Nafa minnu bɛ baarakɛcogo ɲuman na, tiɲɛniba, sɔrɔ ɲuman, ani otomatiki doncogo nɔgɔya la, laser welding bɛ baara kɛ kosɛbɛ izini suguya caman na ani a jɔyɔrɔ ka bon kosɛbɛ iziniw dilanni n’u dilanni na, i n’a fɔ sɔrɔdasiw, furakɛli, aerospace, 3C auto yɔrɔw, ani masinw ka nɛgɛw. Sanu, fanga kura, sanuyaso minɛnw ani izini wɛrɛw.

Nka, baarakɛcogo o fɛɛrɛ bɛna kɛ ka fiɲɛ dɔw walima fɛn tiɲɛnen dɔw bɔ ni a sariyakolow n’a kɛcogo ma dɔn, wa laser welding tɛ bɔ o la. Ni an ye nin fiɲɛ ninnu faamuya koɲuman dɔrɔn ani ka u yɛrɛ tangacogo dege, o bɛ se ka baara kɛ ni laser welding ni fɛnw nafa ye ka ɲɛ ni u cogoya ka ɲi ani u ka ɲi. Ekipu min bɛ . Hangao Tech (Seko Machinery) ye waatijan dɔnniya lajɛ, ka fara kiliyanw ka hakilina dɔw kan ka bɔ baara kɛli la . Laser welding inox welded tube forming machine , ani a ye fura dɔw lajɛ ka ɲɛsin welding defects commune ma walasa ka kunnafoni di izini baarakɛɲɔgɔnw fɛ!

1. ka fara .

Fara minnu bɛ Bɔ laser welding continuel la olu ye kɛrɛnkɛrɛnnenya la funteniw ye, i n’a fɔ kristalɛ karilenw, liquefaction cracks, etc. A kunba ye ko welda bɛ fanga belebele dɔ Bɔ ka sɔrɔ a ma Sɔ̀rɔ pewu. Fɛɛrɛ minnu bɛ kɛ i n’a fɔ nɛgɛw falenni ni u sumaya, olu bɛ se ka dɔ bɔ faraw la. walima ka faraw bɔ yen.

▲A ka kan ka kɛ ni welda ye .

2. Stomata .

Porosity ye fiɲɛ ye min bɛ Bɔ nɔgɔya la laser welding na. Laser welding (laser welding) ka ji-yɔrɔ-yɔrɔ bɛ juguya ani ka surunya, wa nɛnɛ hakɛ bɛ teliya kosɛbɛ. Gazi min bɛ bɔ jidaga jilama kɔnɔ, waati tɛ sɔrɔ ka boli, o bɛ se ka kɛ sababu ye ka ɲɛgɛnɛsiraw dilan nɔgɔya la. Nka, laser welding bɛ nɛnɛ joona ani pores minnu bɛ bɔ, a ka c’a la, olu ka dɔgɔ ni laadala fusion welding ye. Ni aw ye baarakɛminɛn ɲɛ saniya sani a ka welding kɛ, o bɛ se ka dɔ bɔ ɲɛgɛnɛsiraw ka teli ka kɛ, wa fiɲɛ bilali sira fana bɛna nɔ bila ɲɛgɛnɛsiraw sɔrɔli la.

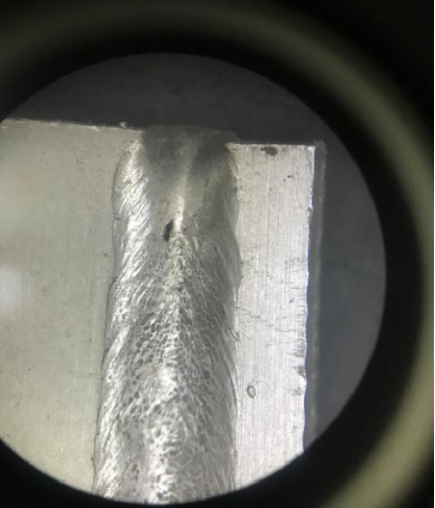

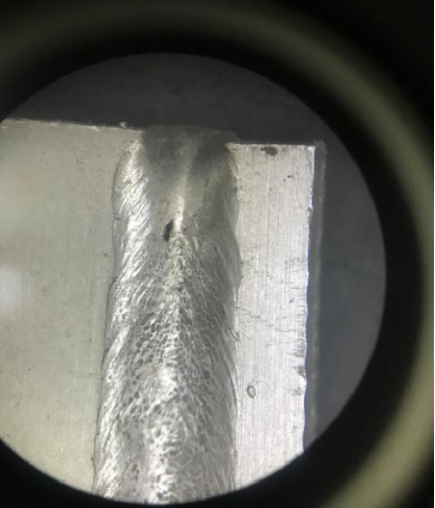

▲Weld Pores (numan fɛ)

3. Splash .

Laser welding bɛ spatter min Bɔ, o bɛ nɔba Blà welda sanfɛla cogoya la wa a bɛ Se ka lensɛri nɔgɔ ani k’a Tiɲɛ. Spatter bɛ tali kɛ fanga hakɛ la, wa a bɛnnen don ka dɔ bɔ welding energy bɛ se ka dɔ bɔ spatter la. Ni doncogo ma se, welding teliya bɛ se ka dɔgɔya.

▲Welding Spatter .

4. Undercut .

Ni welding teliya ka telin, nɛgɛ jilama min bɛ bɔ dingɛ fitinin kɔfɛ min bɛ a ɲɛsin welda cɛmancɛ ma, o tɛna waati sɔrɔ ka tila-tila kokura, wa a bɛna sabati welda fan fila bɛɛ la walasa ka kɛ jukɔrɔla tigɛw ye. Ni joli-sira-funu-yɔrɔ-yɔrɔ ka bon kojugu, nɛgɛ wulilen min bɛ kɛ ka jolidaw fa, o bɛna dɔgɔya, wa a ka nɔgɔn ka jukɔrɔla tigɛ. Laser welding laban na, ni fanga bɛ dɔgɔya waati teliya la, dingɛ fitinin bɛna bin nɔgɔya la, o bɛ na ni sigida jukɔrɔla tigɛ ye. Ni fanga ni teliya min bɛ bɛn ɲɔgɔn ma, o bɛ se ka tiɲɛni gɛlɛya ɲɛnabɔ ka ɲɛ.

5. .

Ni welding teliya bɛ sumaya, pool molten ka bon ani a ka bon, nɛgɛ wulilen hakɛ bɛ caya, ani a sanfɛla girinya ka gɛlɛn ka nɛgɛ jilama gɛlɛn mara, welda cɛmancɛ bɛna jigin, ka kɛ binni ni dingɛw ye. Nin waati in na, fanga hakɛ ka kan ka dɔgɔya cogo bɛnnen na walasa ka a tanga jidagayɔrɔ wulilen ma min bɛ bin.

▲Aluminum alloy weld seam bɛ bin .

Ni an ye fiɲɛw faamuya ka ɲɛ laser welding kɛcogo la ani ka fiɲɛ suguya wɛrɛw sababuw faamuya, o bɛ se k’an dɛmɛ ka gɛlɛya ɲɛnabɔ min ye welda sɔgɔlenw ye laser welding na cogo la min bɛ kɛ ni laɲini ye.