Laser welding nye welding mɔnu si wɔa dɔ nyuie eye wòdea pɛpɛpɛ si zãa laser-ya si ŋu ŋusẽ geɖe le si ŋu ŋusẽ geɖe le abe dzoxɔxɔtsoƒe ene. Egbea la, wozãa laser welding geɖe le dɔwɔƒe vovovowo, abe: elektrɔnik akpawo, ʋu wɔwɔ, yamenutome kple dɔwɔƒe bubuwo ƒe dɔwɔƒewo. Gake le laser welding ƒe ɖoɖoa me la, nu gbegblẽ aɖewo alo nusiwo gblẽ la adze godoo. Ne wose mɔ̃ siawo gɔme bliboe eye wosrɔ̃ alesi woaƒo asa na woe la, ɖe asixɔxɔ si le laser welding ŋu ate ŋu awɔ dɔ nyuie wu. Egbe, Hangao Tech (Seko mɔ̃wo) ƒuƒoƒo tsɔ wò vɛ be nàkpɔ kuxi vevi aɖewo ƒe wɔwɔfia occouring ne laser welding. Míaƒe ƒuƒoƒoa si ƒe 20 kple edzivɔ ƒe nuteƒekpɔkpɔ le automatic industrial pipe rolling kple wɔwɔ mɔ̃ me. ne hiahiã aɖe li alo ɖikeke aɖe le . Industrial laser welding tube mill line duct mɔ̃ , nyuie be nàte ɖe mía ŋu.

10 common laser weld ƒe gbagbãƒewo, woƒe nusiwo gbɔ wòtso kple egbɔkpɔnuwoe nye esiawo:

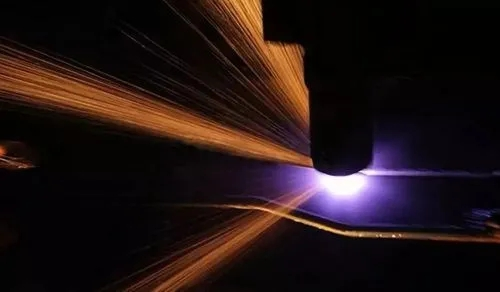

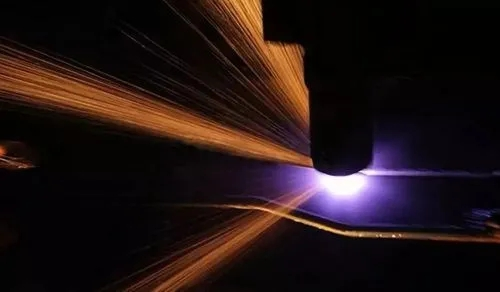

1. Weld Spatter .

Spatter si Laser Welding wɔna la kpɔa ŋusẽ ɖe weld seam ƒe anyigba ƒe nyonyome dzi vevie, si ate ŋu aƒo ɖi eye wòagblẽ nu le lens la ŋu. Dɔwɔwɔ le goawo katã me enye: Ne wowu laser welding la nu vɔ la, ga ƒe akpa geɖe dzena le nusi wotsɔ wɔe alo nusi wotsɔ wɔa dɔe ƒe anyime, eye woléa nu ɖe nusi wotsɔ wɔe alo nusi wotsɔ wɔa dɔe ƒe akpa si le edzi la dzi.

Nusiwo gbɔ splashing tsona:

Womekɔa nusi ŋu wotrɔ asi le alo nusi wotsɔ wɔa dɔa ƒe anyime ŋu o, ami ƒe ɖiɖi alo ɖiƒoƒonuwo le eme, alo ate ŋu atso nusi wotsɔ wɔe la ŋutɔ ƒe tɔtrɔ gbɔ.

Ŋuɖoɖo:

A. Lé ŋku ɖe dzadzɛnyenyenuwo alo dɔwɔnuwo ŋu hafi nàtsɔ laser awɔ nu.

B. Splash do ƒome kple ŋusẽ ƒe kpekpeme tẽ. Ne èɖe welding ŋusẽ dzi kpɔtɔ nyuie la, ate ŋu aɖe spatter dzi akpɔtɔ.

2. gbagbãƒe .

Gbeɖiɖi siwo dona tsoa laser-welding si yia edzi me la nyea dzoxɔxɔ ƒe gbagbãƒewo koŋ, abe kristalo ƒe gbagbãƒewo kple tsi ƒe gbagbãƒewo ene.

Susu siwo tae gbagbãƒewo le:

Vevietɔ le esi wòɖiɖi fũ hafi weld la mesẽ keŋkeŋ o ta.

Ŋuɖoɖo:

Dzidzenuwo abe ka si me wodea dzoe kple dzoxɔxɔ si wotsɔ doa dzoe do ŋgɔ ene ate ŋu aɖe gbagbãƒewo dzi akpɔtɔ alo aɖe wo ɖa.

3. Stoma .

Pores siwo le weld seam ƒe anyime nye nusiwo le bɔbɔe vie le laser welding me.

Nusiwo hea porosity vɛ:

A. Laser welding ƒe ta si wotsɔ ƒo ƒu la goglo eye wòle gbadzaa, eye fafa ƒe duƒuƒu le kabakaba. Ɣeyiɣi aɖeke mele gas si dona le tsi si me wodea tsii me la si be wòayɔ fũ o, si wɔnɛ be ʋuʋudediwo dzɔna bɔbɔe.

B. Womekɔa weld seam la ƒe anyime o, alo zinc vapor si le galvanized sheet la me ya ƒua du.

Ŋuɖoɖo:

Klɔ dɔwɔnua ƒe akpa si le edzi kple alesi wotsɔa ga ƒoae la ƒe anyime hafi nàtsɔe aƒoe be zinc ƒe dzoxɔxɔ nanyo ɖe edzi ne wodo dzoe. Tsɔ kpe ɖe eŋu la, mɔ si dzi woato aƒo ya la akpɔ ŋusẽ ɖe yadoƒewo ƒe dzidzime hã dzi.

4. Wozi edzi .

Undercut fia: welding seam la me ƒo ƒu nyuie kple base metal o, groove li, goglome la lolo wu 0.5mm, eye didime bliboa lolo wu 10% le weld ƒe didime me, alo wòlolo wu didime si dzi lɔlɔ̃ ɖe edzi ƒe dzidzenua bia.

Susu si le ete:

A. Welding ƒe duƒuƒu le du dzi akpa, eye womagagbugbɔ ga si le weld la me la ama le do sue la ƒe megbe o, si ana woatsoe ɖe ete le weld la ƒe akpa eveawo.

B. Ne ƒunukpeƒea ƒe ƒuƒoƒo ƒe ƒuƒoƒo lolo akpa la, woɖea ga si wotsɔ ƒo ƒu ɖe ƒunukpeƒea me la dzi kpɔtɔna, eye etsotso hã dzi ɖena kpɔtɔna.

C. Le laser welding ƒe nuwuwu la, ne ŋusẽ ƒe ɖiɖi ƒe ɣeyiɣia le du dzi akpa la, do sue la ƒe mumu le bɔbɔe, si hã ana woatso nutoa me le nutoa me.

Ŋuɖoɖo:

A. Kpɔ dɔwɔwɔ ƒe ŋusẽ kple duƒuƒu ƒe sɔsɔ le laser welding mɔ̃a dzi be nàƒo asa na undercutting.

B. Woate ŋu awɔ weld si wokpɔ le ŋkuléleɖenuŋua me la ƒe anyime, akɔ eŋu ahadzrae ɖo be wòaɖo nudidi siwo le dzidzenu si dzi woxɔa ame ɖo la gbɔ.

5. Weld ƒe ƒuƒoƒo .

Edze ƒã be weld seam la yɔ fũ akpa, eye weld seam la kɔ akpa ne wole nu yɔm.

Nusiwo hea weld ƒe ƒuƒoƒo vɛ:

Nuɖuɖu ƒe duƒuƒu kabakaba akpa alo welding ƒe duƒuƒu le blewu akpa le welding me.

Ŋuɖoɖo:

Dzi welding ƒe duƒuƒu ɖe edzi alo nàɖe ga si wotsɔna naa nuɖuɖui ƒe duƒuƒu dzi akpɔtɔ, alo nàɖe laser ƒe ŋusẽ dzi akpɔtɔ.

6. Welding deviation .

Ga si wotsɔ wɔa gae la masẽ ɖe ƒunukpeƒea ƒe titina o.

Susu siwo tae nɔnɔme sia le:

Teƒe si womede pɛpɛpɛ o le welding me, alo ɣeyiɣi si me wotsɔa ga ƒoa nui si me mekɔ o kple welding wire alignment.

Ŋuɖoɖo:

Trɔ asi le welding ƒe nɔnɔme ŋu, alo trɔ asi le ɣeyiɣi si woatsɔ adzrae ɖo kple afisi welding wire le, kpakple akaɖia ƒe nɔƒe, welding wire kple welding seam.

7. Weld seam blanuiléle .

Weld nyrɔ̃e fia nudzɔdzɔ si nye be weld ga la ƒe anyigba dzi nu te ɖe edzi.

Nusiwo gbɔ weld nyrɔ̃ tso:

Le brazing me la, solder joint titina menyo o. Kekeliƒea ƒe titina te ɖe agba si le ete la ŋu eye wòte ɖa tso weld la ƒe titina, si wɔnɛ be ga si wotsɔ ƒoe la ƒe akpa aɖe ƒoa.

Ŋuɖoɖo:

Trɔ asi le kekeli ƒe filament ƒe sɔsɔ ŋu.

8. Weld ƒe wɔwɔme madeamedzi .

Weld ƒe wɔwɔme madeamedziwo dometɔ aɖewoe nye: weld ripples manyomanyo, weld siwo mesɔ o, tɔtrɔ si mesɔ o le weld kple base gas dome, weld dahewo, kple weld siwo mesɔ o.

Nusitae nɔnɔme sia le:

Ne wotsɔ weld seam la blae la, ka si wotsɔ ƒoa ka la meli ke o, alo kekelia meyina edzi o.

Ŋuɖoɖo:

Trɔ asi le mɔ̃a ƒe liƒo ŋu.

9. Welding .

Weld Bead fia: Ne weld ƒe mɔzɔzɔa trɔ ŋutɔ la, weld bead alo uneven forming nye nusi dzena le dzogoea dzi bɔbɔe.

Nusiwo gbɔ wòtso:

Seam track la trɔna ŋutɔ, eye nufiafiaa mesɔ o.

Ŋuɖoɖo:

Weld le parameter nyuitɔwo te, trɔ asi le dzogoe si dzi nàkpɔe le ŋu be dzogoeawo nawɔ ɖeka.

10. Anyigba ƒe slag ƒe gomekpɔkpɔ le eme .

Surface slag inclusions ƒo nu tso: le welding ƒe ɖoɖoa me la, ŋutigbalẽ ƒe slag inclusions siwo woate ŋu akpɔ tso egodo la dzena le ƒuƒoƒoawo dome koŋ.

Susu me dzodzro le anyigbadzi slag inclusion ŋu:

A. Le multi-layer multi-pass welding me la, interlayer coating la mele dzadzɛ o; alo weld ƒe ƒuƒoƒo si nɔ anyi va yi la ƒe anyime mele gbadzaa o alo weldment la ƒe anyime meɖo nudidiawo gbɔ o.

B. Welding dɔwɔwɔ ƒe mɔnu siwo mesɔ o abe low welding input energy kple welding ƒe duƒuƒu kabakaba akpa.

Ŋuɖoɖo:

A. Tia welding current kple welding ƒe duƒuƒu si sɔ. Ele be woakɔ nusiwo wotsɔ blaa nuawo dome le multi-layer multi-pass welding me.

B. Grinding Be woaɖe weld seam kple slag inclusion le anyigba dzi, dzra welding ne ehiã.