Ngezibonelelo zokusebenza kakuhle, ukuchaneka okuphezulu, iziphumo ezilungileyo, kunye ne-Ilsel yeWeling zisetyenziswa kakhulu kwimizi-mveliso eyahlukeneyo kwaye idlala indima ebaluleke kakhulu kwimibutho yezamashishini kunye nemveliso, i-Aerospace, kunye ne-Auto Spell, kunye ne-Auto Sport, kunye ne-Auto Spell, kunye nePhepha le-Auto. Igolide, amandla amatsha, izixhobo zokuhlambela kunye namanye amashishini.

Nangona kunjalo, nayiphi na indlela yokulungisa iya kuvelisa iziphene ezithile okanye iimveliso ezinesiphene ukuba imigaqo-siseko kunye neenkqubo zayo azikwaziyo, kwaye i-laser ye-laser ayifani. Kuphela ngokuqonda okuhle kwezi ziphene kunye nokufunda indlela yokuphepha ukuba singasebenzisa ngcono ixabiso le-wels yelding kunye nenkqubo yemveliso enomfanekiso omnandi kunye nomgangatho ophezulu. Iqela le I-Hingao Tech (Matshini weSeko) iqokelele amava exesha elide, kunye nengxelo yomthengi ovela ekusebenziseni I-Laser Welling ye-Stained Stained I-Tube Deel Deed Dube , kwaye ishwankathele ezinye izisombululo zesiphene esiqhelekileyo selding ukulungiselela abalingane bemigangatho!

I-1. Rocks

Imingxunya eyenziwe kwi-ilser eqhubekayo i-rocks icwecwe, ezinje ngotywala obukhali, i-rockings, njl njl, njl njl. Amanyathelo anje ngendawo yokugcwalisa ucingo lokugcwalisa kunye nokuchasa kunokunciphisa imifula. okanye ukuphelisa imifula.

▲ i-wels eqhekekileyo

2. I-Stomata

I-Porosity inesiphene esiveliswa ngokulula kwi-laser welding. Iphuli yecoln etyhidiweyo ye-laser yelding inzulu kwaye imxinwa, kwaye inqanaba lokupholisa likhawuleza kakhulu. Igesi eyenziwe kwiphuli ye-nyibilikisi ayinaxesha elaneleyo lokubaleka, enokukhokelela ngokulula ekumiselweni kweepores. Nangona kunjalo, i-laser yelding upholile ngokukhawuleza kwaye iipores ziveliswe ngokubanzi zincinci kune-fusion yemveli. Ukucoca umphezulu we-Worpiece ngaphambi kokuba i-welding inokunciphisa umkhwa we-pores, kwaye indlela yokubetha iya kuchaphazela ipores.

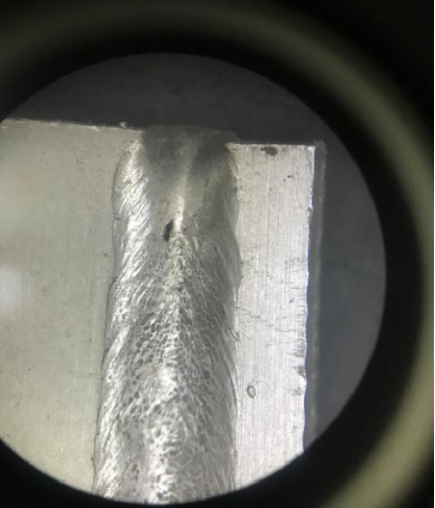

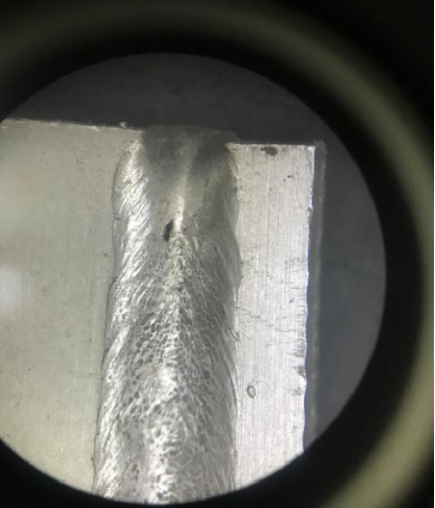

▲ I-Weld Poors (ngasekhohlo)

I-3. Splash

I-Spatter eveliswe nguLaser Welding ichaphazela umgangatho womhlaba we-weld kwaye inokungcolisa kwaye yonakalise ilensi. I-spatter ihambelana ngqo nengxinano yamandla, kwaye ukunciphisa ngokufanelekileyo amandla eWeding kungayinciphisa spatter. Ukuba ukungena awonelanga, isantya se-welding sinokuncitshiswa.

▲ welding spatter

I-4. Iphantsi

Ukuba isantya se-welding sikhawuleza kakhulu, isinyithi solwelo ngasemva komngxunya omncinci obonisa iziko le-WASTld aliyi kuba nexesha lokusasaza, kwaye baya kukodwa kumacala omzimba ukuze benze i-shdcuts. Ukuba i-Gap yeNdibano edibeneyo inkulu kakhulu, inyibilikisi enyibilikisiweyo yokugcwalisa amalungu iya kuncitshiswa, kwaye kulula ukuvelisa i-zurcuts. Ekupheleni kwe-laser yelding, ukuba amagalelo ancipha ixesha likhawuleza kakhulu, umngxunya omncinci uya kuwa ngokulula, okukhokelela kwingingqi yengingqi. Ukulawula amandla kunye nesantya sokutshata ngokuhambelana kunokusombulula ngokufanelekileyo ingxaki yokuphezulu.

5. Ukuwa

Ukuba isantya se-welding sicothise, iphuli etyhidiweyo inkulu kwaye ibanzi, ubungakanani bonyuka kwentsimbi eshukumayo, kwaye imbambano yomphezulu kunzima ukuyigcina, ikhuselo le-weld liza kunqisa, ukwenza imingxunya. Ngeli xesha, ukuxinana kwamandla kufuneka kuncitshiswe ngokufanelekileyo ukunqanda iphuli yecoln.

I-Aluminium Alld Seam

Ukuqonda ngokuchanekileyo iziphene eziveliswe ngexesha lenkqubo ye-laser ye-laser ye-laser kunye nokuqonda iziphene ezahlukeneyo kunokusinceda ukusombulula ingxaki ye-Woldrial Seams kwi-larneged ngendlela ekujoliswe kuyo.