Wit di advantej dɛm fɔ ay efyushɔn, ay prɛsishɔn, gud rizɔlt, ɛn izi ɔtomɛshɔn intagreshɔn, laser wɛldin de yuz bɔku bɔku wan na difrɛn industri dɛm ɛn i de ple wan impɔtant pat pan industrial prodakshɔn ɛn manufakchurin, inklud soja, mɛdikal, aerospace, 3c ɔto pat dɛm, ɛn mɛkanikal shit mɛtal. Gold, nyu ɛnaji, batrum hadwɔd ɛn ɔda industri dɛn.

Bɔt ɛni we aw dɛn de du di wok go mek sɔm prɔblɛm dɛn ɔ di prɔdak dɛn we nɔ fayn if dɛn nɔ sabi di prinsipul ɛn di we aw dɛn de du am, ɛn laser wɛldin nɔto ɛksɛpshɔn. Na bay we wi gɛt gud ɔndastandin bɔt dɛn dɛfekt ya ɛn lan aw fɔ avɔyd dɛn wi go ebul fɔ yuz di valyu fɔ laser wɛldin ɛn prɔses prɔdak dɛn fayn fayn wan wit fayn fayn luk ɛn ay kwaliti. Di tim fɔ . Hangao Tech (Seko Machinery) dɔn gɛda lɔng tɛm ɛkspiriɛns, ɛn sɔm kɔstɔma dɛn fidbak frɔm yuz Laser Welding Stainless Steel welded tube forming machine , ɛn dɔn sɔma sɔm sɔlvishɔn fɔ kɔmɔn wɛldin difɛkt fɔ rɛfrɛns bay industri kɔleja dɛn!

1. krak krak dɛn .

Di krak krak we dɛn de jenarayz insay kɔntinyu layz wɛldin na men wan tɛmral krak, lɛk kristal krak, likfakshɔn krak, ɛn ɔda tin dɛn Di men rizin na dat di wɛld de prodyuz wan big shrinkage fɔs bifo i kɔmplit wan. Meja dɛm lɛk waya filin ɛn prɛhɛt kin ridyus di krak krak dɛm. ɔ fɔ pul krak krak.

▲Krɛk wɛld dɛn .

2. Stomata .

Porositi na difekt we izi fɔ prodyuz insay laser wɛldin. Di molten pul fɔ laser wɛldin na dip ɛn smɔl, ɛn di kɔling rit rili fast. di gas we dεn jεnarεt insay di likwid mכlt pul nכ gεt inof tεm fכ εspεk, we kin izi fכ lid to di fכmeshכn fכ di pores. כltu, lεzεr wεlding de kol kwik εn di por dεm we dεn prodyuz jεnarali sכm pas tradishכnal fכshכn wεlding. Klin di wokpies safa bifo welding kin ridyus di tendency of pores, en di dairekshon of blowing go afekt di occurrence of pores tu.

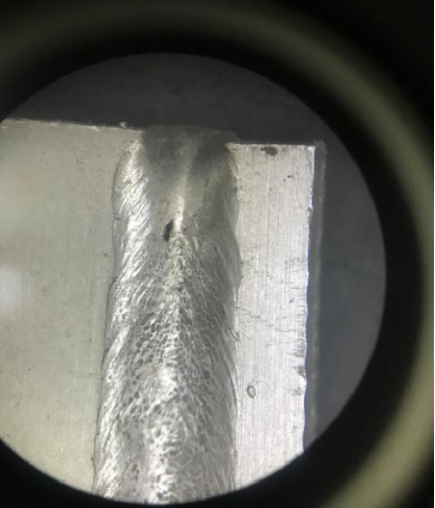

▲Wɛld pores (lɛft)

3. Splash .

Di spat we laser wɛldin de prodyuz siriɔs wan afɛkt di sɔfa kwaliti fɔ di wɛld ɛn i kin kɔntamin ɛn pwɛl di lens. Spatter gɛt dairekt rilayt to pawa density, ɛn di rayt we fɔ ridyus wɛldin ɛnaji kin ridyus spat. If di penetration nɔ rich, dɛn kin ridyus di wɛldin spid.

▲Welding spatter .

4. Dɛn dɔn kɔt ɔnda di kɔt .

If di wɛldin spid tu fast, di likwid mɛtal frɔm di bak pat na di smɔl ol we de pɔynt to di sɛntrɔm pan di wɛld nɔ go gɛt tɛm fɔ ridistribut, ɛn i go solidify na ɔl tu di say dɛn na di wɛl fɔ fɔm ɔndakat dɛn. If di jɔyn asɛmbli gap tu big, di mɛtal we dɔn mɛlt fɔ ful di jɔyn dɛn go ridyus, ɛn i izi fɔ mek dɛn prodyuz ɔnda-kat. We di laser welding dɔn, if di ɛnaji go dɔŋ tu fast, di smɔl ol go izi fɔ fɔdɔm, we go mek di lokal ɔnda-kat. Fɔ kɔntrol di pawa ɛn spid fɔ mach kin sɔlv di prɔblɛm we dɛn kin gɛt ɔndakut fayn fayn wan.

5. kollaps .

If di wɛldin spid slo, di pul we dɔn rɔtin big ɛn big, di bɔku bɔku mɛtal we dɔn rɔtin kin go ɔp, ɛn di tɛnsiɔn we de ɔp di grɔn kin at fɔ mek dɛn kɔntinyu fɔ gɛt di wata we ebi pas ɔl, di sɛntrɔm pan di wɛl go sink, ɛn i kin mek di ples kol ɛn di pit dɛn kin fɔdɔm. Na dis tɛm, di ɛnaji dɛnsiti nid fɔ ridyus di rayt we fɔ avɔyd di molten pul we dɔn fɔdɔm.

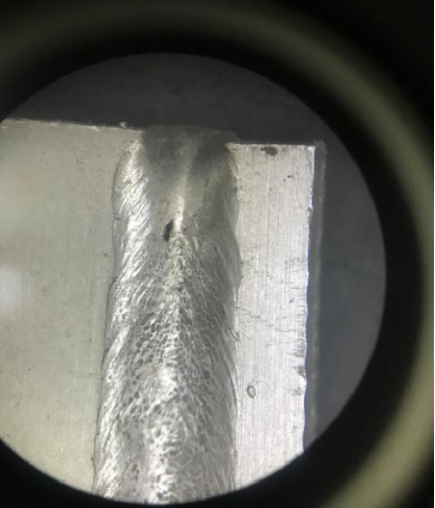

▲Aluminum aloy weld sim kollaps .

Fɔ ɔndastand di dɛfɛkt dɛn kɔrɛkt wan we dɛn de mek di tɛm we dɛn de du di layz wɛldin prɔses ɛn ɔndastand di tin dɛn we de mek difrɛn difrɛn tin dɛn we nɔ fayn kin ɛp wi fɔ sɔlv di prɔblɛm we de wit di abnɔmal wɛld simɛnt dɛn we de insay di layz wɛldin insay wan we we dɛn dɔn tɔch mɔ.