Ngezinzuzo zokusebenza okuphezulu, ukunemba okuphezulu, imiphumela emihle, kanye nokuhlanganiswa okulula okuzenzakalelayo, i-laser welding isetshenziswa kabanzi ezimbonini zezimboni futhi idlala amasosha, kanye ne-mechage shipe insimbi. Igolide, amandla amasha, i-hardware yokugezela kanye nezinye izimboni.

Kodwa-ke, noma iyiphi indlela yokucubungula izokhiqiza iziphambeko ezithile noma imikhiqizo ethile uma izimiso zayo nezinqubo zayo zingaziwa, futhi i-laser welding ayifani. Kuphela ngokuqonda kahle kwalezi zinkinga nokufunda ukuthi ungazigwema kanjani kangcono ukusebenzisa inani le-laser welding kanye nemikhiqizo yenqubo ngokubukeka okuhle nekhwalithi ephezulu. Iqembu le I-Hanao Tech (Seko Imishini) inqoqele isipiliyoni sesikhathi eside, kanye nempendulo ethile yamakhasimende ekusebenziseni I-Laser Welding Insimbi Engahleliwe ye-Welded Tube yakha umshini , futhi isifingqene nezisombululo ezithile kwiziphene ezijwayelekile ze-welding ukuze zibhekise ozakwabo embonini!

1. Imifantu

Imifantu ekhiqizwe e-laser ye-laser eqhubekayo ikakhulukazi imifantu eshisayo, njengokuqhekeka kwe-crystal, imifantu ye-liquefal, njll. Isizathu esiyinhloko ukuthi iWeld ikhiqiza amandla amakhulu okuthi i-shrinkage ngaphambi kokuthi iqinisekiswe ngokuphelele. Izinyathelo ezinjengokugcwaliswa kocingo nokuqala ukugcwala kunganciphisa imifantu. noma ususe imifantu.

▲ ama-welds aqhekekile

2. I-Stomata

I-porolity isici esikhiqizwa kalula eLaser Welding. I-molten pool of laser welding ijulile futhi incane, futhi izinga lokupholisa lishesha kakhulu. Igesi ekhiqizwe echibini elicwengekileyo lingenaso isikhathi esanele sokuphunyuka, esingaholela kalula ekwakhekeni kwama-pores. Kodwa-ke, i-laser welding ipholisa ngokushesha futhi ama-pores akhiqizwa ngokuvamile ancanyana kune-fusion ye-fusion yendabuko. Ukuhlanza indawo yokusebenza ngaphambi kokushiswa kunganciphisa ukuthambekela kwama-pores, futhi ukuqondiswa kokushaya kuzothinta nakho okuvela kwama-pores.

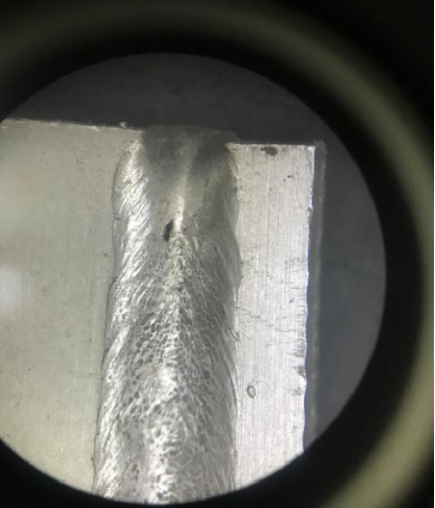

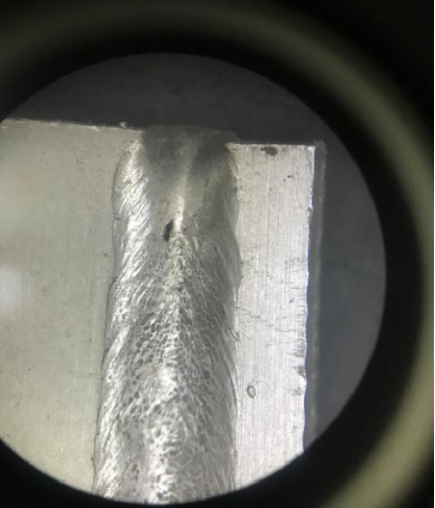

▲ ama-pores we-weld (kwesobunxele)

3. Splash

I-spate ekhiqizwe nguLaser Welding ithinta kakhulu ikhwalithi ephezulu ye-weld futhi ingangcolisa ilensi. I-Spatter ihlobene ngokuqondile nobunzima bamandla, futhi ukunciphisa amandla ancishisiwe kunganciphisa i-spatter. Uma ukungena kwe-penet akwanele, ijubane le-welding lingancishiswa.

Spatter welding

4. Undercut

Uma isivinini se-welding sishesha kakhulu, i-wequid yensimbi evela emuva emgodini omncane ikhomba maphakathi neWeld ngeke ibe nesikhathi sokwabiwa kabusha, futhi izoqina zombili izinhlangothi ze-weld ukuze isebenze. Uma igebe lomhlangano elihlanganayo likhulu kakhulu, insimbi encibilikisiwe yokugcwalisa amalunga izoncishiswa, futhi kulula ukukhiqiza ama-undercuts. Ekupheleni kwe-laser welding, uma isikhathi sokunciphisa amandla sishesha kakhulu, umgodi omncane uzowa kalula, okuholela ekufutheni kwasendaweni. Ukulawula amandla nesivinini sokufanisa kungaxazulula ngempumelelo inkinga yokungaphansi.

5. Ukuwa

Uma ijubane le-welding lihamba kancane, ichibi elibunjiwe likhulu, inani le-molan Metal lenyuka, futhi ukungezwani okubunjiwe kunzima ukugcina insimbi enzima ye-liquid, maphakathi nendawo ye-weld kuzocwila, kwakha ukuwa kwe-dits. Ngalesi sikhathi, ukuqina kwamandla kudinga ukwehliswa ngokufanele ukugwema ichibi elibunjiwe liwele.

I-alumininum alloy weld seld iyawa

Ukuqonda kahle iziphambeko ezikhiqizwe ngesikhathi senqubo ye-laser welding kanye nokuqonda izimbangela zeziphambeko ezahlukahlukene kungasisiza ukuba sixazulule inkinga yama-selding we-laser welding ngendlela ehlosiwe ngokwengeziwe.