The purpose of on-line bright heat treatment of stainless steel welded pipes: one is to eliminate the residual stress generated during the cold working process of rolling the stainless steel strip into a tubular shape and during the welding process; It is an important process to ensure the performance of stainless steel welded pipes to solid solution into austenite and then quickly cool down to prevent austenite from precipitation or phase transformation during the cooling process.

Factors Affecting On-Line Bright Heat Treatment

1. Influence of heat treatment temperature

Solution treatment is the most effective softening treatment process for austenitic stainless steel. The welded pipe after solution treatment can obtain the best corrosion resistance, lower strength and better plasticity. Only in this way can it meet the requirements of industrial pipes such as condenser pipes and chemical pipes.

According to the standard requirements of stainless steel pipes for condensers, the heat treatment temperature of austenitic stainless steel welded pipes should reach 1050 ~ 1150 ℃. At the same time, it is also required that the inner and outer surfaces of the welded pipes after heat treatment are white and smooth, without oxidation color. Therefore, it is required to be strict during heating and cooling of the welded pipes. To control the temperature change range (in the furnace body), the steel pipe should be in a good protective atmosphere, and the traditional water quenching method cannot be used to prevent the high temperature steel pipe from decomposing oxygen and oxidizing the surface of the pipe. Usually, the solution treatment temperature of austenitic stainless steel is 1050 ~ 1150 ℃. If this temperature is not reached, the internal structure of the austenitic stainless steel is unstable, and carbides will precipitate, resulting in the surface of the steel pipe not reaching a bright color, and the surface of the pipe will appear black.

2. Influence of shielding gas

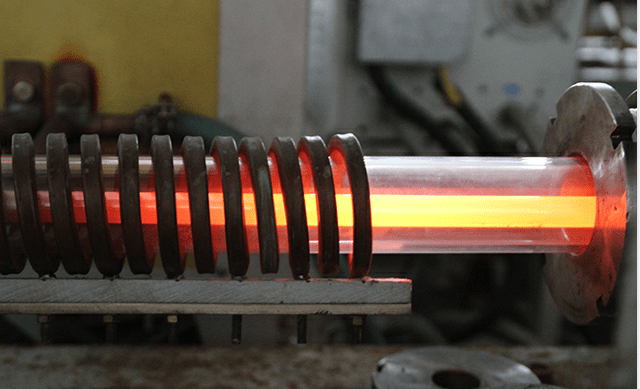

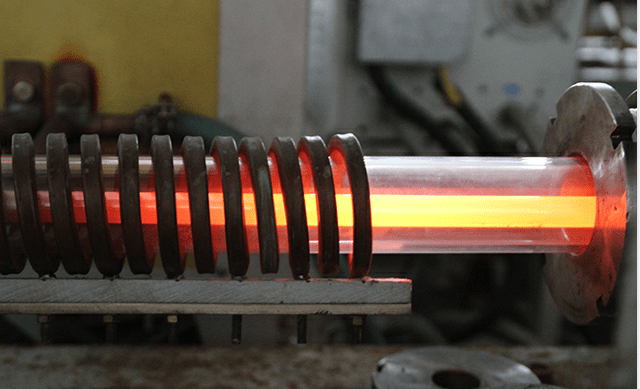

The heat treatment of stainless steel welded pipe adopts an oxidation-free continuous heat treatment furnace with protective gas, which can obtain a bright surface without oxidation, thereby eliminating the traditional pickling process. The protective gases that can be used are high-purity hydrogen, decomposed ammonia and other protective gases. Since the stainless steel welded pipe contains chromium, it is impossible to perform bright heat treatment in the usual protective gas (such as hydrocarbon decomposition gas, etc.), and it is best to perform it in a vacuum environment. However, for the heat treatment of in-line stainless steel welded pipes, a vacuum environment cannot be used, and an inert gas (such as argon) can be used. Although the use of inert gas as the protective gas for heat treatment of austenitic stainless steel welded pipes has the characteristics of not participating in chemical reactions, simple operation, safe and reliable, but it does not have reducing properties, so that the heat treatment effect cannot meet the ideal bright heat treatment quality requirements. Silver grey. Furthermore, the cost of inert gas is high and it is not suitable for large-scale production. According to the research on the heat treatment process and the analysis and repeated tests on the quality of the stainless steel welded pipe after bright heat treatment, the method of first using inert gas to purify the air in the heat treatment furnace, and then replacing the inert gas with hydrogen, has proved that bright heat treatment has been achieved. Quality requirements. Hangao Tech (SEKO Machinery) heat preservation bright annealing heat treating machine is an online type equipment, specially designed for stainless steel welded pipe production lines.

3. Influence of cooling temperature

After heating the stainless steel welded pipe to 1050 ~ 1150 ℃, the welded pipe should be quickly cooled down. should be lowered to a temperature that does not oxidize. Therefore, the cooling temperature is very important, and the temperature range should be strictly controlled.

(Online Bright Annealing Furnace for Laser Welding Tube Mill Line)

4. Influence of welded pipe surface

The state of the surface of the stainless steel welded pipe before entering the furnace has a great influence on the bright heat treatment. If the surface of the welded pipe is contaminated with moisture, grease and other dirt into the furnace, a light green oxide color will appear on the surface of the welded pipe after bright heat treatment. Therefore, before entering the heat treatment furnace, the surface of the stainless steel welded pipe should be very clean, and the surface of the welded pipe should not be allowed to have moisture. If necessary, it can be dried in the dryer first, and then put into the furnace.

5. Influence of Heat Treatment Furnace Sealing

The heat treatment furnace should be closed and isolated from the outside air. Especially the place where the welded pipe enters the furnace body and the place where the welded pipe exits the furnace body, the sealing ring in these places is particularly easy to wear, so it should be checked frequently and replaced in time. In order to prevent micro-leakage, the protective gas in the furnace must maintain a certain positive pressure. If it is hydrogen protective gas, it is generally required to be greater than the standard atmospheric pressure.

6. Influence of other factors on bright heat treatment

During the working process, it is necessary to ensure that the welding is continuous and stable. When there are holes or seams on the welded pipe, the work of the heat treatment furnace must be stopped, otherwise the welded pipe may be blown in the furnace. In addition, the welding effect is not good, and the air or moisture sprayed from the welding hole will destroy the protective atmosphere in the furnace and affect the bright heat treatment effect.