Le viɖe siwo le dɔwɔwɔ nyuie ŋutɔ, nuwɔwɔ pɛpɛpɛ, emetsonu nyuiwo, kple automation ƒe ƒoƒo ɖekae bɔbɔe ta la, wozãa laser welding geɖe le dɔwɔƒe vovovowo me eye wòwɔa akpa vevi aɖe le dɔwɔƒewo wɔwɔ kple wo wɔwɔ me, siwo dometɔ aɖewoe nye asrafowo, atikewɔwɔ, yamenutomeyimɔ̃, 3C ʋu ƒe akpa aɖewo, kple mɔ̃ siwo wotsɔ ga gbadzɛwo wɔe. Sika, ŋusẽ yeye, tsileƒe ƒe xɔtunuwo kple dɔwɔƒe bubuwo.

Gake mɔnu ɖesiaɖe si woazã atsɔ awɔ dɔ le eŋu la ana nusiwo gblẽ alo nusiwo gblẽ le wo ŋu la nado ne womebi ɖe eƒe gɔmeɖosewo kple dɔwɔwɔwo me o, eye laser-welding hã mele eme o. Ne míese nɔnɔme gbegblẽ siawo gɔme nyuie eye míesrɔ̃ alesi woaƒo asa na woe la, míate ŋu azã asixɔxɔ si le laser welding ŋu nyuie wu eye míawɔ dɔ tso nusiwo ƒe dzedzeme dzeani kple woƒe nyonyome deŋgɔ ŋu. Ƒuƒoƒo si me tɔwo nye . Hangao Tech (Seko mɔ̃wo) ƒo nuteƒekpɔkpɔ siwo nɔ anyi ɣeyiɣi didi nu ƒu, eye asisiwo ƒe nyaŋuɖoɖo aɖewo tso zazã me ƒo ƒu . Laser welding stainless steel welded tube forming machine , eye wòƒo nu tso egbɔkpɔnu aɖewo ŋu kpuie na welding ƒe gbɔdzɔgbɔdzɔ siwo bɔ hena numekuku tso dɔwɔƒea ƒe dɔwɔhatiwo gbɔ!

1. gbagbãƒewo .

Gbeɖiɖi siwo dona le laser welding si yia edzi me la nyea dzoxɔxɔ ƒe gbagbãƒewo koŋ, abe kristalo ƒe gbagbãƒewo, tsi ƒe gbagbã, kple bubuawo ene.Nu vevitɔe nye be weld la wɔa shrinkage ŋusẽ gã aɖe hafi wòli ke keŋkeŋ. Dzidzenuwo abe ka si wotsɔ yɔa ka me kple dzoxɔxɔ si wotsɔna ƒoa dzoe ene ate ŋu aɖe gbagbãƒeawo dzi akpɔtɔ. alo woaɖe gbagbãƒewo ɖa.

▲Kracked welds .

2. Stomata .

Porosity nye nɔnɔme madeamedzi si wowɔna bɔbɔe le laser welding me. Laser welding ƒe ta si wotsɔ ƒo ƒu la goglo eye wòle gbadzaa, eye fafa ƒe agbɔsɔsɔme le kabakaba ŋutɔ. Gas si dona le tsi si me wode tsii me la mekpɔa ɣeyiɣi si sɔ gbɔ be wòasi o, si ate ŋu ana ʋuʋudediwo nadzɔ bɔbɔe. Gake laser welding fa miamiamia kabakaba eye zi geɖe la, ʋuʋudedi siwo dona la le sue wu fusion welding si wozãna tsã. Dɔwɔnu si wotsɔ wɔa dɔe la kɔklɔ hafi welding ate ŋu aɖe ʋuʋudedi ƒe didi dzi akpɔtɔ, eye alesi ya ƒoe ƒe mɔfiame hã akpɔ ŋusẽ ɖe ʋuʋudediwo ƒe dzɔdzɔ dzi.

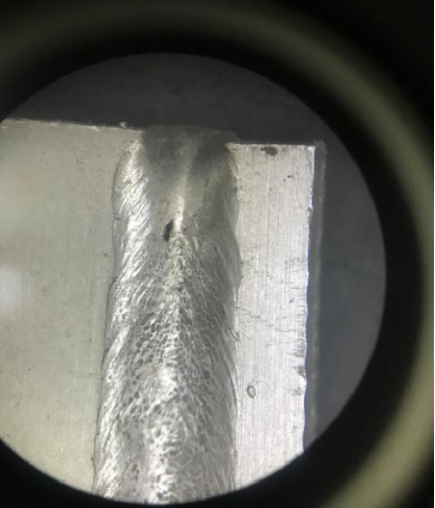

▲Weld pores (miame) .

3. Splash .

Spatter si Laser Welding wɔna la kpɔa ŋusẽ ɖe weld ƒe anyigba ƒe nyonyome dzi vevie eye wòte ŋu ƒoa ɖi eye wòagblẽ nu le lens la ŋu. Spatter do ƒome tẽ kple ŋusẽ ƒe tsɔtsɔme, eye alesi woɖea welding ŋusẽ dzi kpɔtɔna nyuie ate ŋu aɖe spatter dzi akpɔtɔ. Ne gege ɖe lãme na ame mesɔ gbɔ o la, woate ŋu aɖe welding ƒe duƒuƒu dzi akpɔtɔ.

▲Welding spatter .

4. Wozi edzi .

Ne ga si wotsɔ ƒoa gae ƒe duƒuƒu le du dzi akpa la, ga si le do sue si fia asi weld titina la ƒe megbe la makpɔ ɣeyiɣi atsɔ agbugbɔ amae o, eye wòali ke le weld la ƒe akpa eveawo be wòawɔ undercuts. Ne ƒuƒoƒoa ƒe ƒuƒoƒo ƒe vovototoa lolo akpa la, woaɖe ga si wotsɔ ƒo ƒu ɖe ƒunukpeƒeawo me dzi akpɔtɔ, eye ele bɔbɔe be woawɔ nusiwo wotso ɖe wo nɔewo ŋu. Le laser welding ƒe nuwuwu la, ne ŋusẽ dzi ɖeɖe kpɔtɔ ƒe ɣeyiɣia le du dzi akpa la, do suea agbã bɔbɔe, si ana be woatso nutoa me le nutoa me. Ŋusẽ kple duƒuƒu dzi kpɔkpɔ be wòasɔ ɖe enu ate ŋu akpɔ kuxi si nye be woaɖe nu le ete la gbɔ nyuie.

5. mumu .

Ne ga si wotsɔ ƒoa gae ƒe duƒuƒu le blewu, ta si wotsɔ ƒoe la lolo eye wòkeke la, ga si wotsɔ ƒoe ƒe agbɔsɔsɔ dzina ɖe edzi, eye eƒe anyigba ƒe tete sesẽna be woalé ga si le abe tsi ene si kpekpe wu la me ɖe asi, weld la ƒe titina anyrɔ, si ana wòagbã kple dowo. Le ɣeyiɣi sia me la, ele be woaɖe ŋusẽ si le eme dzi akpɔtɔ wòasɔ be ta si wotsɔ ƒo ƒu la nagadze anyi o.

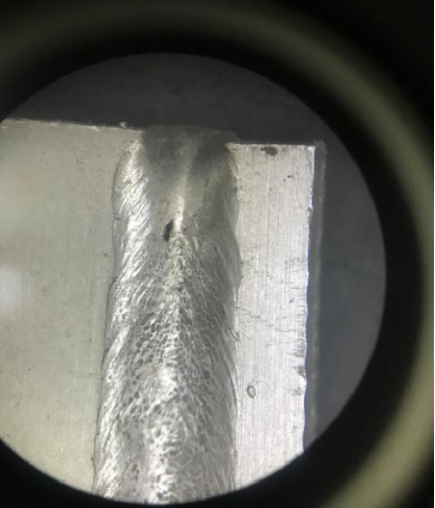

▲Aluminum Alloy weld seam mumuwo .

Gɔmesese nyuie le nusiwo gblẽ le wo ŋu le laser welding ƒe ɖoɖoa me kple nusiwo gbɔ nɔnɔme madeamedzi vovovowo tso gɔmesese ŋu ate ŋu akpe ɖe mía ŋu míakpɔ kuxi si nye weld seams siwo mesɔ o le laser welding me le mɔ si woɖo taɖodzinu na wu nu.