yepayipi elingenamikhawulo yensimbi ngemuva kokwelashwa kwensimbi engenasici, bese kufaka phakathi i-inert gesi ku-hydrogen, bese ukufaka esikhundleni sokwelashwa okushisa okukhanyayo. Izidingo zekhwalithi. Hangao tech (seko mishini) Ukulondolozwa kokushisa okukhanyayo kokushisa okushisa okushisayo kuyinto yohlobo lwe-inthanethi, lwenzelwe ngokukhethekile imigqa yokukhiqiza yepayipi yensimbi engenasici.

3. Ithonya lokushisa lokupholisa

Ngemuva kokushisa ipayipi le-welded yensimbi engenasici libe ngu-1050 ~ 1150 ℃, ipayipi elinenkani kufanele liphonswe ngokushesha. kufanele kwehliswe kumazinga okushisa angasebenzi. Ngakho-ke, izinga lokushisa elipholile libaluleke kakhulu, futhi uhla lokushisa kufanele lulawulwe ngokuqinile.

(I-Online Enveling Traeling Furec for Laser Welding Tube Mill Line)

I-4

Isimo sobuso bepayipi elingenamikhawulo lensimbi ngaphambi kokungena esithandweni sinethonya elikhulu ekwelashweni kokushisa okukhanyayo. Uma ingaphezulu lepayipi elinenkani lingcoliswe umswakama, amafutha kanye nokunye ukungcola esithandweni somlilo, kuzovela umbala we-oxide okhanyayo ebusweni bepayipi elishisiwe ngemuva kokwelashwa okushisa okukhanyayo. Ngakho-ke, ngaphambi kokungena esithandweni sokwelashwa okushisa, ingaphezulu lepayipi elingenamikhawulo lensimbi elingenasici kufanele lihlanzeke kakhulu, futhi ingaphezulu lepayipi elinenkani akufanele livunyelwe ukuba nomswakama. Uma kunesidingo, kungamiswa esomile kuqala, bese kufakwa esithandweni somlilo.

I-5. Ithonya Lokushisa Lokwelashwa Ithoni

Isithando somlilo sokushisa kufanele sivalwe futhi sihlukaniswe nomoya ongaphandle. Ikakhulu indawo lapho ipayipi olushayelwe khona ingena khona emzimbeni wesithando nendawo lapho ipayipi eshayelwe khona iphuma khona ipayipi lomlilo, indandatho yokubopha uphawu kulezi zindawo kulula kakhulu ukugqoka, ngakho-ke kufanele ihlolwe kaningi ngesikhathi. Ukuze uvikele ukuvuza okuncane, igesi evikelayo esithandweni somlilo kufanele ilondoloze ingcindezi ethile enhle. Uma kungugesi ovikela i-hydrogen, ngokuvamile kudingeka ukuba mkhulu kunengcindezi esezingeni elijwayelekile.

I-6. Ithonya lezinye izinto ekwelashweni kokushisa okukhanyayo

Ngesikhathi sokusebenza, kuyadingeka ukuqinisekisa ukuthi i-welding iyaqhubeka futhi iyazinza. Lapho kunezimbobo noma imithungo epayipini elinenkani, umsebenzi wesithando somlilo sokushisa kufanele umiswe, uma kungenjalo ipayipi elinenkani lingashaywa esithandweni somlilo. Ngaphezu kwalokho, umphumela we-welding awumuhle, futhi umoya noma umswakama ofafazwe emgodini we-welding uzobhubhisa isimo sokuvikela esithandweni somlilo futhi uthinte umphumela wokushisa ukushisa okukhanyayo.