Welding Welding shine babban aiki da kuma ainihin walda wanda ke amfani da katako mai ƙarfi-makamashi mai ƙarfi azaman tushen zafi. A yau, an yi amfani da Welding Laser a cikin masana'antu daban-daban, kamar: sassan lantarki, masana'antu na motoci, Aerospace da sauran filayen masana'antu masana'antu. Koyaya, a kan aiwatar da walsing, wasu cututtukan lahani ko kayan masarufi ba su bayyana ba. Ta hanyar fahimtar wadannan makamancin haka da koyon yadda za a nisanta su iya iya amfani da layin laser. A yau, Hangao Tech (kayan masarufi na Seko) Team kawo ku don yin taƙaitaccen bayani game da wasu manyan matsalolin da ke faruwa a lokacin da layin laser. Teamungiyarmu ta sami kwarewa sama da shekara 20 a cikin bututun masana'antu ta atomatik mirgina da injin samar da injin. Idan akwai wani buƙata ko shakku game da Masana masana'antu na masana'antu na masana'antu na masana'antu na masana'antu , barka da saduwa da mu.

10 La'ammala na Weld na Wels, abubuwan da suke haifar da su da mafita sune kamar haka:

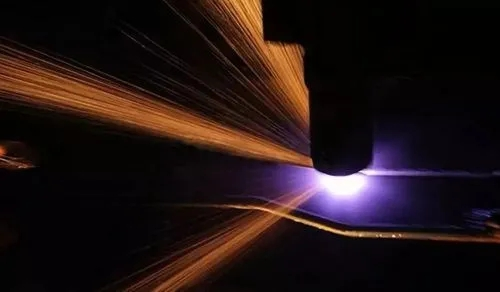

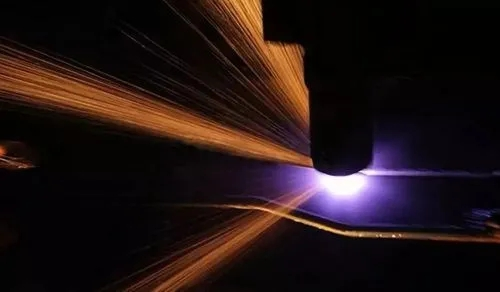

1. Weld spatter

Spatter da Laser Welding ya shafi ingancin ingancin Seam, wanda zai iya gurbata da kuma lalata ruwan tabarau. Babban aikin shine: bayan an kammala Welding Laser, barbashi na ƙarfe na ƙarfe suna bayyana akan saman kayan ko kayan aiki, da kuma bin saman kayan ko kayan aiki.

Sanadin fashewa:

Ba a tsabtace kayan da aka sarrafa ba ko kuma ba a tsabtace kayan aikin ba, akwai ƙyallen mai ko gurbata abubuwa, ko kuma ta haifar da volatilization na kayan da kansa.

Magani:

A. Kula da tsaftace kayan ko aiki kafin layin Laser.

B. Spash ne mai dangantaka da kai tsaye da yawa. Yadda ya dace yana rage ƙarfin kuzari na iya rage feater.

2. Crack

Abubuwan fashewa da aka samar da ci gaba da walwala na laser sune yawancin fasahar theral din, kamar su crystal fasa da kuma crystalction fasa.

Dalilai na fasa:

galibi saboda wuce kima kafin weld ba a tabbatar da tabbaci ba.

Magani:

Matakan kamar wanda ke cike da waya da kuma preheating zai iya raguwa ko kawar da fasa.

3. Stosa

Pores a farfajiya na Weld Seam suna da cikakkiyar lahani a cikin walding na laser.

Sanadin mamaki:

A. Gamayen layin zinare yana da zurfi da kunkuntar, kuma saurin sanyi yana da sauri. Gaskiyar gas a cikin ruwan tafkin Molten tana ba da lokacin da za ta ambaci, wanda cikin sauƙi yana haifar da samuwar pores.

B. An tsabtace saman seld Seam, ko kuma kurwar ƙwayar zinc na galvanized takardar ya bushe.

Magani:

Tsaftace farfajiya da farfajiya na Weld kafin walda don inganta volatilization na zinc lokacin zafi. Bugu da kari, shugabanci na hurarrun zai shafi tsara ramuka na iska.

4. GASKIYA

Cikakken abin da aka yi na nufin: Seaming din da aka haɗa sosai tare da ƙarfe na tushe, zurfin ya fi 10% a kan tsayin weld, ko mafi girma daga cikin daidaitaccen da aka buƙata.

Dalilin Dalili:

A. Gudun walƙwalwar waldi ya yi sauri sosai, da ƙarfe na ruwa a cikin Weld ba za a sake rubikewa a bayan karamin karamin rami ba, forcings incuts a garesu na Weld.

B. Idan Majalisar ta gaza haɗin gwiwa ya yi yawa, baƙin ƙarfe a cikin cika cika haɗin gwiwa yana raguwa, kuma an sanya shi a zahiri.

C. A ƙarshen walsing welding, idan saukarwar makamashi ya yi sauri, ƙaramin rami yana da sauƙin rushe, wanda kuma zai haifar da undercut.

Magani:

A. Gudanar da ƙarfin sarrafawa da saurin motsi na injin laser don guje wa ba da labari.

B. Cikakkiyar da aka samu a cikin binciken za'a iya goge shi, tsabtace kuma a gyara shi don yin biyan bukatun ka'idojin karban.

5. Weld tarawa

Seam Seam a fili ya cika da nasara, kuma weld dinku yana da yawa lokacin cika.

Sanadin Weld Trovelation:

Saurin ciyar da waya yana da sauri ko saurin walding ya yi jinkiri sosai yayin waldi.

Magani:

Theara saurin walding ko rage saurin ciyar da waya, ko rage ikon laser.

6. Walda karkacewa

Karfe na Weld ba zai ƙarfafa a tsakiyar tsarin haɗin gwiwa ba.

Dalilin wannan halin:

Ba daidai ba wuri yayin waldi, ko ba daidai ba ne walding lokacin da waldi da kayan aiki.

Magani:

Daidaita matsayin walda, ko daidaita lokacin waldia da matsayin waya mai walda, da matsayin fitilar, welding waya da waldi.

7. Weld kumar seam

Weld nutsewa yana nufin sabon abu cewa Weld Mace na baƙin ciki yana da baƙin ciki.

Sanadin Welel Fiting:

A lokacin da Brazing, tsakiyar rundunar hadin gwiwa matalauta ce. Cibiyar hasken haske tana kusa da ƙaramin farantin da karkace daga tsakiyar Seam na Weld, yana haifar da ɓangaren ƙarfe ya narke.

Magani:

Daidaita dace da filament filament.

8. Talauci Weld

Talauci Weld Selt ya hada da: Welds Welds, Welds mara kyau, Matsayi mara kyau tsakanin Welds da karatattun ƙarfe, welds, welds, da walds.

Dalilin wannan halin:

Lokacin da aka Brain Seam, ciyarwar waya ba shi da tabbas, ko hasken ba shi ci gaba.

Magani:

Daidaita kwanciyar hankali na na'urar.

9. Welding

Weld bead yana nufin: Lokacin da aka canza yanayin yanayin yanayi sosai, weld bead ko ba a daidaita forming yana yiwuwa ya bayyana a kusurwa.

Sanadin:

Siffar Saka Track yana canzawa sosai, kuma koyarwar ba ta daidaita ba.

Magani:

Weld a karkashin mafi kyawun sigogi, daidaita kusurwar kallo don yin sasanninta mai ma'ana.

10. SLAG SLAG hada

Surfacewar surface ya koma zuwa ga: a lokacin aiwatar da waldi, fatar fata Slag manch daga waje yakan bayyana tsakanin yadudduka.

Dalili na Binciken Surface Slag hade:

A. A yayin walwing mai yawa-Layer Multi-Passing, mai sarrafa maiter ba shi da tsabta; Ko kuma farfajiya na Weld na Weld ba shi da laushi ko farfajiya na walwala ba ya cika bukatun.

B. Rashin Ingantaccen Welding na ba da izinin sarrafa wutar lantarki ba kuma saurin saukar da sauri mai sauri.

Magani:

A. Zabi wani walwala mai ma'ana da kuma saurin walwal. Dole ne a tsabtace ta a lokacin welding da yawa-Layer Multi-Passarewa.

B. Drinding don cire Weld Seam tare da slag hada kan saman, gyara duk abin da idan ya cancanta.