Nezvakanaka zvekubudirira kwakanyanya, zvakanyanyisa, mibairo yakanaka, uye zviri nyore kutakura zvinoshandiswa mukugadzirwa kwakawanda uye kuita zvechiuto, kurapwa, 3c auto auto, uye mechanic simbi. Goridhe, idzva resimba, imba yekugezera uye mamwe maindasitiri.

Nekudaro, chero nzira yekugadzirisa ichabereka zvimwe zvikanganiso kana zvigadzirwa zvine hurema kana zvarinoreva uye maitiro asina kudzidza, uye laser welder haina kusarudzika. Nekunzwisisa chete nekunzwisisa kwakanaka kwezvinhu izvi uye nekudzidza maitiro ekuzvidzivirira kana isu tinganyatso shandura kukosha kweLaser Tolks uye maitiro ezvigadzirwa neyekutaridzika kwakanaka uye chimiro chakakwirira. Timu ye Hangoo Tech (Seko Machinery) akaunganidza nguva yakareba, pamwe nemimwe mitengi mhinduro kubva pakushandisa Laser Welding Stainless Steel Welded Tube Kugadzira Machine , uye akapfupisa mamwe mhinduro kune zvakajairika kutadza kuremara neindasitiri vemashanduri!

1.

Iwo mabundu anogadzirwa mulaser laser alling alerm Matanho akadai sea waya kuzadza uye kufungidzira kunogona kuderedza marara. kana kubvisa marara.

▲ Wakatsiga Wels

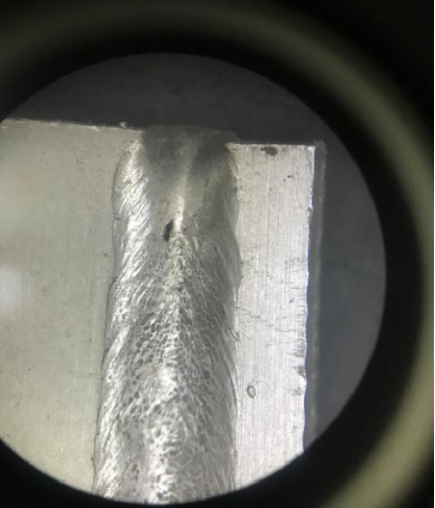

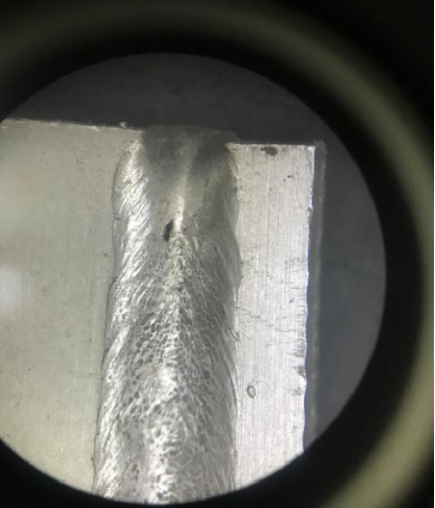

2. Stomata

Kufungisisa kwakaremara kunogadzirwa nyore nyore muLaser welder. Dziva rakanyungudutswa reLaser rakadzika uye rakamanikana, uye chiyero chinotonhorera chiri kukurumidza kwazvo. Iyo gasi inogadzirwa mumvura yakanyungudutswa yakanyungudutswa isina nguva yekupukunyuka, iyo inogona kutungamira nyore kuumbwa kwemapores. Nekudaro, Laser Welding inotonhorera nekukurumidza uye pores yakagadzirwa kazhinji inowanzove diki pane tsika yekufungidzira kwelating. Kuchenesa nzvimbo yebasa usati wasununguka kunogona kuderedza tsika yemapores, uye kutungamira kwekuridza mhere kunochinjawo kuitika kwe pores.

▲ Weld Pores (kuruboshwe)

3. Splash

Iyo spatter inogadzirwa neLaser Welding inokanganisa zvakanyanya kunaka kweiyo weld uye inogona kusvibisa nekukuvadza lens. Spatter inoenderana zvakananga kune simba density, uye nenzira yakakodzera kuderedza simba rinodzikisa spatter. Kana kupinzwa kwakakwana, kumhanya kwekumhanya kunogona kuderedzwa.

▲ Welding Spatter

4. Undercut

Kana kumhanya kwekumhanya kwakanyanya, iyo simbi yemvura kubva kumashure kwegomba diki rinonongedza kusvika pakati peWelk yewaini haizove neyamapuranga, uye ichasimbisa pamativi ese eWelm yekugadzira pasi. Kana musangano wegungano rakanyanya kukura, simbi yakanyungudutswa yekuzadza majoini ichadzikiswa, uye zviri nyore kuburitsa undercuts. Pakupera kweLaser Welding, kana iyo simba kuderera nekukurumidza, gomba diki richadonha zviri nyore, zvichikonzera kuderera kwenzvimbo. Kudzora simba uye kumhanya kuenderana kunogona kubatsira zvakanyanya dambudziko rekunyura.

5. Kudonha

Kana kumhanya kwekunyora kunononoka, dziva rakanyungudutswa rakakura uye rakakura, huwandu hwesimbi hwakaumbwa hunowedzera kuchengeta iyo simbi yakasimba yemvura, iyo nzvimbo yeWelk ichanyura, kugadzira kudonha uye kugadzira makomba. Panguva ino, density density inoda kuve yakaderedzwa nenzira yakakodzera kuti vadzivise dziva rakanyungudutswa.

▲ Aluminium Alloy Weld Seam anowira pasi

Kunyatsonzwisisa kuremara kunogadzirwa panguva yeLaser Welding process uye kunzwisisa zvikonzero zvakasiyana kunogona kutibatsira kugadzirisa dambudziko reWels seams neLaser