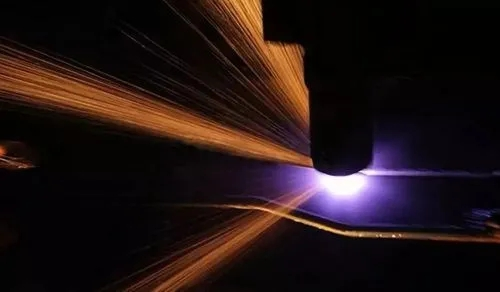

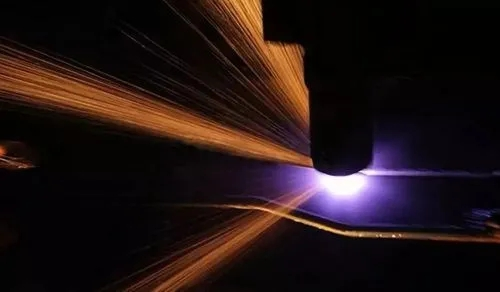

Laser welding yɛ ɔkwan a ɛyɛ adwuma yiye na ɛyɛ pɛpɛɛpɛ a wɔfa so yɛ welding a ɛde laser hann a ahoɔden kɛse wom di dwuma sɛ ɔhyew fibea. Ɛnnɛ, wɔde laser welding adi dwuma kɛse wɔ nnwuma ahorow mu, te sɛ: ɛlɛtrɔnik afã horow, kar a wɔyɛ, ahunmu ne mfiridwuma mu nneɛma afoforo a wɔyɛ. Nanso, wɔ laser welding mu no, sintɔ ahorow bi anaa nneɛma a asɛe bi bɛba a wontumi nkwati. Ɛdenam saa afiri yi a wobɛte ase yiye na woasua sɛnea wobɛkwati so nkutoo na wobetumi de laser welding bo no adi dwuma yiye. Ɛnnɛ, Hangao Tech (Seko mfiri) kuw no de wo ba sɛ wubenya ɔhaw atitiriw bi a ɛyɛ occouring bere a wɔde laser welding ayɛ no ho nsusuwii. Yɛn kuw no wɔ bɛboro mfe 20 osuahu wɔ automatic industrial pipe rolling ne forming machine mu. Sɛ ɛho hia anaasɛ adwenem naayɛ bi wɔ hɔ a . Industrial laser welding tube mill line duct afiri , yɛma wo akwaaba sɛ wobɛkɔ yɛn nkyɛn.

10 common laser weld sintɔ ahorow, nea ɛde ba ne ano aduru te sɛ nea edidi so yi:

1. Weld Spatter .

Spatter a laser welding de ba no nya weld seam no ani su so nkɛntɛnso kɛse, a ebetumi ayɛ fĩ na asɛe aniwa no. Adwumayɛ a ɛwɔ hɔ nyinaa ne sɛ: Sɛ wɔde laser welding no wie a, dade mu nneɛma nketenkete pii pue wɔ ade anaa adwuma no ani, na ɛbata ade anaa adwuma no ani.

Nea ɛde nsu a ɛpetepete ba:

Wɔnnsiesie nneɛma a wɔayɛ ho adwuma anaasɛ nea wɔde yɛ adwuma no ani, ngo a ɛyɛ fĩ anaasɛ efĩ wɔ hɔ, anaasɛ ebetumi afi nneɛma no ankasa a ɛyɛ hyew no mu aba.

Anoyie:

A. Hwɛ nneɛma a wɔde siesie hɔ anaa nneɛma a wɔde yɛ adwuma ansa na wode laser ayɛ welding.

B. Splash ne tumi a ɛyɛ den no wɔ abusuabɔ tẽẽ. Welding ahoɔden a wɔbɛtew so sɛnea ɛfata no betumi atew spatter so.

2. Mpaapaemu .

Mpaapaemu a ɛnam laser welding a ɛkɔ so yɛ so no yɛ ɔhyew mu mpaapaemu titiriw, te sɛ ahwehwɛ mu mpaapaemu ne mpaapaemu a ɛyɛ nsu.

Nneɛma a ɛma mpaapaemu ba:

Titiriw esiane sɛ shrinkage a ɛboro so ansa na weld no nyɛ den koraa nti.

Anoyie:

Nneɛma a wɔyɛ te sɛ waya a wɔde hyɛ mu ne nea wɔde di kan yɛ no hyew no betumi atew mpaapaemu so anaasɛ ayi afi hɔ.

3. Stoma .

Pores a ɛwɔ weld seam no ani no yɛ sintɔ a ɛnyɛ den koraa wɔ laser welding mu.

Nea ɛde porosity ba:

A. Laser welding a wɔabɔ no apete no mu dɔ na ɛyɛ teateaa, na ahoɔhare a ɛma onwini no yɛ ntɛmntɛm. Mframa a ɛba wɔ ɔtare a nsu ayɛ mu ma no mu no nni bere a ɛbɛboro so, na ɛyɛ mmerɛw sɛ ɛbɛma ntini a ɛwɔ mu no ayɛ kɛse.

B. Wɔnnsiesie weld seam no ani, anaasɛ zinc vapor a ɛwɔ galvanized sheet no mu no yɛ nwini.

Anoyie:

Hohoro adwuma no ani ne weld no ani ansa na welding no ayɛ yiye na ama zinc no ayɛ hyew bere a wɔayɛ no hyew no. Nea ɛka ho no, ɔkwan a wɔfa so bɔ no nso bɛka mframa mu ntokuru awo ntoatoaso no.

4. Wɔatwitwa so .

undercut kyerɛ: welding seam no nnyɛ yie a ɛka base metal no ho, ɛwɔ groove, bun no boro 0.5mm, na ne nyinaa tenten boro 10% wɔ weld no tenten mu, anaasɛ ɛboro ne tenten a wɔhwehwɛ wɔ acceptance standard no mu.

Nea enti a ɛte saa:

A. Welding ahoɔhare no yɛ ntɛmntɛm dodo, na wɔrensan nkyekyɛ dade a ɛyɛ nsu a ɛwɔ weld no mu no wɔ tokuru ketewa no akyi, na ɛyɛ underming wɔ weld no afã abien no nyinaa.

B. Sε nkwaa no ntam kwan a εbεboaboa ano no sε εsεn dodo a, dadeɛ a ayow a εwɔ nkwaa no mu no so tew, na undercutting nso taa ba.

C. Wɔ laser welding awiei no, sɛ ahoɔden a ɛkɔ fam bere no yɛ ntɛmntɛm dodo a, ɛnyɛ den sɛ wobebubu tokuru ketewa no, na ɛno nso bɛma mpɔtam hɔ ayɛ mmerɛw.

Anoyie:

A. Hwɛ tumi a wɔde yɛ adwuma ne ahoɔhare a ɛne laser welding afiri no hyia no so na amma wɔantwa.

B. Wobetumi ayɛ weld a wohu wɔ nhwehwɛmu no mu no ase, asiesie na wɔasiesie na ama atumi adi ahwehwɛde ahorow a ɛwɔ agyede gyinapɛn no mu no ho dwuma.

5. Weld a ɛboaboa ano .

Ɛda adi sɛ weld seam no yɛ ma boro so, na weld seam no korɔn dodo bere a worehyɛ no ma no.

Nea ɛde weld a ɛboaboa ano ba:

Wire feeding speed yɛ ntɛmntɛm dodo anaasɛ welding ahoɔhare yɛ brɛoo dodo wɔ welding mu.

Anoyie:

Ma welding ahoɔhare no nkɔ soro anaasɛ tew ahoɔhare a wode ma wire no so, anaasɛ tew laser ahoɔden so.

6. Welding deviation .

Weld dade no renyɛ den wɔ nkwaa no mfinimfini.

Nneɛma a ɛma tebea yi te:

gyinabea a ɛnteɛ bere a welding, anaasɛ inaccurate filling welding bere ne welding wire alignment.

Anoyie:

Siesie welding no gyinabea, anaa sesa bere a wɔde siesie welding ne baabi a welding waya no wɔ, ne sɛnea kanea no wɔ, welding waya ne welding seam no.

7. Weld seam a ɛyɛ basaa .

Weld sinking kyerɛ adeyɛ a ɛne sɛ weld dade no ani ayɛ basaa no.

Nea ɛde weld kɔ fam:

Bere a wɔreyɛ brazing no, solder joint no mfinimfini nyɛ papa. hann no mfinimfini bɛn mprɛte a ɛwɔ fam no na ɛtwe ne ho fi weld no mfinimfini, na ɛma dade a ɛwɔ ase no fã bi wosow.

Anoyie:

Siesie hann nhama a ɛne no hyia no.

8. Weld a ɛnyɛ papa .

Nea ɛka weld a ɛnyɛ papa ho ne: weld a ɛnyɛ papa, welds a ɛnyɛ pɛpɛɛpɛ, nsakrae a ɛnyɛ pɛpɛɛpɛ wɔ welds ne base metals ntam, welds a enye, ne weld a ɛnyɛ pɛpɛɛpɛ.

Nea enti a tebea yi te:

Sɛ weld seam no yɛ brazed a, wire feeding no ntumi nnyina, anyɛ saa a hann no nkɔ so.

Anoyie:

Siesie sɛnea afiri no gyina pintinn no.

9. Welding .

Weld Bead kyerɛ sɛ: Sɛ weld trajectory no sesa kɛse a, weld bead anaasɛ uneven forming no taa pue wɔ ntwea so.

Nea ɛde ba:

Seam track no sesa kɛse, na nkyerɛkyerɛ no nyɛ pɛpɛɛpɛ.

Anoyie:

Weld wɔ parameters a eye sen biara ase, siesie angle of view no na ama ntwea no ayɛ pɛpɛɛpɛ.

10. Slag a ɛwɔ soro no ka ho .

Surface slag inclusions kyerɛ: bere a welding no rekɔ so no, skin slag inclusions a wotumi hu fi akyi titiriw no pue wɔ layers ntam.

Nteaseɛ mu nhwehwɛmu a ɛfa slag a ɛwɔ soro a wɔde ka ho ho:

A. Wɔ multi-layer multi-pass welding mu no, interlayer coating no ho ntew; Anaasɛ weld a atwam no ani nyɛ mmerɛw anaasɛ weldment no ani ntumi nni ahwehwɛde ahorow no ho dwuma.

B. Welding dwumadie akwan a ɛmfata te sɛ welding ahoɔden a ɛba fam a wɔde hyɛ mu ne welding ahoɔhare a ɛyɛ ntɛm dodo.

Anoyie:

A. Paw welding current a ntease wom ne welding ahoɔhare. Ɛsɛ sɛ wɔhohoro interlayer coating no mu wɔ multi-layer multi-pass welding mu.

B. Grinding Sɛ wobɛyi weld seam a ɛwɔ slag inclusion wɔ soro no a, siesie welding sɛ ɛho hia a.