Efficiency sang tak, precision sang, result tha tak, leh automation integration awlsam tak te hian laser welding hi industry hrang hrangah hman a ni nasa hle a, industrial production leh manufacturing lamah pawh hmun pawimawh tak a chang a, sipai, medical, aerospace, 3C auto parts, leh mechanical sheet metal te pawh a tel a ni. Gold, energy thar, bathroom hardware leh industry dang dang a awm bawk.

Mahse, eng processing method pawh hian a principle leh process te master loh a nih chuan defect thenkhat emaw defective product thenkhat a siam chhuak ang a, laser welding pawh chutiang bawk chu a ni. Heng chhiatnate hi hriatthiamna tha tak kan neih a, an pumpelh theih dan tur zir chauhvin laser welding leh process products value chu a mawi leh quality sang tak nen kan hmang tangkai thei ang. A team te chu an . HAGAO Tech (Seko Machinery) chuan hun rei tak chhunga tawnhriat a khawlkhawm a, chubakah customer-te ngaihdan thenkhat chu hman a ni bawk. Laser welding stainless steel welded tube forming machine , leh industry thawhpuiten an hman theih tur common welding defects solution thenkhat a khaikhawm bawk!

1. A crack .

Continuous laser welding-a crack siamte chu thermal crack an ni ber a, chu chu crystal crack, liquefaction crack, etc. A chhan ber chu weld hian a solidified vek hmain shrinkage force lian tak a siam chhuak a ni. Wire filling leh preheating ang chi measures te hian a crack te chu a ti tlem thei a ni. A nih loh leh cracks te chu tihbo a ni thei bawk.

▲Cracked Welds .

2. Stomata .

Porosity hi defect a ni a, laser welding-ah pawh awlsam taka siam theih a ni. Laser welding molten pool chu a thuk a, a tawi a, a cooling rate pawh a rang hle bawk. Liquid molten pool-a gas lo chhuak hian tlanchhuahna hun a nei tlem a, chu chuan awlsam takin pores siamna kawngah a hruai thei a ni. Mahse, laser welding chu a lum nghal vat a, pores siam chhuah chu a tlangpuiin traditional fusion welding aiin a te zawk a ni. Welding hmaa workpiece surface tihfai hian pores tendency a ti tlem thei a, blowing direction hian pores lo awm dan a nghawng bawk ang.

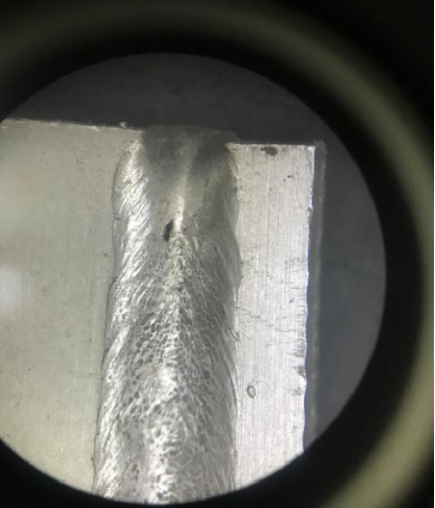

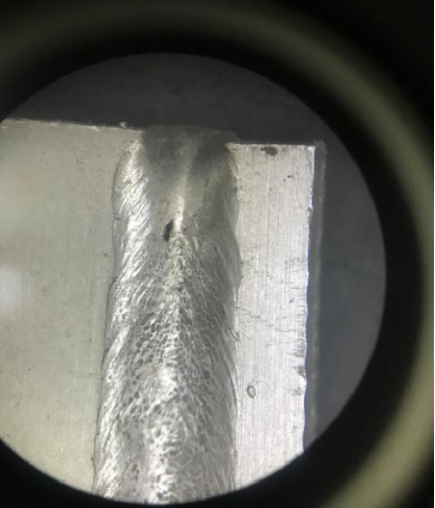

▲Weld pores (khawi lamah nge) .

3. Splash .

Laser welding hmanga spatter siam hian weld surface quality a nghawng nasa hle a, lens a ti bawlhhlawh a, a tichhia thei bawk. Spatter hi power density nen a inzawm tlat a, welding energy tihtlem dan tur dik taka tihtlem chuan spatter a ti tlem thei bawk. Penetration a tlem chuan welding speed pawh a tlahniam thei.

▲Welding Spatter .

4. Undercut .

Welding speed a rang lutuk chuan weld lairil lam hawi khur te tak te hnung lam atanga liquid metal chu redistribute hun a nei dawn lo va, weld sir lehlamah pawh undercut siam turin a solidify ang. Joint assembly gap a lian lutuk chuan joint fill na tur melted metal chu a tlahniam ang a, undercuts siam pawh a awlsam hle ang. Laser welding tawp lamah chuan energy a tlahniam lutuk chuan a khur te tak te chu awlsam takin a tlakbuak ang a, chu chuan local undercut a thlen ang. Power leh speed to match control hian undercut of undercut chu effective takin a chinfel thei a ni.

5. A tlakbuak .

Welding speed a slow chuan molten pool chu a lianin a zau a, molten metal a pung a, a chunglam tension chu liquid metal rit zawk enkawl a harsa a, weld lairil chu a pil ang a, collapses leh pits a siam ang. Hetih lai hian, molten pool a tlakchhiat loh nan energy density chu a remchan dan anga tihtlem a ngai a ni.

▲Aluminum Alloy Weld Seam a tlakbuak .

Laser welding kalpui chhunga chhiatna lo chhuakte dik taka hriatthiam leh chhiatna chi hrang hrang awm chhan hriatthiamna hian laser welding-a weld seam pangngai lo chungchanga harsatna awmte chu target zawka siamin min pui thei a ni.