I-Laser Welding isebenza kahle futhi indlela eqondile esebenzisa i-Laser enamandla yamandla aphezulu njengendawo yokushisa. Namuhla, i-laser welding isetshenziswe kabanzi emikhakheni ehlukahlukene, efana: izingxenye ze-elekthronikhi, ukukhiqiza izimoto, i-aerospace kanye namanye amasimu okukhiqiza izimboni. Kodwa-ke, kwinqubo ye-laser welding, ezinye iziphambeko noma imikhiqizo engenaphutha zizovela nakanjani. Ukuqonda ngokuphelele lezi zingqinamba nokufunda ukuthi ungazigwema kanjani inani le-laser welding lisetshenziswe kangcono. Namuhla, Ithimba le -Hanao Tech (Seko Tech) likulethela ukuba ube nokubuka konke kwezinkinga ezinkulu ezenzeka lapho i-laser welding. Iqembu lethu linolwazi olungaphezulu kweminyaka engama-20 ku-othomathikhi yepayipi lezezimboni nokwakha umshini. Uma kukhona isidingo noma ukungabaza ngakho I-Industrial Laser Welding Tube Mille Duct Machine , wamukelekile ukuxhumana nathi.

Iziphetho ezijwayelekile ze-laser zamanzi, izimbangela zabo kanye nezixazululo zinjengokulandelayo:

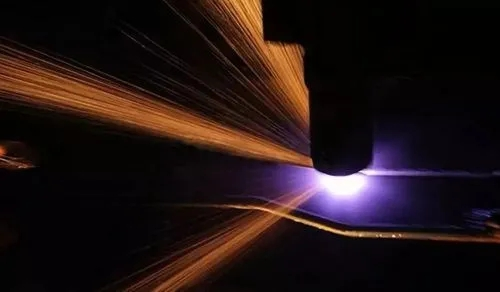

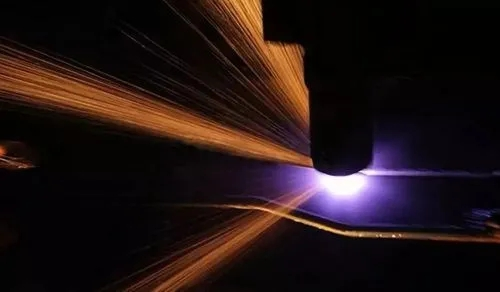

1. I-Weld Spatter

I-spate ekhiqizwa nguLaser Welding ithinta kakhulu ikhwalithi ephezulu ye-Weld Seam, engangcolisa futhi ilimaze ilensi. Ukusebenza okujwayelekile yile: Ngemuva kokuqedwa kwe-laserr welding, izinhlayiya eziningi zensimbi zivela ebusweni bezinto ezibonakalayo noma zomsebenzi wokusebenza, futhi banamathela ebusweni bezinto ezibonakalayo noma zokusebenza.

Izimbangela zokuqhuma:

Izinto ezicutshunguliwe noma ingaphezulu le-workpiece alihlanzwa, kunamabala kawoyela noma ukungcola, noma kungahle kubangelwa ukuguquguquka kwezinto ezibonakalayo uqobo.

Isixazululo:

A. Naka izinto zokuhlanza zokuhlanza noma ama-Workies ngaphambi kokufudumala kwe-laser.

B. Splash ahlobene ngokuqondile nobunzima bamandla. Ukunciphisa amandla okunciphisa i-welding kunganciphisa i-spatter.

2. Ukuqhekeka

Imifantu ekhiqizwa yi-welding eqhubekayo ye-laser iwukuqhekeka okushisayo ikakhulukazi, njengokuqhekeka kwekristalu kanye nemifantu ye-liquefaction.

Izizathu zokufakelwa:

ikakhulukazi ngenxa yokushwabana ngokweqile ngaphambi kokuthi iWeld ingaqiniswa ngokuphelele.

Isixazululo:

Izinyathelo ezinjengokugcwaliswa kocingo nokuqala ukugcwala kunganciphisa noma ukuqeda imifantu.

3. I-Stoma

Ama-pores ebusweni be-weld seam anezinkinga ezilula eLaser Welding.

Izimbangela Zokuqina Kwenzintshi:

A. I-molten pool of laser welding ijulile futhi incane, futhi ijubane lokupholisa liyashesha. Igesi ekhiqizwe echibini elicwengekileyo lingenaso isikhathi sokuchichima, okuholela kalula ekwakhekeni kwama-pores.

B. Ingaphezulu le-Weld Seam alihlanzwa, noma i-Zinc Vapor yeshidi egayiwe.

Isixazululo:

Hlanza ingaphezulu le-workpiep Ngaphezu kwalokho, ukuqondiswa okushayayo kuzothinta nesizukulwane sezimbobo zomoya.

4. Undercut

Undercut ubhekisa ku: Umthungo we-welding akahlanganiswe kahle nensimbi eyisisekelo, kukhona i-groove, ukujula kukhulu kune-0.5mm, ubude obukhulu bukhulu kune-10% yobude be-weld, noma ubukhulu obudingekayo ngokwezinga lokuvunyelwa.

Isizathu Esingaphansi:

A. Ijubane le-welding lishesha kakhulu, futhi insimbi ewuketshezi eWeld ngeke iphinde yabiwe ngemuva emgodini omncane, yakha ama-undercuts kuzo zombili izinhlangothi ze-weld.

B. Uma igebe lomhlangano lokuhlangana likhulu kakhulu, insimbi ebilisiwe ekugcwalisweni kokuhlanganiswa incishisiwe, futhi undercting athambekele futhi.

C. Ekupheleni kwe-laserser welding, uma isikhathi sokuphonsa amandla sishesha kakhulu, umgodi omncane kulula ukuwa, okuzobuye kubangele ukufunwa kwendawo.

Isixazululo:

A. Lawula amandla okucubungula kanye nokufana kwejubane lomshini we-laser welding ukugwema ukumboza.

B. Ukwehlukaniswa kweWeld okutholakele ekuhlolweni kungavinjelwa, kuhlanzwe futhi kulungiswe ukukwenza kuhlangabezane nezidingo ze-Amumerance Standation.

5. Ukuqongelela kweWeld

Umthungo we-weld ngokusobala uyagcwaliswa ngokweqile, futhi umthungo we-weld uphakeme kakhulu lapho kugcwaliswa.

Izimbangela Zokuqongelela Weseld:

Isivinini sokudla socingo sishesha kakhulu noma ijubane le-welding lihamba kancane ngesikhathi selding.

Isixazululo:

Khuphula isivinini se-welding noma ukunciphisa isivinini sokudla socingo, noma ukunciphisa amandla we-laser.

6. Ukuphambuka kwe-welding

Insimbi yeWeld ngeke ivimbele enkabeni yesakhiwo esihlanganyelwe.

Izizathu zalesi simo:

Ukuma okungalungile ngesikhathi sokufudumeza, noma ukugcwalisa okungalungile kwe-welding nesikhathi kanye nokuqondanisa kwe-welding wire.

Isixazululo:

Lungisa isikhundla se-welding, noma ulungise isikhathi sokulungisa i-welding kanye nesikhundla socingo lwe-welding, kanye nesikhundla sesibani, i-wire ye-welding kanye nomthungo we-welding.

7. Ukudana kwe-Weld Seam

Ukucwila kweWeld kubhekisele emcimbini wokuthi indawo yensimbi ye-weld yedwa icindezelekile.

Izimbangela zokucwila kweWeld:

Ngesikhathi sokubhidliza, isikhungo somthengisi ohlanganayo simpofu. Isikhungo sendawo yokukhanya siseduze nepuleti elingaphansi futhi siphambuke kusuka enkabeni yomthungo we-weld, okubangela ingxenye yensimbi eyisisekelo ukuncibilika.

Isixazululo:

Lungisa ukufana kwe-filament ekhanyayo.

8. Ukwakheka kwe-wald

Ukwakheka kwe-weld okungomuhle kufaka phakathi: Ama-weld ampofu, ama-weld angalingani, ukuguqulwa okungalingani phakathi kwama-welds kanye nezinsimbi ezisezingeni eliphansi, nama-welds ampofu.

Isizathu salesi simo:

Lapho umthungo we-weld uvuthiwe, ukondliwa kocingo akuzinzile, noma ukukhanya akuqhubeki.

Isixazululo:

Lungisa ukuqina kwensiza.

9. I-Welding

I-Weld Bead isho ukuthi: Lapho i-weld trajectory ishintsha kakhulu, ubuhlalu be-weld noma ukwakheka okungalingani kuthambekele ekubonakaleni ekhoneni.

Izimbangela:

Ithrekhi yomthungo ishintsha kakhulu, futhi imfundiso ayilingani.

Isixazululo:

I-Weld ngaphansi kwamapharamitha amahle kakhulu, lungisa i-angle yokubuka ukuze wenze amagumbi ahlangana.

10. Ukufakwa kwe-Surface Slag

Ukufakwa kwe-Surface Slag okubhekiswe ku: Ngesikhathi senqubo ye-welding, inhlanganisela yesikhumba ebonakalayo engabonakala kusuka ngaphandle ivela ikakhulukazi phakathi kwezendlalelo.

Ukuhlaziywa kwesizathu sokufakwa kwe-slag slag:

A. Ngesikhathi se-relti-ungqimba i-walding multi-pass welding, umxhumanisi wokuhlambana awuhlanzekile; Noma ingaphezulu lesendlalelo esedlule seWelld alibushelelezi noma ingaphezulu kwe-weldentiment alihlangabezani nezidingo.

B. Amasu wokusebenza okungafanele wokufaka we-welding afana namandla aphansi wokufaka we-welding kanye nesivinini se-welding esheshayo.

Isixazululo:

A. Khetha isivinini se-welding selding esinengqondo nesenqatsheni. I-interlayer coating kumele ihlanzwe ngesikhathi se-relti-pass welding ehlukahlukene.

B. Ukugaya ukuze ususe umthungo we-weld ngokufakwa kwe-slag ebusweni, ukulungisa i-welding uma kunesidingo.