With the advantages of high efficiency, high precision, good results, and easy automation integration, laser welding is widely used in various industries and plays a pivotal role in industrial production and manufacturing, including military, medical, aerospace, 3C auto parts, and mechanical sheet metal. Gold, new energy, bathroom hardware and other industries.

However, any processing method will produce certain defects or defective products if its principles and processes are not mastered, and laser welding is no exception. Only by having a good understanding of these defects and learning how to avoid them can we better utilize the value of laser welding and process products with beautiful appearance and high quality. The team of Hangao Tech (SEKO Machinery) has accumulated long-term experience, as well as some customer feedback from using laser welding stainless steel welded tube forming machine, and has summarized some solutions to common welding defects for reference by industry colleagues!

1. Cracks

The cracks generated in continuous laser welding are mainly thermal cracks, such as crystal cracks, liquefaction cracks, etc. The main reason is that the weld produces a large shrinkage force before it is completely solidified. Measures such as wire filling and preheating can reduce the cracks. or eliminate cracks.

▲Cracked welds

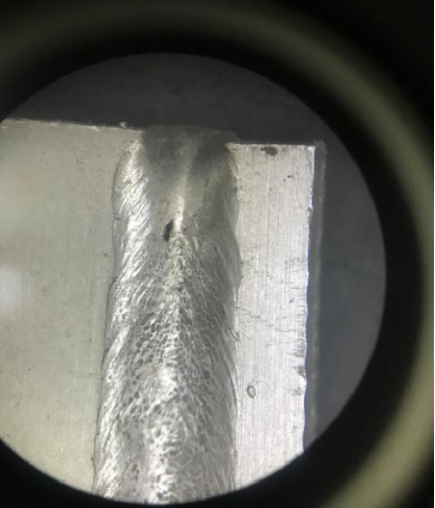

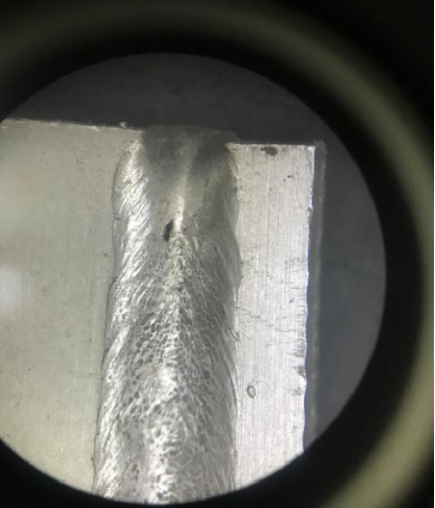

2. Stomata

Porosity is a defect that is easily produced in laser welding. The molten pool of laser welding is deep and narrow, and the cooling rate is very fast. The gas generated in the liquid molten pool does not have enough time to escape, which can easily lead to the formation of pores. However, laser welding cools quickly and the pores produced are generally smaller than traditional fusion welding. Cleaning the workpiece surface before welding can reduce the tendency of pores, and the direction of blowing will also affect the occurrence of pores.

▲Weld pores (left)

3. Splash

The spatter produced by laser welding seriously affects the surface quality of the weld and can contaminate and damage the lens. Spatter is directly related to power density, and appropriately reducing welding energy can reduce spatter. If penetration is insufficient, the welding speed can be reduced.

▲Welding spatter

4. Undercut

If the welding speed is too fast, the liquid metal from the back of the small hole pointing toward the center of the weld will not have time to redistribute, and will solidify on both sides of the weld to form undercuts. If the joint assembly gap is too large, the melted metal for filling the joints will be reduced, and it is easy to produce undercuts. At the end of laser welding, if the energy decrease time is too fast, the small hole will easily collapse, resulting in local undercut. Controlling the power and speed to match can effectively solve the problem of undercut.

5. Collapse

If the welding speed is slow, the molten pool is large and wide, the amount of molten metal increases, and the surface tension is difficult to maintain the heavier liquid metal, the center of the weld will sink, forming collapses and pits. At this time, the energy density needs to be appropriately reduced to avoid The molten pool collapsed.

▲Aluminum alloy weld seam collapses

Correctly understanding the defects produced during the laser welding process and understanding the causes of different defects can help us solve the problem of abnormal weld seams in laser welding in a more targeted manner.