Nrog rau qhov zoo ntawm kev ua haujlwm siab, muaj txiaj ntsig zoo, thiab kev sib xyaw ua ke ntawm kev lag luam, thiab kev kho kom zoo, arech, thiab cov ntawv siv tshuab). Kub, lub zog tshiab, chav ua haujlwm chav dej thiab lwm yam lag luam.

Txawm li cas los xij, txhua txoj kev ua yuav tsim cov khoom tsis xws luag lossis cov khoom tsis xws yog tias nws cov ntsiab cai thiab cov txheej txheem vuam tsis muaj kev zam. Tsuas yog los ntawm kev nkag siab zoo ntawm cov kev tsis xws thiab kev kawm yuav ua li cas kom zam dhau tus nqi ntawm laser vuam thiab cov khoom lag luam nrog cov tsos zoo nkauj thiab cov khoom lag luam zoo. Pab neeg ntawm Hangao Tech (Seko Machinery) tau sau cov kev paub ntev ntev, nrog rau qee cov neeg siv tswv yim los ntawm kev siv Laser Vuam Stainless Hlau Welded Raj Taus Tshuab , thiab tau nthuav tawm qee cov kev daws teeb meem vuam tsis xws luag rau kev siv los ntawm kev lag luam npawg!

1. Cov kab nrib pleb

Cov kab nrib pleb tsim lag luam yog tsuas yog thermal tawg, thiab lwm yam yog qhov laj thawj loj yog tias cov weld ua rau muaj kev loj hlob loj ua ntej nws ua tiav. Kev ntsuas xws li hlau txhaws thiab preheating tuaj yeem txo cov kab nrib pleb. lossis tshem tawm cov kab nrib pleb.

▲ Nrum pleb

2. Stomata

Porosity yog qhov tsis zoo uas tau yooj yim ua hauv laser vuam. Lub pas dej ua ke ntawm Laser vuam yog sib sib zog nqus thiab nqaim, thiab tus nqi txias txias yog heev. Cov roj tsim tawm hauv cov kua Molten lub sijhawm tsis muaj sijhawm txaus kom khiav tawm, uas tuaj yeem coj tau yooj yim rau kev tsim cov hws. Txawm li cas los xij, laser vuam txias sai thiab cov khoom tsim yog feem ntau me dua li kev siv vuam ua tsoos. Kev ntxuav cov chaw ua haujlwm ua ntej vuam muag tuaj yeem txo cov cwj pwm ntxim nyiam, thiab cov kev taw qhia yuav cuam tshuam rau qhov tshwm sim ntawm pores.

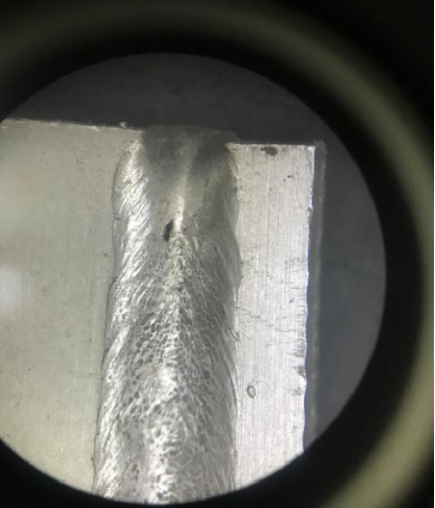

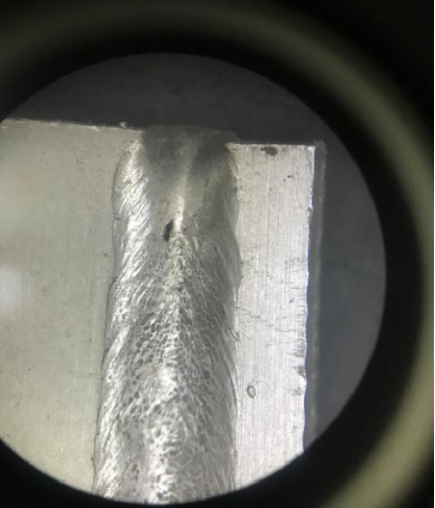

▲ Weld pores (sab laug)

3. Txib

Lub ntsej muag tau tsim los ntawm kev tsim Laser vuam ua rau cov khoom zoo ntawm weld thiab tuaj yeem paug thiab ua kom cov lens puas tsuaj. Nthuav qhia ncaj qha ntsig txog lub hwj chim ntom ntom, thiab txo kev txo hwj chim vuam lub zog tuaj yeem tiv thaiv tau. Yog tias nkag mus yog tsis txaus, lub vuam ceev tuaj yeem txo.

▲ Vuam Spatter

4. Undercut

Yog hais tias lub vuam ceev heev, cov hlau ua kua los ntawm sab nraum qab ntawm lub tsev muag khoom yuav tsis muaj sijhawm los txiav txim siab, thiab yuav ua rau ob tog ntawm Weld los ua cov hauv qab. Yog tias kev sib koom ua ke sib dhos yog qhov loj heev, cov melted hlau rau txhaws cov pob qij txha yuav raug txo kom tsawg, thiab nws yooj yim los tsim cov khoom siv hauv nruab nrab. Thaum kawg ntawm Laser Vuam, yog tias lub zog txo lub sijhawm dhau lawm, lub qhov me me yuav muab cov khoom sib tsoo yooj yim, ua rau muaj kev sib tsoo hauv zos. Kev tswj hwm lub zog thiab nrawm kom phim tuaj yeem daws tau qhov teeb meem ntawm undercut.

5. Collapse

Yog hais tias lub relding ceev yog qeeb, lub pas dej Molten yog qhov nyuaj, thiab qhov ntau ntawm Weld yuav ua tog, sib sau sib tsoo thiab pits. Nyob rau lub sijhawm no, lub zog ntom ntom yuav tsum tau kom txo qis kom tsis txhob ua pas dej ua ke molten.

Aluminium Alloy Weld Seam Collapses

Kev nkag siab yog qhov tsis xws luag rau thaum lub laser vuam txheej txheem thiab nkag siab txog qhov tsis xws luag tuaj yeem pab peb ntawm cov khoom txawv txav weld seaser vuam hauv ib qho kev xav ntau dua.