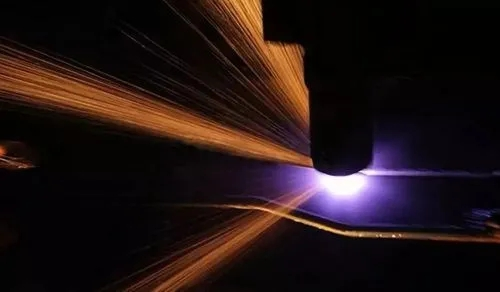

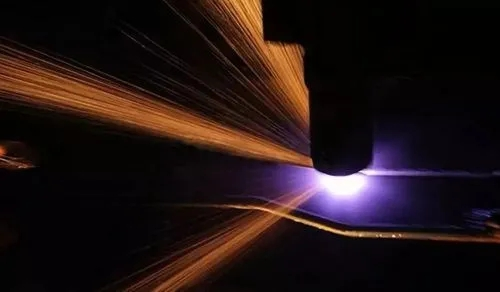

Laser welding ye welding fɛɛrɛ ye min nafa ka bon kosɛbɛ ani min bɛ kɛ ni laser-fiɲɛ ye min fanga ka bon i n’a fɔ funteni sɔrɔyɔrɔ. Bi, laser welding kɛra baarakɛminɛn ye kosɛbɛ baarakɛyɔrɔ suguya caman na, i n’a fɔ: ɛntɛrinɛti yɔrɔw, mobili dilanni, aerospace ani izini dilanyɔrɔ wɛrɛw. Nka, laser welding (laser welding) kɛcogo la, fiɲɛ dɔw walima fɛn tiɲɛnen dɔw bɛna bɔ kɛnɛ kan. Ni o jaanw faamuyalen don kosɛbɛ dɔrɔn ani ni u bɛ se ka u yɛrɛ tangacogo dege, o bɛ se ka kɛ ni laser welding nafa ye ka ɲɛ. Bi, Hangao Tech (Seko Machinery) jɛkulu bɛ na ni i ye walasa ka gɛlɛyabaw dɔw lajɛ minnu bɛ mɔgɔ minɛ ni laser welding ye. An ka jɛkulu ka san 20 ni kɔ dɔnniya bɛ sɔrɔ automatique industrie pipe rolling ani forming machine la. Ni mago bɛ yen walima ni siga bɛ yen . Industrie laser welding tube mill line duct machine , aw bɛ se ka anw sɔrɔ.

10 Laser welda tiɲɛni minnu ka teli ka kɛ, u sababuw ni u furakɛcogo bɛ nin cogo la:

1. welda ka spatter .

Laser welding bɛ fɛn min bɔ, o bɛ nɔba bila welda seam sanfɛla cogoya la, o bɛ se ka lensɛri nɔgɔ ani ka a tiɲɛ. A ka baara kɛcogo bɛɛ ye : laser welding dafalen kɔfɛ, nɛgɛ caman bɛ bɔ fɛn walima baarakɛminɛn sanfɛ, ka nɔrɔ fɛn walima baarakɛminɛn sanfɛla la.

Splashing sababuw:

Fɛn min dilannen don walima baarakɛminɛn in sanfɛla tɛ saniya, tulu nɔgɔlenw walima nɔgɔw bɛ yen, walima a bɛ se ka sɔrɔ fɛn yɛrɛ jiginni fɛ.

Fɛɛrɛ:

A. Aw bɛ aw janto saniyafɛnw walima baarakɛminɛnw na sani laser ka welding kɛ.

B. Splash bɛ tali kɛ fanga density la. Ni a bɛnnen don ka dɔ bɔ welding energie la, o bɛ se ka dɔ bɔ a la.

2. ka fara .

Fara minnu bɛ Bɔ laser welding continue (laser-sɔgɔli) la olu ye funteni-yɔrɔw ye kosɛbɛ, i n’a fɔ kristalɛ-faraw ani ji-yɔrɔw.

Kun minnu b’a jira ko kariw:

kɛrɛnkɛrɛnnenya la k'a sababu Kɛ dɔgɔyali kojugu ye ka Sɔrɔ welda ma Sɔ̀rɔ pewu.

Fɛɛrɛ:

Fɛɛrɛ minnu bɛ kɛ i n’a fɔ nɛgɛw falenni ni u sumaya, olu bɛ se ka dɔ bɔ walima ka u ban.

3. Stoma .

Pores minnu bɛ weld seam kan, olu ye fiɲɛ ye min ka nɔgɔn kosɛbɛ laser welding na.

Porosité sababuw:

A. Laser welding (laser welding) jidaga min bɛ wuli, o ka dun ani a ka dɔgɔ, wa nɛnɛ teliya bɛ teliya. Gazi min bɛ bɔ jibolisira jilama kɔnɔ, waati tɛ o la ka tɛmɛn, o bɛ na ni ɲɛgɛnɛsiraw dilanni ye nɔgɔya la.

B. welda seam sanfɛla tɛ saniya, walima zinc vapor of the galvanized sheet evaporates.

Fɛɛrɛ:

Aw bɛ baarakɛminɛn in sanfɛla ni a sɔgɔli yɔrɔ saniya sani aw ka welding kɛ walasa ka zinki wulicogo ɲɛ ni a sumana. Ka fara o kan, fiɲɛbɔyɔrɔ bɛna nɔ bila fiɲɛ dingɛw bɔli fana na.

4. Undercut .

Undercut b’a jira ko : welding seam tɛ fara ɲɔgɔn kan kosɛbɛ ni basigi nɛgɛ ye, groove bɛ yen, a juguya ka bon ni 0,5mm ye, ani a janya bɛɛ ka bon ni 10% ye welda janya la, walima ka tɛmɛ janya kan min bɛ ɲini sɔnni sariya fɛ.

Undercut Reason:

A. welding teliya bɛ teliya kojugu, wa nɛgɛ jilama min bɛ welda la, o tɛna tila kokura dingɛ fitinin kɔfɛ, ka jukɔrɔlatigɛw kɛ welda fan fila bɛɛ la.

B. Ni kolotugudaw ka ɲɔgɔn lajɛyɔrɔ ka bon kojugu, nɛgɛ wulilen min bɛ joli la, o bɛ dɔgɔya, wa a jukɔrɔla tigɛcogo fana ka teli ka kɛ.

C. Laser welding laban na, ni fanga jigin waati teliyalen don, dingɛ fitinin in binni ka nɔgɔn, o fana bɛna kɛ sababu ye ka sigida tiɲɛni kɛ.

Fɛɛrɛ:

A. Laser welding masin ka baarakɛcogo ni a ka teliya bɛnkan kɔlɔsi walasa a kana tiɲɛ.

B. welda min bɛ sɔrɔ sɛgɛsɛgɛli la, o jukɔrɔla tigɛlen bɛ se ka polisi, ka saniya ani ka dilan walasa a ka se ka sɔn sariya ka sariyaw ma.

5. welda dalajɛli .

A jɛlen don ko welda seam bɛ fa kojugu, wa welda seam ka bon kojugu ni a bɛ fa.

welda dalajɛ sababuw:

Wire balo teliya bɛ teliya kojugu walima welding teliya bɛ sumaya kojugu welding waati la.

Fɛɛrɛ:

Aw bɛ dɔ fara sɔgɔli teliya kan walima ka nɛgɛ balo teliya dɔgɔya, walima ka laser fanga dɔgɔya.

6. welding deviation .

welda nɛgɛ tɛna solidify (soliditif) joli-sira-funu cɛmancɛ la.

Kun minnu b’a jira ko nin ko in bɛ kɛ:

A jɔyɔrɔ tiɲɛni welding waati la, walima fali waati tiɲɛni waati ani welding wire alignment.

Fɛɛrɛ:

Aw bɛ welding kɛyɔrɔ ladilan, walima ka dilan waati ni welding wire jɔyɔrɔ ladilan, ka fara lanpan, welding wire ani welding seam jɔyɔrɔ kan.

7. weld seam depression .

Weld sinking (sɔgɔsɔgɔninjɛ) bɛ kuma o ko kan ko welda nɛgɛ sanfɛla bɛ degun.

Weld Sinking sababuw:

Brazing waati la, solder joint (solder joint) cɛmancɛ man ɲi. Yeelen yɔrɔ cɛmancɛ bɛ gɛrɛ duguma-plati la ka bɔ welda cɛmancɛ la, o bɛ kɛ sababu ye ka nɛgɛ basigilen yɔrɔ dɔ wuli.

Fɛɛrɛ:

Aw bɛ filament yeelenma ɲɔgɔndan ladilan.

8. welda man ɲi .

Welda jɔcogo jugu dɔw ye: welda ripples juguw, welda tɛ kelen ye, welda ni nɛgɛ basigilenw, welda juguw, ani welda tɛ kelen ye.

O ko in sababu:

Ni welda sɔgɔlen bɛ siri, nɛgɛ baloli tɛ sabati, walima yeelen tɛ to ka taa ɲɛ.

Fɛɛrɛ:

Aw bɛ minɛn in sabatili ladilan.

9. welding .

Weld bead bɛ tali kɛ: Ni weld trajectory yeli caman kɛra, weld bead walima uneven forming bɛ teli ka bɔ nkɔni na.

A sababuw:

Seam track bɛ Changé kosɛbɛ, wa kalan tɛ kelen ye.

Fɛɛrɛ:

Aw bɛ aw yɛrɛ sɔgɔ paramɛtiri ɲumanw jukɔrɔ, aw bɛ a fan dɔ ladilan walasa ka nkɔniw kɛ ɲɔgɔn fɛ.

10. Surface Slag inclusion .

Surface slag inclusions refer (Sɔrɔdasiw) bɛ tali kɛ: welding (sɔgɔli) kɛcogo la, farikolo-sɔgɔli-minɛnw minnu bɛ se ka ye ka bɔ kɛnɛma, olu bɛ ye kɛrɛnkɛrɛnnenya la layiniw ni ɲɔgɔn cɛ.

Hakilila sɛgɛsɛgɛli kan surface slag inclusion:

A. Multi-layer multi-pass welding waati la, interlayer coating tɛ saniya; walima welda layɛrɛ kɔrɔ sanfɛla tɛ nɔgɔya walima welda yɔrɔ tɛ wajibiw dafa.

B. welding operation (sɔgɔli baarakɛcogo) kɛcogo bɛnbaliw i n’a fɔ welding input energy (dadon fanga dɔgɔyali) ani welding teliya teliya kojugu.

Fɛɛrɛ:

A. Aw bɛ welding current ni welding teliya hakɛ bɛnnen sugandi. A ka kan ka saniya ni fɛn caman ye, a ka kan ka saniya ni fɛn caman ye.

B. Grinding ka welda seam bɔ ni slag inclusion ye a sanfɛ, ka welding dilan ni a mago bɛ a la.