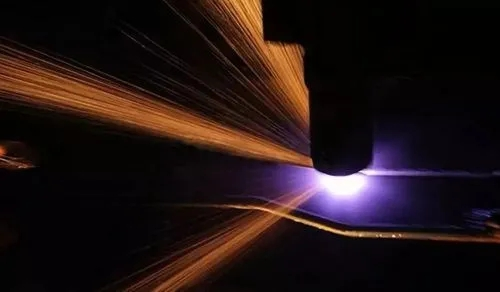

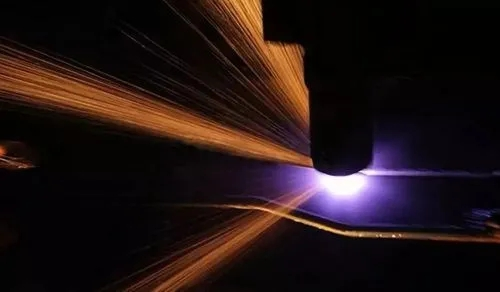

I-Laser Weling isebenza kakuhle kunye nendlela ye-weldise esebenzisa i-Laser-Anser-i-Inser-Anser ePhezulu ye-Laser ye-Beam njengoMthombo wobushushu. Namhlanje, i-Laser Welling isetyenziswe ngokubanzi kumashishini ahlukeneyo, ezinje: Inxalenye ye-elektroniki, imveliso yemoto, imveliso yemoto, i-aerospace kunye neminye imimandla yokwenziwa kwemveliso. Nangona kunjalo, kwinkqubo ye-lare yelding, ezinye iziphene okanye iimveliso ezinesiphene ziya kuvela ngokungathandabuzekiyo. Kuphela ngokuqonda ngokupheleleyo ezi zinto zimbi kwaye ufunde indlela yokuphepha kunokubaluleka kwemveliso yase-laser esetyenzisiweyo. Namhlanje, Iqela le -Hingao Tech (Matshini weSeko) kukuzisa ukuba ube nesishwankathelo sezinye iingxaki eziphambili kakhulu xa uselunxwemeni. Iqela lethu linamava angaphezu kwama-20 kumzi mveliso we-pied kunye noomatshini. Ukuba kukho nayiphi na imfuneko okanye ukuthandabuza malunga Umzi mveliso wase-Laser Welling Tube ye-dube ye-dube , wamkelekile ukunxibelelana nathi.

I-10 yesiphene se-serser ye-leld ye-Willies, oonobangela kunye nezisombululo kunye nolu hlobo lulandelayo:

I-1. I-SPATTT

I-Spatter eveliswe nguLaser Welding ichaphazela umgangatho womhlaba womphezulu womthungo we-WED, onokubangcolisa kwaye wonakalise ilensi. Umsebenzi ngokubanzi:

Unobangela wokubhula:

Izinto ezisetyenzisiweyo okanye umphezulu womsebenzi awucocwanga, kukho iigatha zeoyile okanye ingcoliseko, okanye inokubangelwa kukuzinzakala kwezinto ezibonakalayo ngokwalo.

Isisombululo:

A. Nika ingqalelo kwizixhobo zokucoca okanye izinto zomsebenzi ngaphambi kokuba i-werling welding.

B. I-splash ihambelana ngqo nengxinano yamandla. Ukunciphisa ngokufanelekileyo amandla eWeldling kungayinciphisa spatter.

2. Ukuqhekeka

Imingxunya eveliswa yi-Ilser eqhubekayo ye-ilding ikakhulu yimingxunya ye-fermal, ezinje ngobuthathaka obukristali kunye notywala.

Izizathu ze-rocks:

ikakhulu ngenxa yokuncitshiswa kakhulu ngaphambi kokuba i-sheld ayiqinanga ngokupheleleyo.

Isisombululo:

Amanyathelo anje nge-cire yokugcwalisa kunye nokuchama kunokuphucula okanye ukuphelisa imicukuvuzo.

I-3. Stoma

I-pores kumphezulu womthungo we-weld zinesiphene esilula kwi-lared yelding.

Unobangela wokubetheka:

A. Iphuli enyikima ye-leser welling inzulu kwaye imxinwa, kwaye isantya esipholileyo siyakhawuleza. Igesi eyenziwe kwiphuli ye-nyibilikisi engenasithuba sokuphuphuma kwayo, ekhokelela ngokulula ekwenzeni iipores.

B. Umphezulu womthungo we-weld akacocwa, okanye umphunga we-zinc lwephepha le-pincan.

Isisombululo:

Coca umphezulu womsebenzi kunye nomphezulu we-weld ngaphambi kokuba uwenze i-seltiling ye-zinc xa ishushu. Ngapha koko, ulwalathiso lokuvuthuza luya kuchaphazela nakwesizukulwana semingxunya yomoya.

I-4. Iphantsi

I-PROCT Ibhekisa kwi: I-Weld Seam ayidityaniswa kakuhle nentsimbi yesiseko, kukho i-Groove, ubunzulu bungaphezulu kwe-0.5mm inkulu kune-10% yobude obufunekayo, okanye ngaphezulu kobude obufunyenwe ngumgangatho wokwamkelwa.

Isizathu se-DEATUCT:

A. Isantya se-welding sikhawuleza kakhulu, kwaye intsimbi yolwelo kwi-SIDT ayiyi kuphinda ithunyelwe ngasemva komngxunya omncinci, ukwenza amacala omabini amacala we-weld.

B. Ukuba isithuba sendibano sikhulu kakhulu, isinyithi esityhidiweyo ekugcwaliseni ihlazo lincitshisiwe, kwaye ukulungisa i-oxcout ithathelwe ukwenzeka.

C. Ekupheleni kwe-laser yelding, ukuba ixesha lokuyeka kwamandla likhawuleza kakhulu, umngxunya omncinci kulula ukuwa, okuya kubangela nakubangela i-purcut yendawo.

Isisombululo:

A. Lawula amandla okulungisa kunye nokuhambelana nesantya somatshini we-laser welding ukuphepha ukungcola.

B. I-SURCT ye-weld efunyenwe ekuhlolweni inokutyhilwa, icocwe kwaye ilungiswe ukuze ifezekise iimfuno zomsebenzi wokwamkela.

I-5. Ukuqokelelwa kwe-WERL

Umthungo we-WOld ngokucacileyo ugcwalisiwe, kwaye umthungo we-wel uphakame kakhulu xa ugcwalisa.

Unobangela wokuqokelelwa kwe-Wold:

Isantya sokwenza iwire sikhawuleza kakhulu okanye isantya se-welding sicotha kakhulu ngexesha le-welding.

Isisombululo:

Yandisa isantya se-welding okanye sinciphise isantya sokutya, okanye ukunciphisa amandla ase-laser.

I-6. Ukuphambuka

Intsimbi ye-Wold ayiyi kukodwa embindini wesakhiwo esidibeneyo.

Izizathu zale meko:

Ukuma ngokungachanekanga ngexesha lokugcwala, okanye ukugcwalisa okungachanekanga kwelding kunye nolungelelwaniso locingo.

Isisombululo:

Lungisa indawo ye-welding, okanye uhlengahlengise ixesha lokulungisa i-welding kunye nesikhundla se-wire ye-welding, kunye nendawo yesibane, i-wilding wires.

I-7. I-WORD Seam Day

Ukutsala kwe-WOLD kubhekisa kwi-panomenon apho umhlaba wentsimbi ye-weld uxinezelekile.

Izizathu zokwenza i-shld:

Ngexesha lokubhabha, iziko leThuthi imbi lihlwempu lihlwempu. Iziko lendawo yokukhanya likufuphi neplate esezantsi kwaye liphambuka ukusuka embindini womthungo we-weld, obangela intsimbi yentsimbi yesiseko ukuze inyibilike.

Isisombululo:

Lungisa i-filament yokukhanya.

I-8. Ukwakhiwa kwe-weld

Ukuqulunqwa kwe-Weld Weld Weld, i-Wild yeDelds, i-Wels engalinganiyo, i-irection engalinganiyo phakathi kwe-wels kunye nezinyithisi, kunye ne-ils ehluphekayo.

Isizathu sale meko:

Xa i-Wold Seam ibhule, ukondlwa kocingo akunakuzinza, okanye ukukhanya akuyo.

Isisombululo:

Lungisa uzinzo lwesixhobo.

I-9. I-welding

I-Weld Bead ibhekisa: Xa i-Weld Trajectory Gratchry kakhulu, i-Welld Bead okanye i-foance engalinganiyo ifakwe kwikona.

Unobangela:

Umkhondo we-Seam Seam utshintsha kakhulu, kwaye imfundiso ayilingani.

Isisombululo:

I-WOLD Phantsi kweeparamitha ezilungileyo, lungisa i-engile yejoni yokujonga iikona ezihambelanayo.

I-10. Umphezulu we-slag

I-Slag ye-Slag Slag ibhekisa kwi: Ngexesha lenkqubo ye-welding, i-slag slag ifakelwe ukusuka ngaphandle kwaphela ivele phakathi kweendawo.

Isizathu sokuhlalutya kwe-Slag ye-Slag

A. Ngexesha lokudlulisela i-welti-willing ye-welsi, umnxibelelanisi akahlambulukanga; Okanye umphezulu wengqimba wangaphambili we-weld ayigudileyo okanye umphezulu wendalo awuhlangabezana neemfuno.

B. Iindlela zokusebenzela ezingalunganga zeWolding ze-Welding ezifana ne-Polling ye-Wellwork ye-Welding kunye nesantya seWolding Speed.

Isisombululo:

A. Khetha isantya esifanelekileyo selding kunye ne-welding. Iqela lomnxibelelanisi kufuneka licocwe ngexesha lokudlula kwimidlalo emininzi.

B. Ukugaya ukususa umthungo we-weld nge-slag kwi-slag kumphezulu, ukulungisa i-welding ukuba kuyimfuneko.